-

WL 600

![]()

Single-shaft shredder

Explore Machine -

WL 4

![]()

Single-shaft shredder

Explore Machine -

WL 6

![]()

Single-shaft shredder

Explore Machine -

WL 6 S

![]()

Single-shaft shredder

Explore Machine -

WL 8

![]()

Single-shaft shredder

Explore Machine -

WL 10

![]()

Single-shaft shredder

Explore Machine -

WL 15

![]()

Single-shaft shredder

Explore Machine -

WL 20

![WL 20 single-shaft shredder from WEIMA]()

Single-shaft shredder

Explore Machine

Series

WL

Proven standard machines with bolted screen and belt drive

-

WLK 4

![]()

Single-shaft shredder

Explore Machine -

WLK 6 S

![]()

Single-shaft shredder

Explore Machine -

WLK 800

![Der WEIMA WLK 800 Einwellen-Shredder]()

Single-shaft shredder

Explore Machine -

WLK 10

![]()

Single-shaft shredder

Explore Machine -

WLK 1000

![WEIMA WLK 1000 single-shaft shredder for plastic waste]()

Single-shaft shredder

Explore Machine -

WLK 15

![]()

Single-shaft shredder

Explore Machine -

WLK 1500

![]()

Single-shaft shredder

Explore Machine -

WLK 20

![WLK 20 single-shaft shredder from WEIMA]()

Single-shaft shredder

Explore Machine -

WLK 2000

![WLK 2000 single-shaft shredder from WEIMA]()

Single-shaft shredder

Explore Machine

Series

WLK

Universally usable industrial shredders with multiple options

-

W5.14

![Produktbild des weima w5.18 shredders]()

Single-shaft shredder

Explore Machine -

W5.18

![WEIMA industrial shredder W5.18]()

Single-shaft shredder

Explore Machine -

W5.22

![Produktbild des weima w5.18 shredders]()

