Label presses for draining and compressing

With hydraulic WEIMA presses, plastic and aluminum labels or caps of glass and plastic bottles are not only drained by up to 70%, but also reduced in volume.

Especially bottling plants and plastic recyclers can find a sustainable solution for the cost-effective disposal of labels and label waste from their own production or post-consumer waste.

Label presses for draining and compressing Label presses for draining and compressing Label presses for draining and compressing

These drainage presses are currently particularly popular.

Lots of beverage labels, caps and bottle labels? Drain, compress and professionally dispose of them now.

Learn more about the sustainable use of old labels.

WEIMA label presses stand for robust, durable technology and maintenance-friendly operation. They not only ensure clean production halls, but also relieve the burden on intralogistics. Reduce your disposal costs and increase your container service life – with WEIMA drainage machines.

In the following gallery you will find examples of applications. These include labels, capsules for closing and labelling beer bottles, champagne bottles made of glass, as well as soft drink and juice bottles made of PET plastic.

Customer applications and examples

From the industry

Inquire about a label press today

Request a quote

Many labels – one WEIMA press

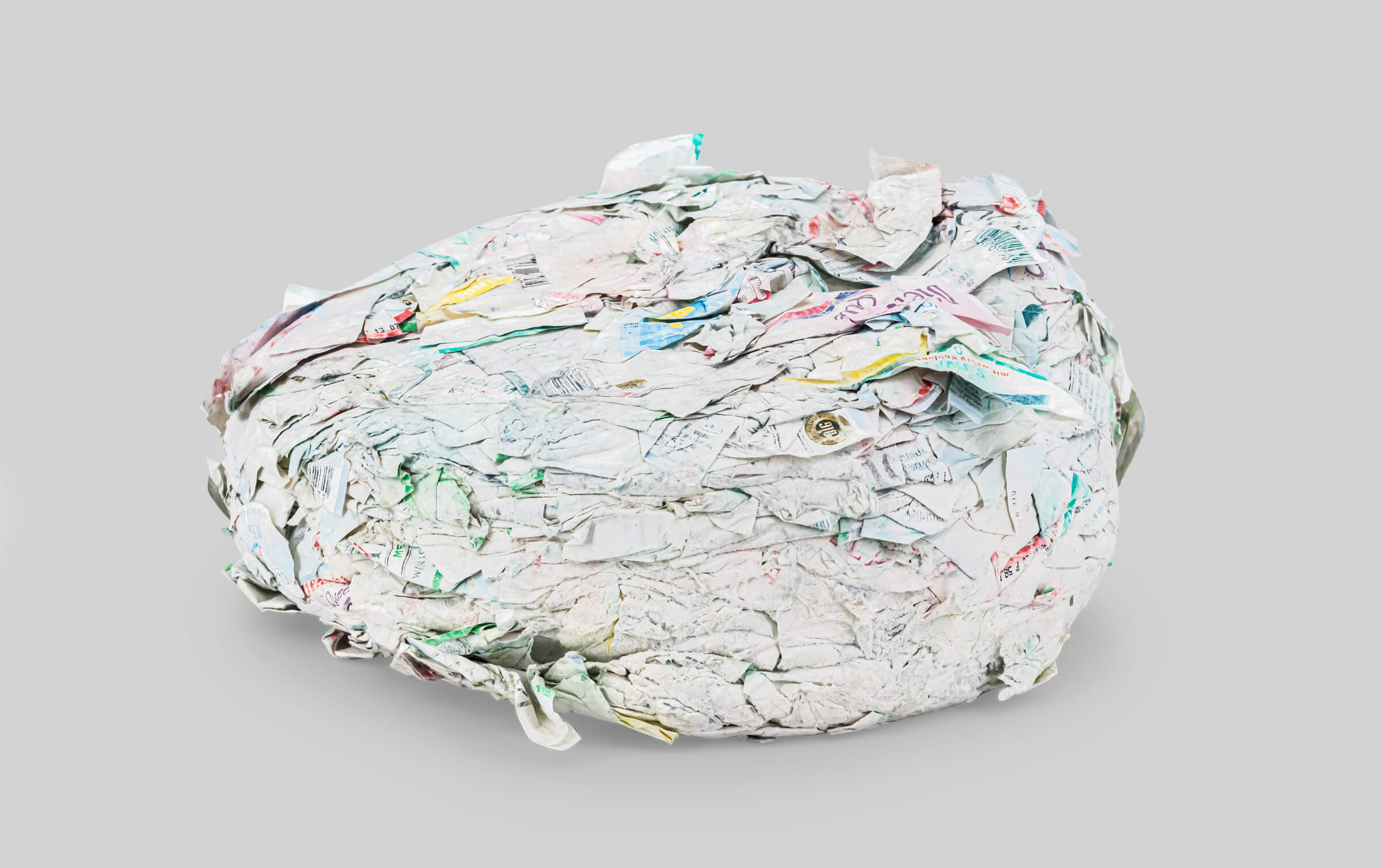

Labels on glass and plastic bottles are available in numerous sizes, shapes, colors and materials. But one thing unites them: WEIMA machines compress them into discs.

It doesn't matter whether you want to press body labels, breast labels, metal or PVC capsules, strip labels or back labels made of paper, PE film or aluminum foil. We have the right drainage solution for every beverage label.

Variety of labels on glas bottles

Did you know?

"With WEIMA label presses, the volume of labels can be reduced to up to 30%."

Tobias Flaig

Chief Technology Officer | Compressing at WEIMA

Pressing of golden closing caps

The old-established Rothaus brewery also relies on WEIMA compaction technology. With an individual machine solution, used metal foil capsules made of aluminum are not simply disposed of, but compressed into compact discs.

Economic disposal of old labels

By draining and compressing the labels, the weight and volume can be significantly reduced. This also reduces disposal costs. In addition, valuable lye can be recovered.

Automation in breweries

Advantages of using the WEIMA label presses

1. High compaction and draining of the products in one operation

2. Destruction of the deposit seal

3. Saving expensive disposal costs

4. Maximum recovery of the material

5. Extracted lye can be safely removed and reintegrated

6. Volume reduction of labels by up to 70 %

7. Dewatering degree to approx. 30 % residual moisture

8. Low maintenance and low-wear machine technology

9. Resistant against foreign materials

10. Flexible use and integration into existing systems

11. The machine is delivered pre-installed and ready to plug in

12. Individual adjustments to customer requirements

See for yourself

We are happy to offer you the possibility to simulate your application in our facilities as realistically as possible. You have the possibility to send us your material or visit us directly in Abstatt.

Ask for an appointment now

Alternatively you can send us material for testing. Click here for the form.

Wet labels in the press process

Special offer

Arrange a free material trial today.

Free material trial