The basics of briquetting and shredding

Machine Portfolio - Shredders

Learn about the differences between our single-shaft, four-shaft shredders, granulators, and chain impactors.

Single-shaft shredders

In general, we distinguish between single-shaft shredders, four-shaft shredders and granulators. Single-shaft shredders come with a rotor (cutting system) which is equipped with special rotor Knifes. These Knives cut the material that is pushed horizontally towards the rotor by a hydraulic ram. With WEIMA’s innovative V-rotor nearly every kind of material can be shredded. The fraction size, meaning the size of the output material, is determined by a screen, mounted underneath the rotor. Depending on the application the screen hole size can vary.

Feeding single-shaft shredders can either be classically vertical (hopper) or horizontal (vibrating chute). Horizontally fed shredders (Beaver, Tiger and Leopard series) are especially suitable for a variety of linear profiles such as wood strips or bulky square timber.

Four-shaft shredders

The feeding of four-shaft shredders (ZM and ZMK series) takes place vertically via the hopper. In contrast to twin-shaft shredders, four-shaft shredders can be equipped with a screen. This leads to a homogenous fraction size. The material is powerfully torn and shredded by the talons of the cuttings discs, then pressed through the cut grooves of the clearing discs and finally discharged through a screen which is mounted underneath the cuttings discs.

Granulators

WSM granulators can be used either as a stand-alone solution or as a second-stage shredders in a two-stage process. The big hopper allows manual feeding or conveying. The highly effective V-rotor cutting technology, with double diagonal cut makes the production of a very fine grain size. By doing so, the fraction is taken by the rotor and ground at the stator knife until the material is small enough to fall through the mounted screen.

Rotor and cutting technology

WEIMA shredders can be equipped with different rotors and knives. This choice is directly related to the material to be shredded, in order to achieve the optimum result.

V rotor

WEIMA’s innovative V-rotor with cutting gap adjustment “SuperCut” enables first-class shredding results, matching the materials requirements. The effect: Homogenous fraction size, universally applicable, high throughput, low energy consumption, insusceptible to foreign material and low wear.

F rotor

For difficult to shred textile filaments and ribbons, but also for film, a rotor with special knifes and cutting technology has been designed in order to optimise the process. The F-rotor (the F is for filaments) is an evolution of the rotors of the proven WEIMA WLK series, used for shredding multi-filaments, Big Bags and film. The rotor can be provided with bolted or welded knife holders. Additionally, an extreme wear protection (Vautid) is available.

Flat knives

Smooth cutting knives are extremely resistant to disruption and are characterized by long tool life, even with aggressive materials. Ideal for breakable applications such as chipboard and also used as a mixed configuration.

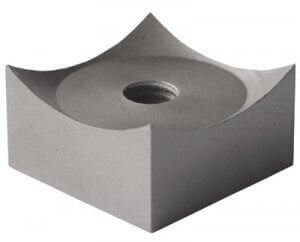

Concave knives

Concave cutters are used as standard on single-shaft shredders and universal shredders. The particularly good material feed leads to a significantly lower power requirement in the comminution of materials such as wood and hard plastics.

Extra concave knives

The use of extra-concave cutting blades significantly improves the material feed, which further optimizes the cutting behavior and prevents the material from being simply crushed. Typical example applications are filaments and films.

Carbide knives

Minimal maintenance: The use of carbide cutting blades ensures maximum service life. This knife variant is available both as a solid carbide version and with brazed carbide plates, the carbide itself is variably selectable.

Typical applications are abrasive materials such as glass fiber and sand-contaminated agricultural film.

Trapezoid knives

The WEIMA trapezoidal cutting knives offer maximum resistance to contaminants. Thanks to stable cutting edge and consistently good cut, the formation of lumps is avoided. Particularly in the case of films, the flat section is advantageous in order to obtain as much dissolved output material as possible.

CrossCut knives

The innovative CrossCut knives fit all WEIMA single-shaft shredders and single-shaft shredders from other manufacturers. The square, sawtooth rotor blades on the sides offset the previous limits of shredding technology and combine numerous advantages:

- significantly reduced energy consumption.

- quiet and bearing-friendly running behavior of the rotor.

- higher material throughput.

- even shredded material with less fines content.

- long knife life.

Adjustable counter knives

The cutting gap can be drastically reduced and adjusted perfectly with the adjustable counter knife. If the counter knife starts to wear and the cutting gap between rotor- and counter knife increases, the cutting gap can be reduced again through the adjustable counter knife this means that the counter knife lasts longer and does not to be changed as often. As a result the performance and the throughput capacity of the machine is also improved. This feature is particularly important when shredding veneer or other thin material. Most competitors do not offer this feature.

Recessed knife bolts

The knives are bolted with hexagonal bolts. These are recessed into the knife carrier. By recessing them, the heads of the bolts don’t wear. This offer lasting bolt durability and makes easy removal at the times of rotation or replacement. Knife bolts of other manufacturers others are often exposed causing excessive wear, making maintenance tasks for knife rotation or replacement difficult and time consuming. In many instances forcing the engineer to resort to using an angle grinder.

