-

A.200

![]()

Label press

Explore Machine -

A.250

![]()

Label press

Explore Machine -

A.300

![]()

Label press

Explore Machine -

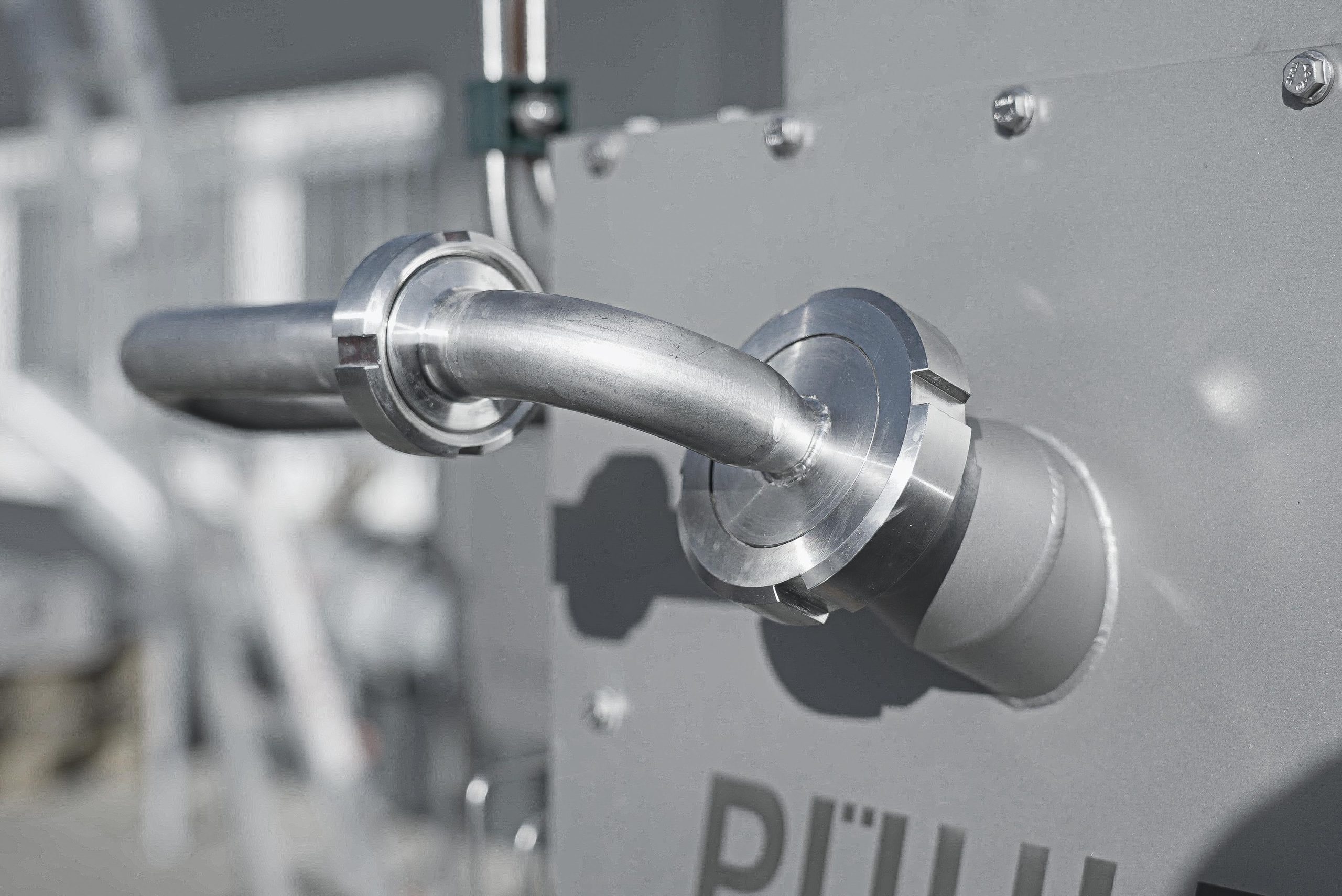

C.200

![Metal swarf and plastic turnings press PUEHLER C.200 from WEIMA]()