Single-shaft shredder

Explore Machine

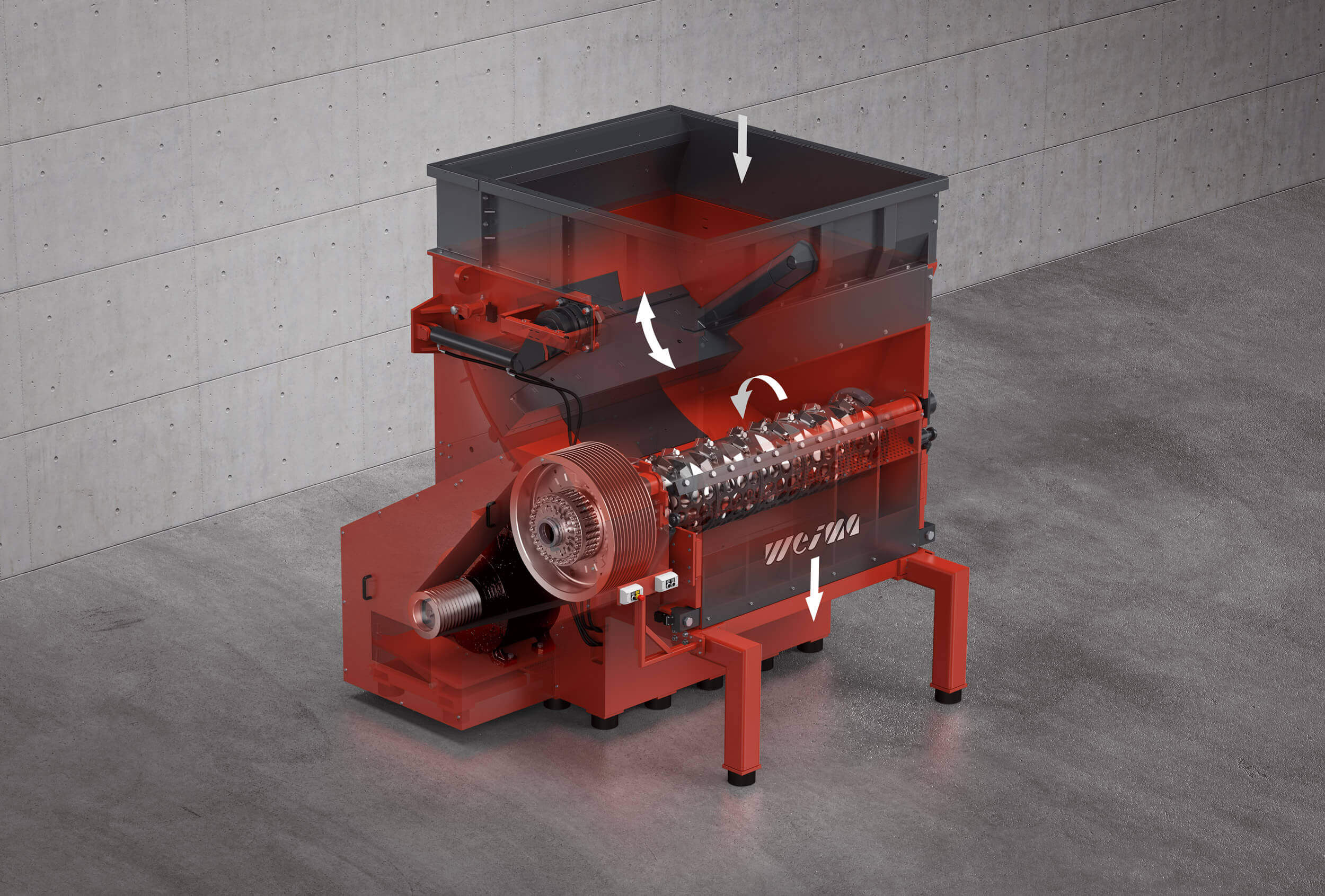

Series

W5

Flexible productive machines with swing ram and inspection flap

-

S5.15 lift-up

![]()

Single-shaft shredder

Explore Machine -

S5.20 lift-up

![]()

Single-shaft shredder

Explore Machine -

S5.25 lift-up

![]()

Single-shaft shredder

Explore Machine -

S7.15 lift-up

![WEIMA shredder für Kunststoffe vor grauer wand]()

