Shredding and Recycling of Agricultural Films

Robust Shredders for Farm Plastics like Silage Wraps, Greenhouse Films & More

The use of agricultural films has been increasing for decades and the market continues to grow. The reasons for this are the increasing demand for food and animal feed, decreasing acreage, soil protection and the cost efficiency of agricultural films. As there are currently hardly any alternatives, consumption is leading to more and more film waste. Only efficient film recycling offers a sustainable solution. Shredding to a homogeneous grain size is essential for this - the first step in the recycling process.

WEIMA shredders are specially designed for the material processing of post-consumer agricultural film and are based on decades of experience in plastics recycling in the agricultural sector.

Customer applications: Agricultural film shredding with WEIMA

Practical examples of successful shredding with WEIMA shredders

Want to tackle your waste problem?

Request a customized shredding solution now.

WEIMA portfolio for shredding agriculture film

The right machine for every material

Heavy duty machine design

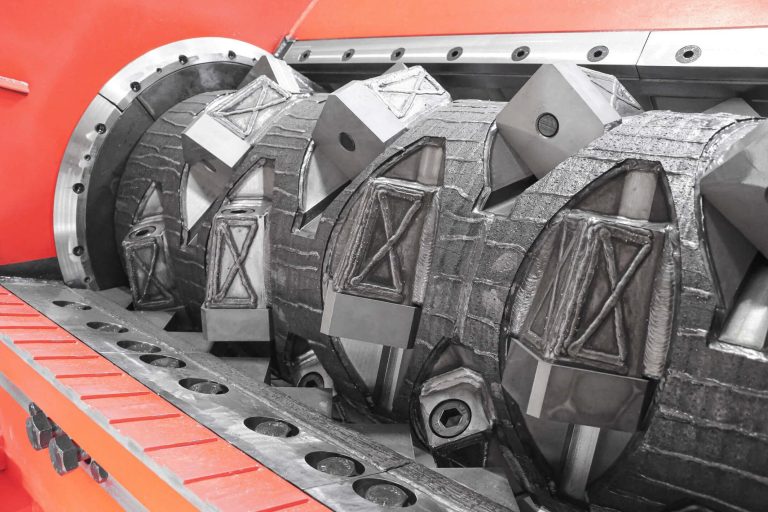

WEIMA shredders for highly abrasive materials can be equipped with numerous options to protect against wear – for less downtime and lower maintenance costs. The solid machine frame ensures particular robustness. Rotors can be reinforced with Vautid and screens with Creusabro. Optionally, large knives (up to 130 x 130 mm) protect against foreign bodies, Vautid can also secure knife carriers.

To protect the rotor face plates, we recommend replaceable Creusabro wear plates that can be fitted on both sides. The cutting chamber can also be optionally reinforced with replaceable Creusabro plates. For particularly heavy-duty applications, we offer an approx. 20 mm thick, wear-resistant Creusabro screen.

This is what makes film shredding so challenging:

Only half of the material delivered is actually film. Contaminants such as soil, stones, sand and feed residues account for over 45 percent.

Developed for flat materials such as films: The F-Rotor

The optimum coordination of rotor, knives and counter knives is crucial for the shredding result. The selection of the components suitable for the material requires a high degree of experience. The F-rotor, specially designed for films, is characterized by its controlled feeding behavior.

By the way: For particularly abrasive or dirty materials, we recommend wear protection made of Vautid.

WEIMA F-rotor

Example applications for the sustainable disposal of agricultural films

Inquire about an agriculture film shredder today

Request a quote

Recycling agricultural films, silage films or stretch films

The most important facts at a glance

Plasticulture: challenge and opportunity

With the increasing modernization of agriculture, the use of plastics such as agricultural, stretch and greenhouse films is on the rise – a trend known as plasticulture. This increases yields, but also leads to more and more film waste.

