Metal chips recycling and metal briquetting with WEIMA

Don’t overlook the versatile advantages and reclaim opportunities that can be realized through metal briquetting.

Metal chips recycling and metal briquetting with WEIMA Metal chips recycling and metal briquetting with WEIMA Metal chips recycling and metal briquetting with WEIMA

These briquette presses are currently particularly popular.

Learn more about metal briquetting

Metal briquetting for cutting fluid reclaim and material recovery

Metal briquettes offer numerous advantages: optimized storage and more efficient transportation through volume reduction. The briquetting process for metals also enables the recovery of expensive cooling lubricants, residual oils and emulsions, which are then fed back into the cooling or lubrication circuit. The resulting metal briquettes can be smelted down directly, whereby they sink down in the melting process and thus melt with less slag formation and burn-off.

Don't waste this valuable resource!

WEIMA not only briquettes light metals such as aluminum and magnesium, but also copper, brass and bronze, as well as sawing and milling waste from steel. Even special alloys in powder form, slag compounds, battery waste or grinding sludge from the most diverse materials can be briquetted without any problems. The briquetting process for metals provides an optimal starting point for the further processing or sale of pressed metal chips.

Scrap in the best form

Briquetted metal waste has up to 90 percent less volume than loose metal chips.

Customer applications and examples

Sample materials from the metalworking industry

Advantages of briquetting

1. Direct and efficient melting down of the metal briquettes with significantly less burn-up

2. Volume reduction of up to 90% of the starting material