Single-shaft shredder

Explore Machine -

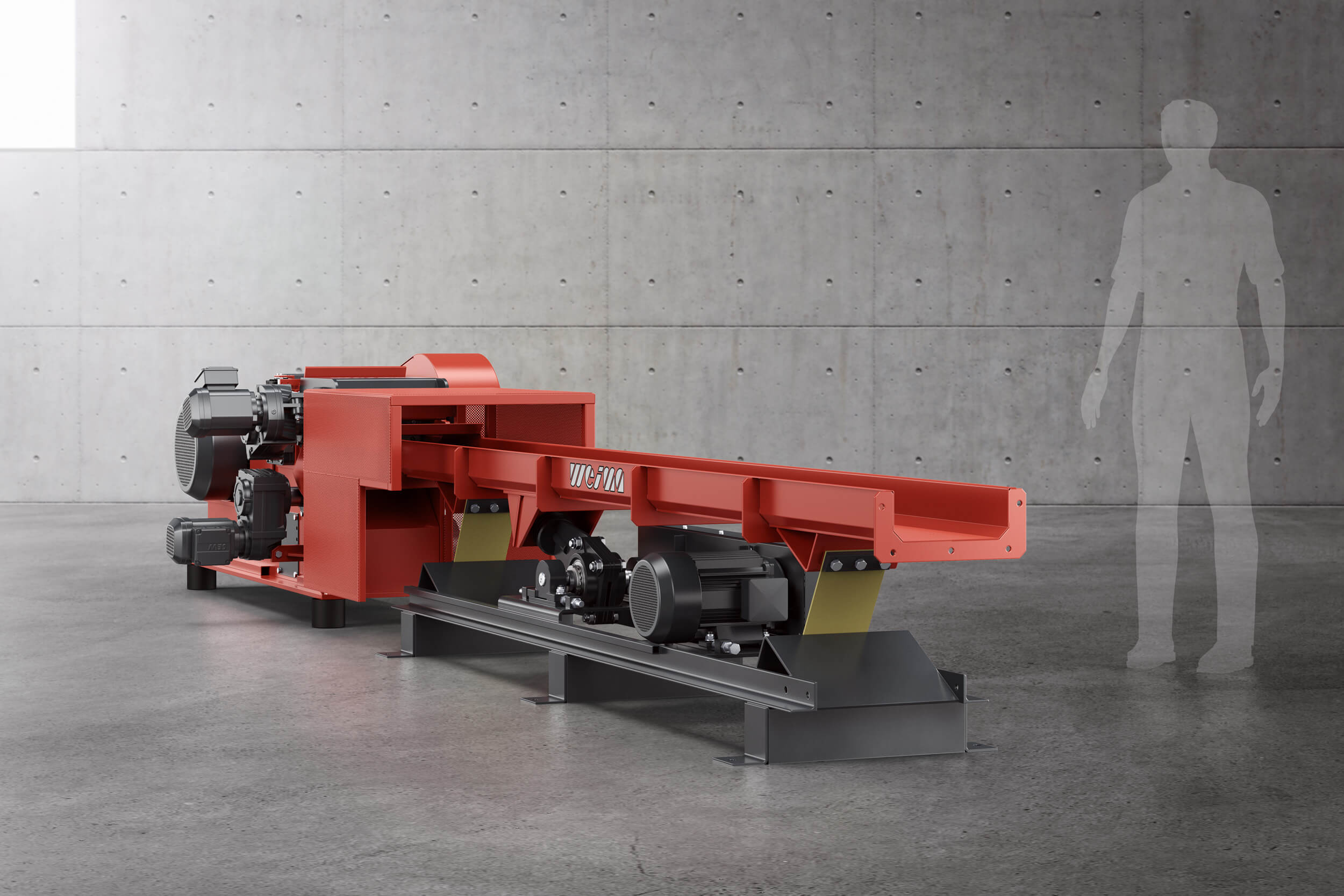

S7.20 lift-up

![orange red weima shredder in front a grey concrete wall]()

Single-shaft shredder

Explore Machine -

S7.25 lift-up

![WEIMA shredder für Kunststoffe vor grauer wand]()

Single-shaft shredder

Explore Machine -

S7.30 lift-up

![WEIMA shredder für Kunststoffe vor grauer wand]()

Single-shaft shredder

Explore Machine

Series

S5 | S7

With up to 700 mm rotor diameter for particularly demanding applications and throughputs

-

PreCut 2000

![]()

Single-shaft shredder

Explore Machine -

PreCut 2500

![]()

Single-shaft shredder

Explore Machine -

PreCut 3000

![]()

Single-shaft shredder

Explore Machine

Series

PreCut

Robust and low-maintenance pre-shredders for highest demands

-

PowerLine 1500

![]()

Single-shaft shredder

Explore Machine -

PowerLine 2000

![]()

Single-shaft shredder

Explore Machine -

PowerLine 2500

![]()

Single-shaft shredder

Explore Machine -

PowerLine 3000

![]()

Single-shaft shredder

Explore Machine

Series

PowerLine

Powerful waste shredders for highest throughputs

-

FineCut 1500

![]()

Single-shaft shredder

Explore Machine -

FineCut 2000

![]()

Single-shaft shredder

Explore Machine -

FineCut 2500

![]()

Single-shaft shredder

Explore Machine -

FineCut 3000

![]()

Single-shaft shredder

Explore Machine

Series

FineCut

Fast rotating secondary waste shredders

-

Beaver 400

![]()

Horizontal shredder

Explore Machine -

WLH 300

![Holz-Shredder]()

Horizontal shredder

Explore Machine -

WLH 400

![Holz-Shredder]()

Horizontal shredder

Explore Machine -

WLH 600

![Holz-Shredder]()

Horizontal shredder

Explore Machine -

Tiger 400 S

![]()

Horizontal shredder

Explore Machine -

Tiger 600 S

![]()

Horizontal shredder

Explore Machine -

Tiger 800 S

![]()

Horizontal shredder

Explore Machine -

Tiger 1000 S

![]()

Horizontal shredder

Explore Machine -

Tiger 1300 S

![]()

Horizontal shredder

Explore Machine -

Tiger 800 Jumbo

![]()

Horizontal shredder

Explore Machine -

Tiger 1000 Jumbo

![]()

Horizontal shredder

Explore Machine

Series

WLH

Compact horizontal grinders for long parts – ideal for automation

-

ZM 30

![]()

Four-shaft shredder

Explore Machine -

ZM 40

![]()

Four-shaft shredder

Explore Machine -

ZM 50

![]()

Four-shaft shredder

Explore Machine -

ZM 60

![]()