Thanks to modern shredding technology, for example from WEIMA, used crop plastics can be recycled efficiently. New agricultural and construction films as well as products such as fences, hoses or bin liners are created from the recycled pellets – in line with the circular economy.

This closes the film cycle, saves oil and protects the environment – to the benefit of agriculture and nature.

Agriculture film in use on field

WEIMA also shreds agricultural nonwovens

In addition to agriculture film, agricultural non-woven fabric is also frequently used on farms to ensure a good harvest even under extreme weather conditions. Early weeding nonwoven, weed nonwoven and frost protection nonwoven are made of high-quality polypropylene (PP) yarn and can usually be used for several years.

After that, they are recyclable, just like film, and are first shredded with the help of WEIMA shredders.

See for yourself.

Have your material tested free of charge in our test center.

Practical examples and references | Agricultural film recycling with WEIMA

WEIMA shredders are synonymous with efficient plastics recycling worldwide including at

Plastika Kritis

CEDO Recycling

Frequently Asked Questions about agricultural film shredding

Everything you need to know about safely and efficiently shredding agriculture film.

Can these shredders handle dirty agricultural films, or do I need to pre-clean them?

Yes. WEIMA shredders are engineered to process highly contaminated agricultural films without the need for pre-cleaning. The PreCut 3000, shown processing LDPE stretch film with contamination levels around 20–25%, uses a hydraulic drive and wear-protected rotor to keep difficult material moving. The W5.18 is also proven in real plant conditions for LDPE film. While cleaner input reduces wear, spotless film is not required before shredding.

What is the difference between the W5.18 and the PreCut 3000 for film recycling?

The W5.18 is a versatile single-shaft shredder suited for LDPE films and bulky plastics like tanks and barrels. It features a hydraulically upward-swiveling screen basket and an inspection flap for easy access and fast removal of foreign objects. The PreCut 3000, by contrast, is built for very dirty films, high throughput, and heavy contamination. It uses a powerful Hägglunds Bosch Rexroth hydraulic drive and a massive rotor with Vautid wear protection, making it ideal as a pre-shredder in multi-stage lines.

What happens if there are stones or bits of metal in the film?

These shredders are designed to tolerate unexpected foreign objects in agricultural films. On the W5.18, an inspection flap allows quick removal of stones, metal pieces, or other contaminants. The PreCut 3000 goes further with a hydraulic drive and wear-protected rotor, engineered for unpredictable loads in highly contaminated material streams. These features help keep production running and reduce downtime when contaminants appear.

What kind of output size should I expect from shredding film?

The output consists of uniform, homogeneous pieces suitable for washing and downstream processing. The final size is defined by the screen beneath the rotor. On the W5.18, the hydraulically swiveling screen basket provides both precise size control and faster access for screen changes and chamber cleaning. This ensures consistent flakes ready for the next process steps.

Is this suitable for silage wrap and stretch film?

Yes. WEIMA shredders are designed specifically for post-consumer agricultural films such as silage wrap and stretch film. The machines highlighted on this page demonstrate LDPE and stretch film processing under real-world contamination levels. Their robust design and material handling systems allow reliable operation even with dirt, residues, and organic contamination typical of agricultural use.

What should I consider when choosing a shredder for my film?

Key considerations include film type, contamination level, and required throughput. For extremely dirty films or multi-stage recycling systems, the PreCut 3000 is ideal due to its heavy-duty hydraulic drive and high throughput. For flexible use with LDPE films and other plastics, the W5.18 provides a versatile single-shaft solution. Features like an inspection flap and swiveling screen basket simplify daily operation and maintenance.

How is maintenance handled on these machines?

Maintenance is designed to be simple and efficient. The W5.18 features a hydraulically upward-swiveling screen basket for fast access to the cutting chamber, and an inspection flap for quick removal of foreign objects. The PreCut 3000 uses a rotor with Vautid wear protection to withstand abrasive loads and extend service life. These design features help reduce downtime and keep operating costs predictable.

What are you looking for?

Explore all WEIMA solutions