Clearing knifes

WEIMA’s clearing knifes are located very close to the rotor sealing. Such a placement ensures material is being cut on nearly the entire length of the rotor. Other manufacturers do not have such a feature. They place their clearing knifes far away from the rotor sealing so that the material cannot be cut. If this material reaches the rotor bearing, it can be damaged.

Shredder drive options

Conventional drive

The conventional drive, used for granulators or single-shaft shredders, uses a standard motor and an in-house developed gearbox regulating the rotational speed.

High-torque drive

Hydraulic drive

His hydraulic drive working in the harshest applications. Speed and torque can be adapted to the material to be shredded, without undesirable current peaks. The available drive power can be optimally applied reducing consumption by as much as 30 percent.

WEIMA WAP gearbox

WEIMA shredders are equipped with a newly developed gearbox – the WAP gearbox. Manufactured by WEIMA, it is low-wearing and ruggedised against difficult materials. The shoe-box shape of the new gearbox makes it very maintenance-friendly. By removing a single cover it is fully exposed. Moreover, the gearbox needs only four fasteners – competitors often need more than seven. The main advantage of the gearbox is the fact that is has been set up specifically for the purpose of shredding (e.g. heavy-duty designed gearwheels and shafts). Standard gearboxes are designed for constant loading which is not applicable for industrial shredders. Gearboxes for size reduction equipment are required to withstand fluctuating loads and shocks. The WEIMA WAP gearbox is design for these environments which makes it much more robust and reduces wear increasing longevity.

Shredder features

Gimbled suspension of ram cylinders

The cylinder driving the hydraulic ram is gimbled suspended. Lateral forces on the cylinder can be buffered. This leads to a longer life-time of the cylinder and the suspension. Others who don’t provide this feature are not able to absorb these shocks. The result is repetitive high wear characteristics.

Safety limit switch

The safety limit switch used for WEIMA shredders prevents damage of the rotor by foreign objects or malicious damage. If for example a hammer head is unintentionally introduced into the shredder, the switch is automatically triggered. Damage to rotor knives and counter knives can be avoided by the machine stopping automatically. Others don’t provide this protection. This can lead to catastrophic rotor, knife, counter knife or worse gearbox damage

Bolted shaft stud

The advantage of a bolted shaft stud (up to 368 mm rotor diameter) is its hardened design which leads to minimized wear caused by abrasion of bearings. The shaft studs don’t need to be replaced. Moreover, there’s no need to change the entire rotor when it has been damaged by foreign objects. It is only necessary to replace the stud, a much less expensive option.

Hydrodynamic clutch

The advantage of a hydrodynamic clutch (up from 30 kW) is smooth machine start even when the hopper is fully loaded. This avoids extreme power demand spikes avoiding excessive energy costs. Furthermore, the clutch prevents damage of the gearbox when the rotor reverses.

Offset K bearing

The closed, offset and maintenance-friendly spherical roller bearings are specially designed for plastic shredding applications and processing very dusty material. Shredded plastics can create excessive heat travelling into the rotor bearing. This effect is prevented by an offset bearing. In this case, bearings are not mounted on the machine frame directly and therefore no material reaches the bearings. Durability is much higher with offset bearings of which also demand lower maintenance than open bearings. Exchanging out K bearings is a far simpler affair while other bearings hold a shorter life span and far more difficult to replace.

Brass guides

Instead of plastic guides WEIMA use guides made of brass – the increased durability is most relevant especially when very abrasive materials (e.g. pallets) are to be shredded. In addition, ram on rolls guides can be provided. Others don’t offer this feature and rely on exchanging guides on a more regular basis increasing cost of maintenance and production downtime.

Rotor protection against abrasive materials

For shredding contaminated or abrasive materials (e.g. sand-contaminated agriculture film or glass-fibre materials) WEIMA offers a number of anti-wear protections. As the solid steel rotor is exposed to most wear caused through friction it should be the main focus to protect this costly machine part. For rotor protection WEIMA offers Creusabro 4500 or Vautid which both last a very long time due their extremely tough quality. Both forms of protection last much longer than the popular Hardox protect.

Lifting Screen basket

WEIMA single-shaft shredders offer a movable screen basket which is available in manual or hydraulic. This enables our customers to maintain and to clean the machines very quickly and cost-effectively. This feature is especially important when shredding abrasive materials which results in an increased wear characteristics. A quick and easy turn or exchange of knives is possible with this feature as it offers extremely easy access to the rotor- and counter knives. In addition, the screen can be exchanged within a few minutes in order to reach a different fraction size. The screen is divided into segments which allow a single employee to change the screen inserts manually. The weight of one screen insert is approx. 12 kg.

Ram comb / Ram comb plate

The hydraulic rams of the WEIMA shredders can be equipped with a so-called ram-comb for wood shredding or with a ram-comb plate for the shredding of plastics. This feature keeps the material in front of the pusher and avoids that the material escapes from the rotor. The ram comb / ram comb plate leads to an increased throughput capacity and prevents material jumping out of the machine. The ram comb covers only the upper part of the pusher front whereas the ram comb plate covers the complete front of the pusher.