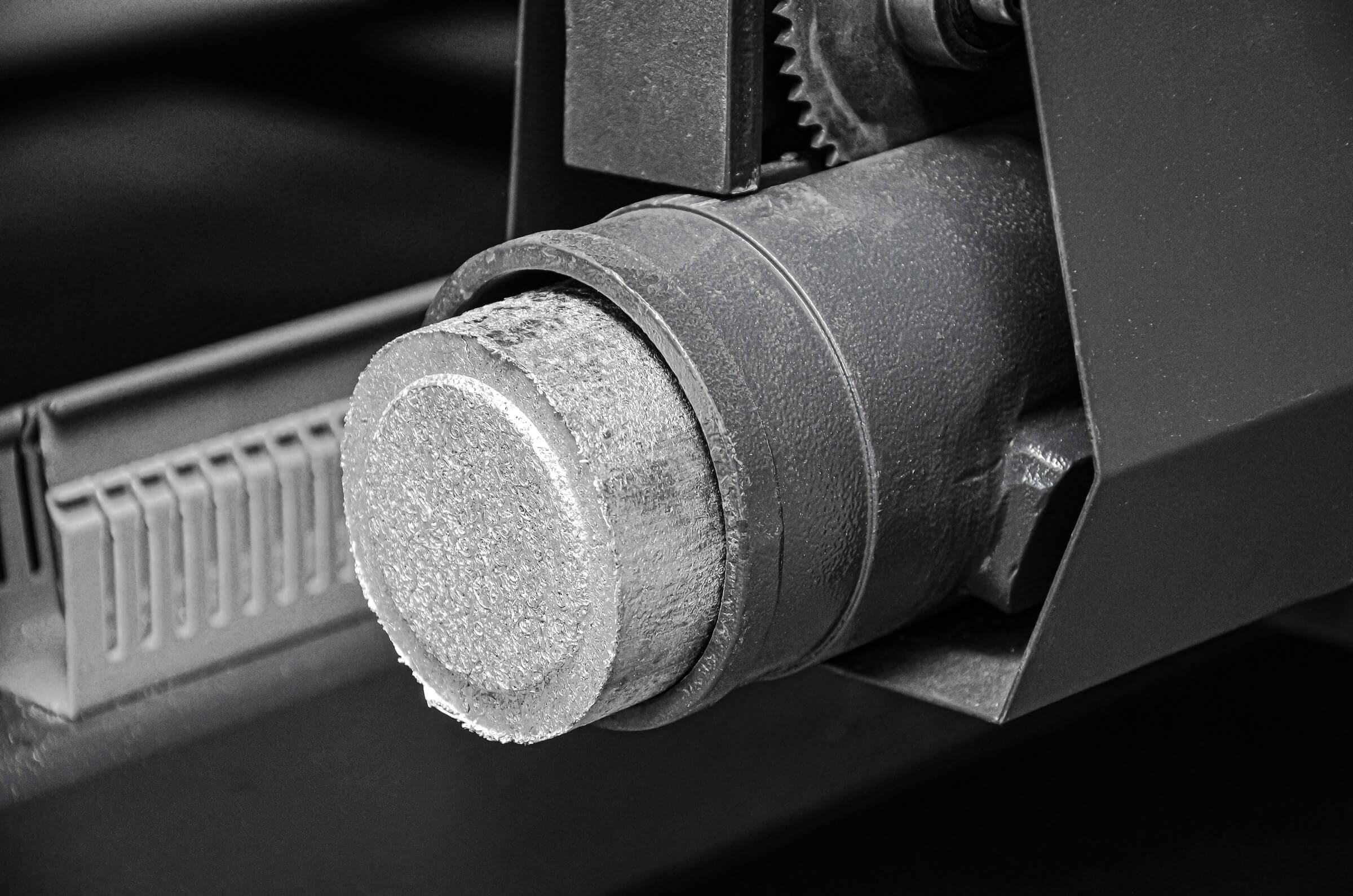

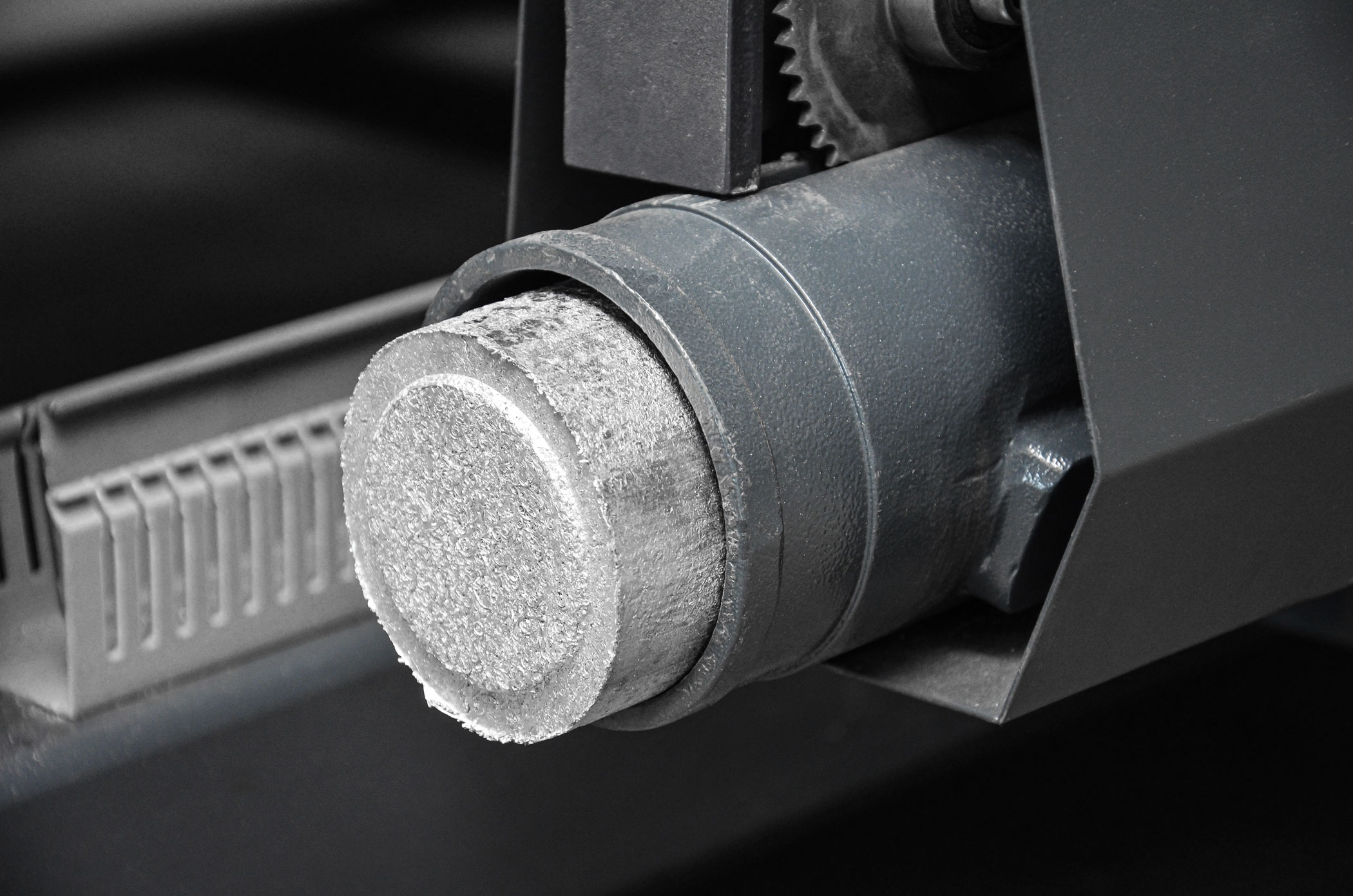

3. High pressing pressure for high briquette density

4. Better residue handling

5. Minimized disposal costs

6. Reduction of transport and storage costs

7. User-friendly design

8. Maintenance friendly

Inquire about a metal briquette press today

Request a quote

Metal recycling - WEIMA makes it possible

WEIMA briquette presses can be individually configured according to the desired throughput and intended use. The compact presses can stand alone or be installed in a production plant.

Aluminium briquette with embossing

WEIMA offers the entire performance spectrum of briquette presses for small metalworking companies with a capacity from approx. 40 kg/h up to high-performance presses for industrial companies with a capacity of up to 400 kg/h.

Steel briquettes

Shredding and briquetting of metal waste

In the metal recycling process, shredding is often the first step. Depending on the composition and shape of the metal scrap, it is sometimes necessary to shred the residual metal before briquetting. This results in a homogeneous throughput size which are ideal for further processing. Shredding and further preparatory processing steps such as cleaning of the metal chips contribute significantly to the production of higher quality metal briquettes.

The WEIMA show room is equipped with shredding and briquetting machines of all sizes and technologies. This enables us to simulate your application as realistically as possible. You have the possibility to send us your material or visit us directly in sunny South Carolina.

Request an appointment now

Light alloy briquettes

Success stories

What our customers think

What are you looking for?

Explore all WEIMA solutions