Chip press

Explore Machine -

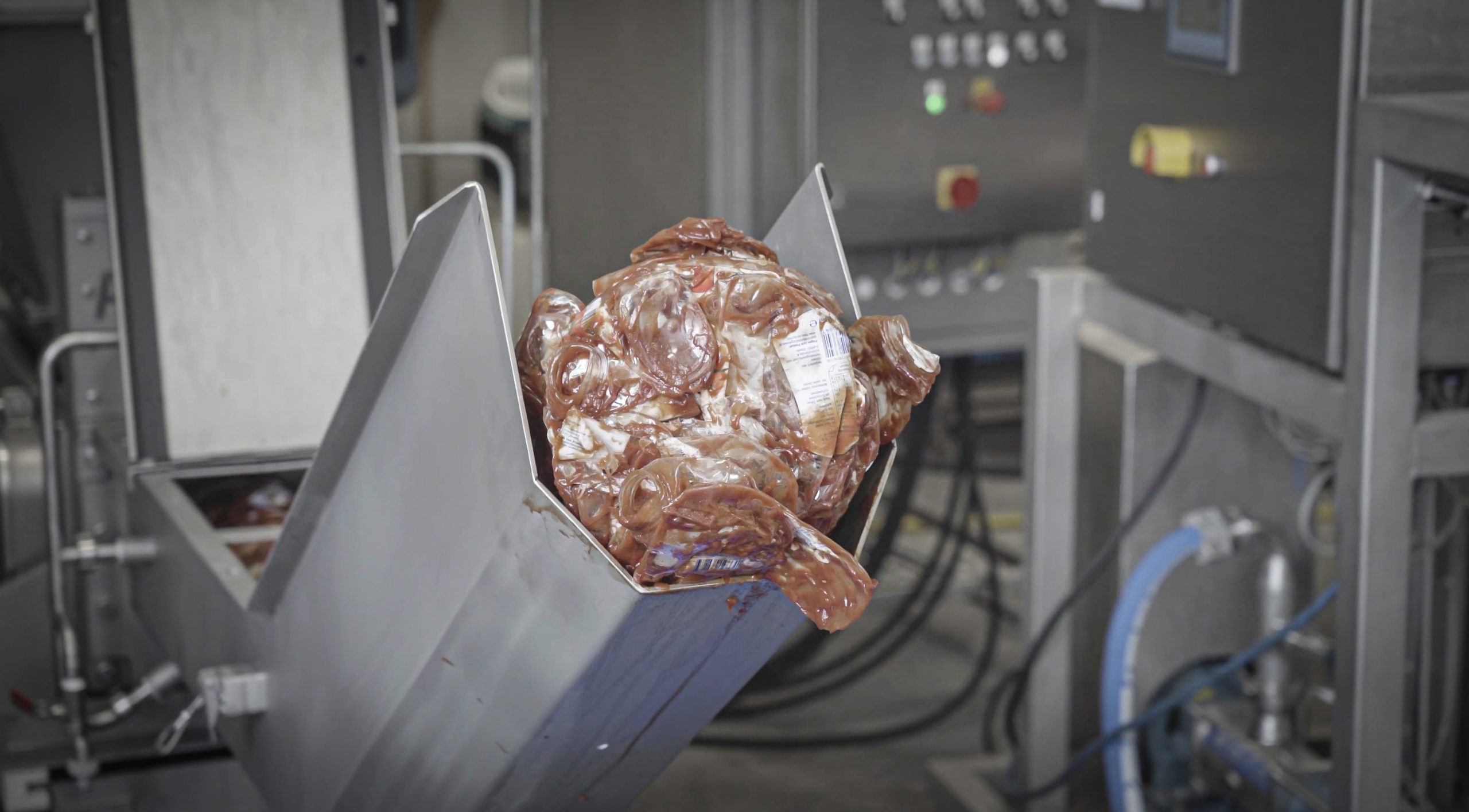

E.200

![WEIMA PUEHLER E.200 press]()

Packaging press

Explore Machine -

E.300

![WEIMA PUEHLER E.200 press]()

Packaging press

Explore Machine -

G.200

![]()

Drainage press

Explore Machine -

G.300

![]()

Drainage press

Explore Machine -

G.300 Duo

![]()

Drainage press

Explore Machine

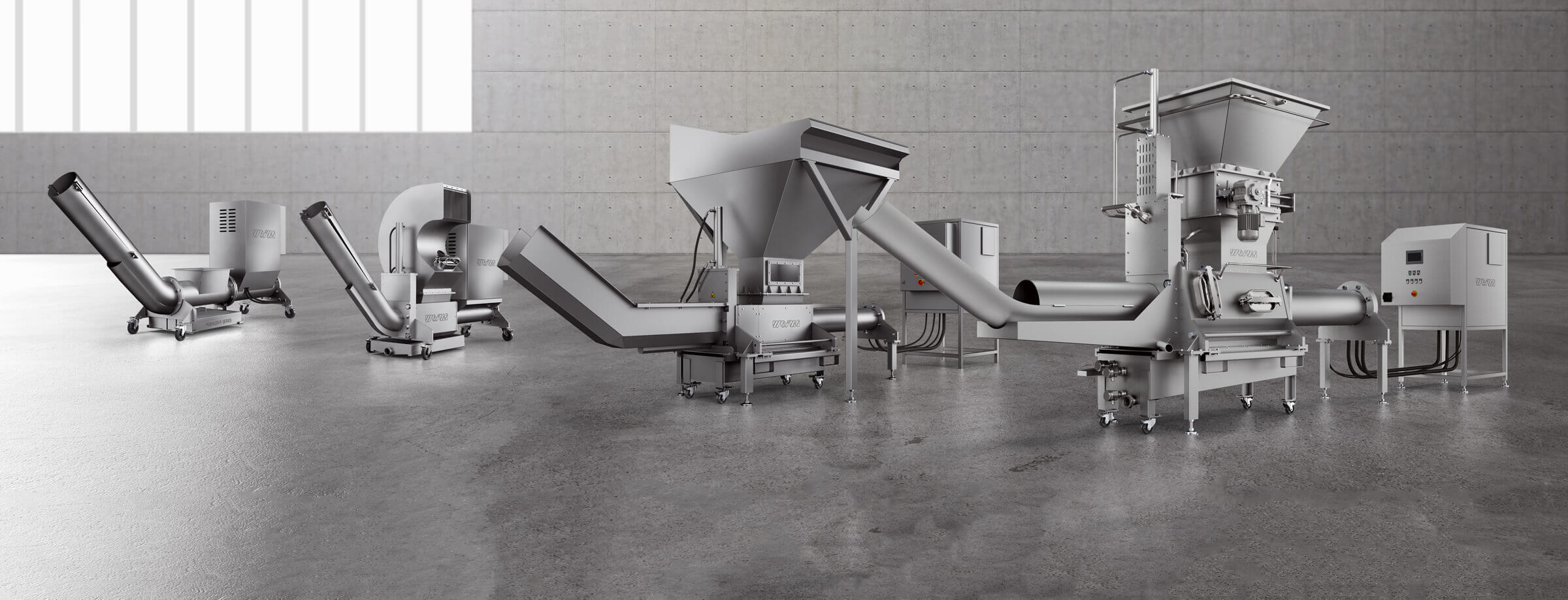

Series

Presses

This series contains label presses, can presses, recycling and packaging presses, and chip presses