Pipespacer / Logspacer

Shredding of massive logs, bales, pipes or other hollow objects which are not made out of flexible material and which has a bigger diameter than the rotor diameter we recommend a WEIMA Pipespacer / Balespacer / Logspacer. The Pipespacer makes sure that the material is not being pressed against the wall of the shredder but is in constant contact with the rotor until shredded.

Anti vibration foundation

The machine stands on anti vibration foundation. Under the legs of the frame rubber feet are installed to absorb the vibrations caused by the machine. The frame itself can be adapted to the needs of our customers.

Hydraulic oil cooling for 3 shift operation

The fast action of the ram requires a hydraulic oil cooling unit in order to avoid damage caused by heating of the oil. This equipment is a separate unit which is mounted in a protected box. Result is a three shift working without breakage, a hydraulic unit which can be maintained easily and placed in a protected area.

Discharge opening for conveyor belt

A huge undersupport under the machine wich a wide opening guarantees to place almost all different types of conveyor belts underneath the machine. As result by using a wide belt almost all material is collected and transported by the belt, no mess under the machine.

Central lubrication system

Delicate items as bearings and cylinder need to be greased regularly, if this is not done the risk to damage these parts is extremely high, therefore WEIMA offers a central lubriction system which greases them regularly and automatically.

Machine Portfolio - briquette presses

Clamp press

The material is added manually or by means of a filter system in a funnel. A motor driven agitator continuously fills the channel of the discharge screw. The screw transports the material into the supercharger. An automatic briquette length control regulates the screw rotation time and determines the amount of material to be pressed in order to keep the length of the briquette constant. Subsequently, a hydraulic filling slide pushes the material into the actual pressing space. A likewise hydraulically controlled pressing tongs, in conjunction with the specially hardened pressing cylinder, ensure the excellent briquette quality.

The pressing is done without binder, the maximum material moisture should not exceed 18 percent. The material-dependent performance of the Briquetting Press Type C 150 is between 30 and 50 kg / h.

Matrix press

When filling is completed and the rear of the press cylinder is reached, the filling cylinder compresses the filled material to the limits of the filling chamber (corresponds to the height of the press ram). When the filling cylinder reaches this waypoint, the die is moved over the sliding cylinder so that the new briquette is formed in the empty die. The briquette is ejected from the die on the respective side via the ejectors arranged on the left and right and fed to the stack. When the pressing cylinder reaches the briquette length (alternatively the pressing pressure), the cylinder is stopped, the hydraulic pressure is decompressed and the pressing cylinder moves back.

During this process, after emptying the storage container, a new batch is prepared: When ancestor of the press cylinder is reached after reaching a defined waypoint, the filling cylinder and the material for the next cycle dropped.

After reaching the upper end point of the filling cylinder, a new cycle is started with the precompression.

Briquette press features

Universal-mounted screw conveyor

Prevents damages caused through lateral forces. For example if a big piece of solid metal gets by mistake into the screw channel, the screw will not be damaged – due to the fact that it is mounted by a cardanic joint the screw is flexible.

Gimbal-mounted screw conveyor

Proximity switch

The cylinders are no longer mechanically controlled but electrically by a proximity switch at the top front and top end position which helps to get more precise movements. Some competitors use still mechanical ones or pressure switches to control the movement of the piston. This is a system that is far more often failing and is not as exact and can therefore lead to blockages of the cylinder. Our electrical limit switches are completely maintenance free and no wear occurs. For the briquetting of lead the switches are lying outside the cylinder.

Cushioned cylinders

The cylinders are no longer mechanically controlled but electrically by a proximity switch at the top front and top end position which helps to get more precise movements. Some competitors use still mechanical ones or pressure switches to control the movement of the piston. This is a system that is far more often failing and is not as exact and can therefore lead to blockages of the cylinder. Our electrical limit switches are completely maintenance free and no wear occurs. The main pressing cylinder is dampened hydraulically whereas the other cylinders are dampened by valves.

Precise measuring system

A modern measuring system is indicating exactly the position of the filling cylinder, thanks to that each millimetre can be controlled and visualized at the touch screen

Hydraulic tank

The bigger the tank the longer is the working time without heating up of the oil. This means the machine can work longer due to the bigger hydraulic tank. Competitiors mostly have a smaller tank and cannot work so long during a day without oil cooling. In addition WEIMA offers a big and robust pressing unit. This results in high briquette quality and in low wear.

Hardened pressing chamber

The pressing chamber mould is made out of hardened tool steel and can be changed at any time very easily and at a low cost. Wear is minimized due to the hardened surface of the pressing chamber mould. In competitive systems it is necessary to change the whole press block of the machine. This is the heart of the machine and therefore the cost is very high.

Briquette length control

The briquette can be regulated in length, (from half of the diameter to 1,5times of the diameter). This helps to reach always the same briquette length - even with different materials.