Four-shaft shredder

Explore Machine

Series

ZM

Low rpm and quietly rotating four-shaft shredders for aggressive infeed

-

M8.28

![Primary shredder M8.28 with two-shaft technology]()

Twin-shaft shredder

Explore Machine

Series

M8

Heavy duty pre-shredder with twin-shaft technology for extreme applications

-

WSM 260 / 500

![]()

Granulator

Explore Machine -

WSM 300 / 600

![]()

Granulator

Explore Machine -

WSM 500 / 700

![]()

Granulator

Explore Machine

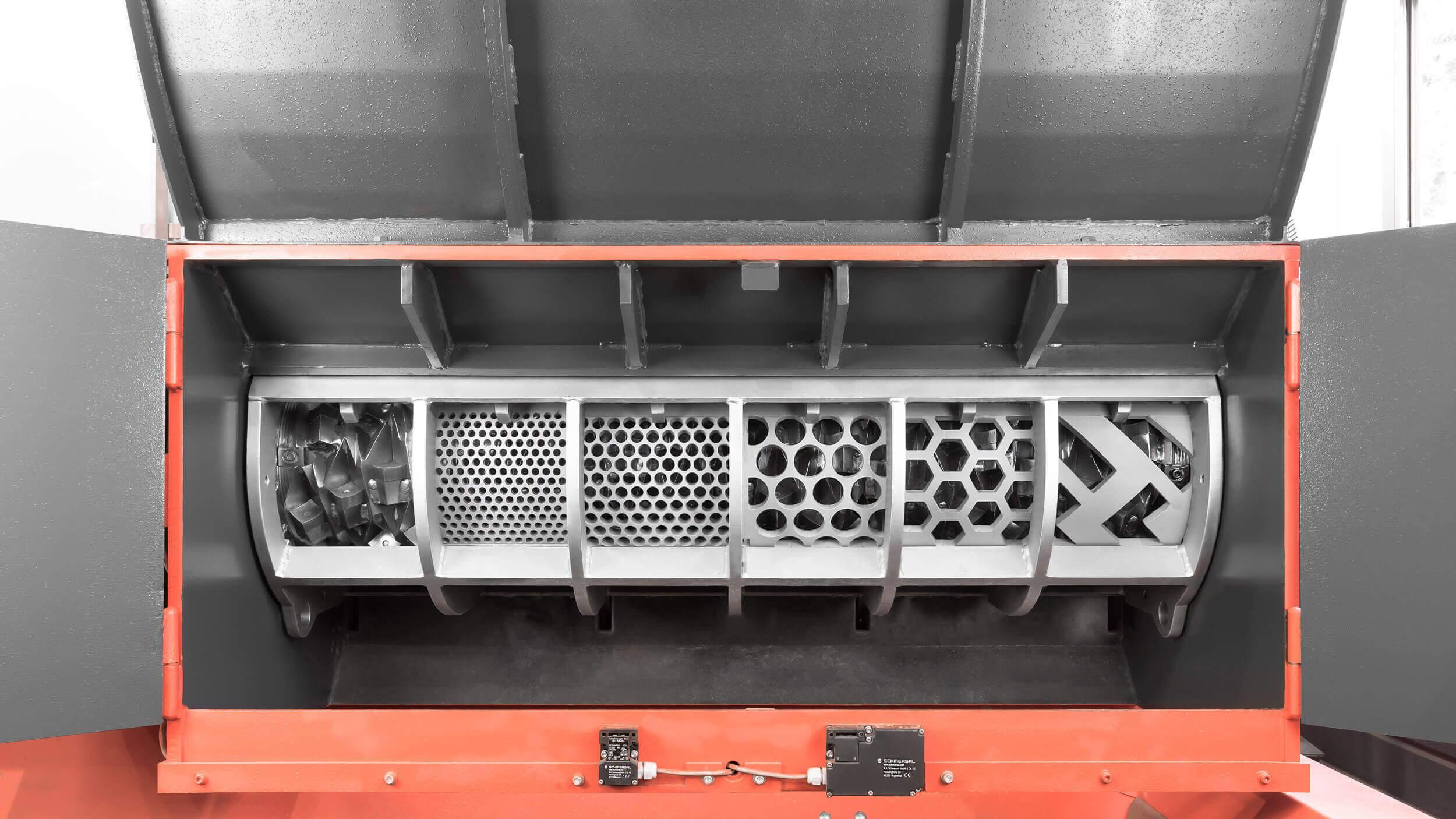

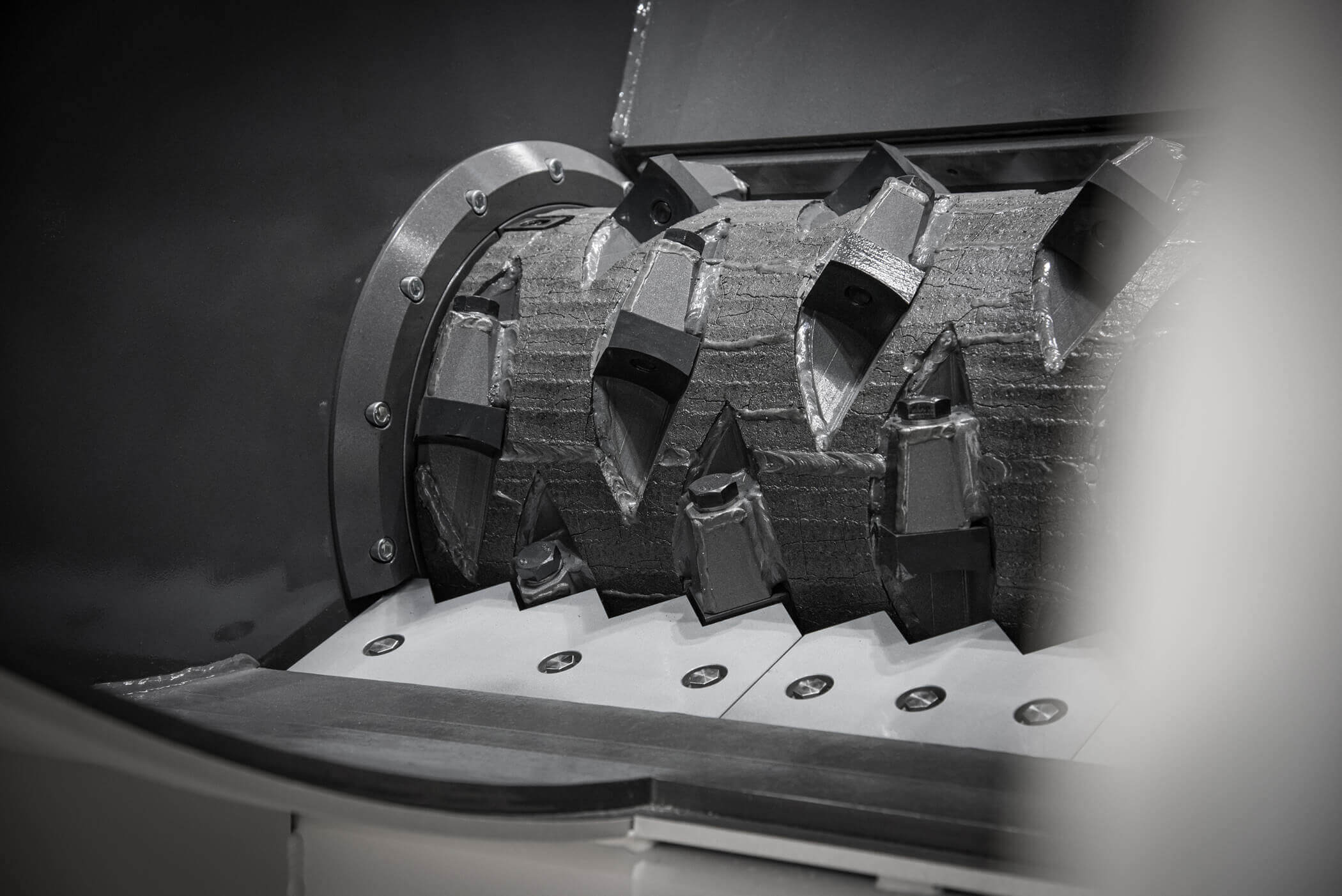

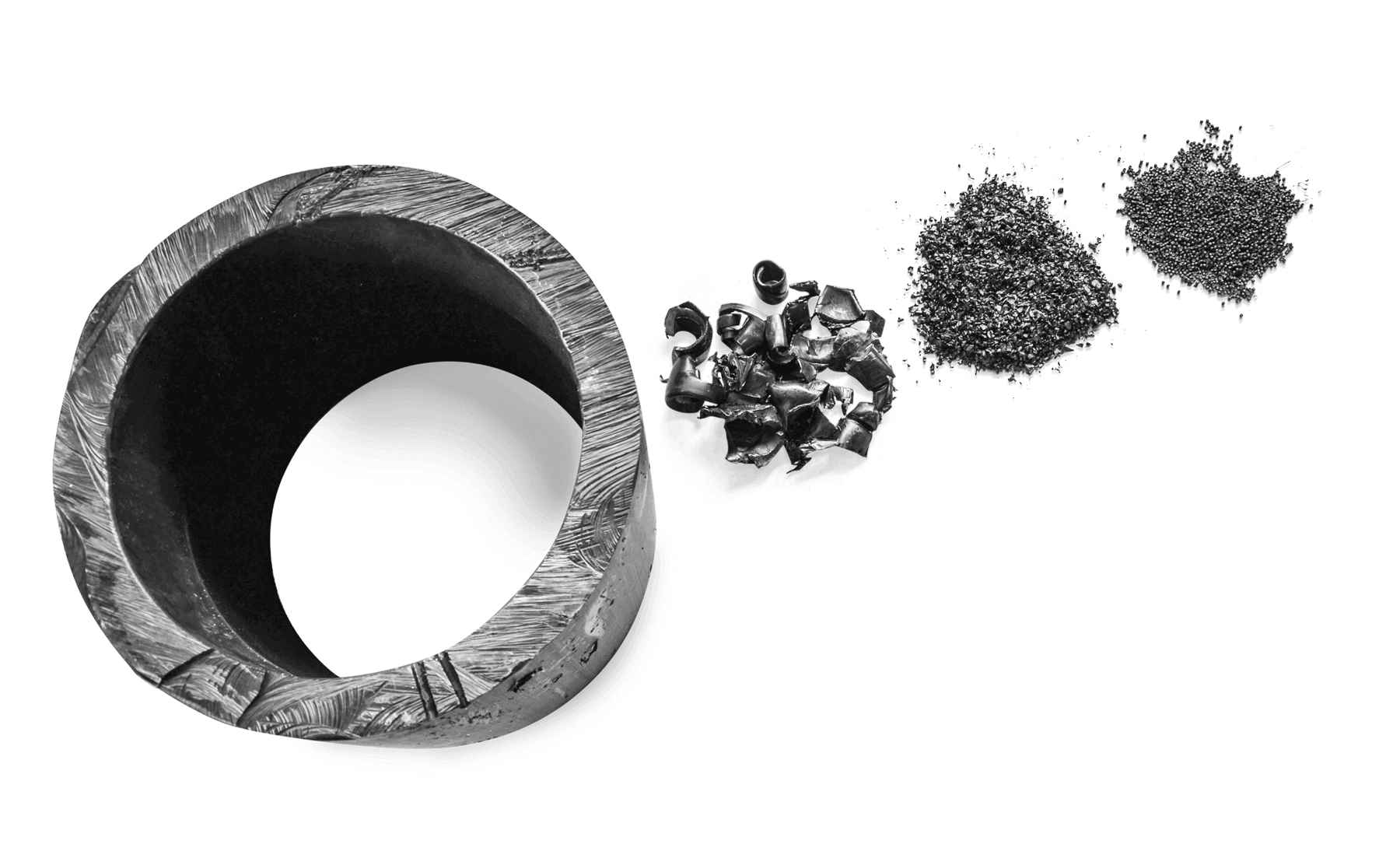

Series

WSM

High-throughput granulators for smallest particle sizes

-

WNZ 200 / 600

![]()

Granulator

Explore Machine -

WNZ 200 / 800

![]()

Granulator

Explore Machine -

WNZ 310 / 600

![]()

Granulator

Explore Machine -

WNZ 310/800

![]()

Granulator

Explore Machine

Series

WNZ

Compact and fast rotating secondary shredders for regular throughput rates

-

Woodwolf 1500 S

![]()

Breaker

Explore Machine -

Woodwolf 2000 S

![]()

Breaker

Explore Machine -

Woodwolf 3000 S

![]()

Breaker

Explore Machine

Series

Woodwolf

Proven industrial pre-crusher for primary size reduction