Paper waste briquetting and recycling

WEIMA offers a diverse range of solutions for paper briquetting, including files, confidential documents, banknotes, labels, filter dust, and shredded cardboard. Our highly specialized paper briquetting presses efficiently transform these materials into compact briquettes that can be easily stored, transported, and recycled.

Paper waste briquetting and recycling Paper waste briquetting and recycling Paper waste briquetting and recycling

These briquette presses are currently particularly popular.

Learn more about paper and paper dust briquetting

Clean and safe

Our briquetting presses ensure operational safety and protect your employees' health, as briquetted paper dust reduces the risk of explosion and dust emissions.

Whether in inhouse recycling of production waste in a production plant or as a stand-alone solution, with a WEIMA briquette press you can solve your space, cost or safety problems simply and quickly.

Customer applications and examples

Examples from the paper industry

Inquire about a paper briquette press today

Request a quote

Did you know?

In Europe, more than 70 percent of waste paper is recycled.

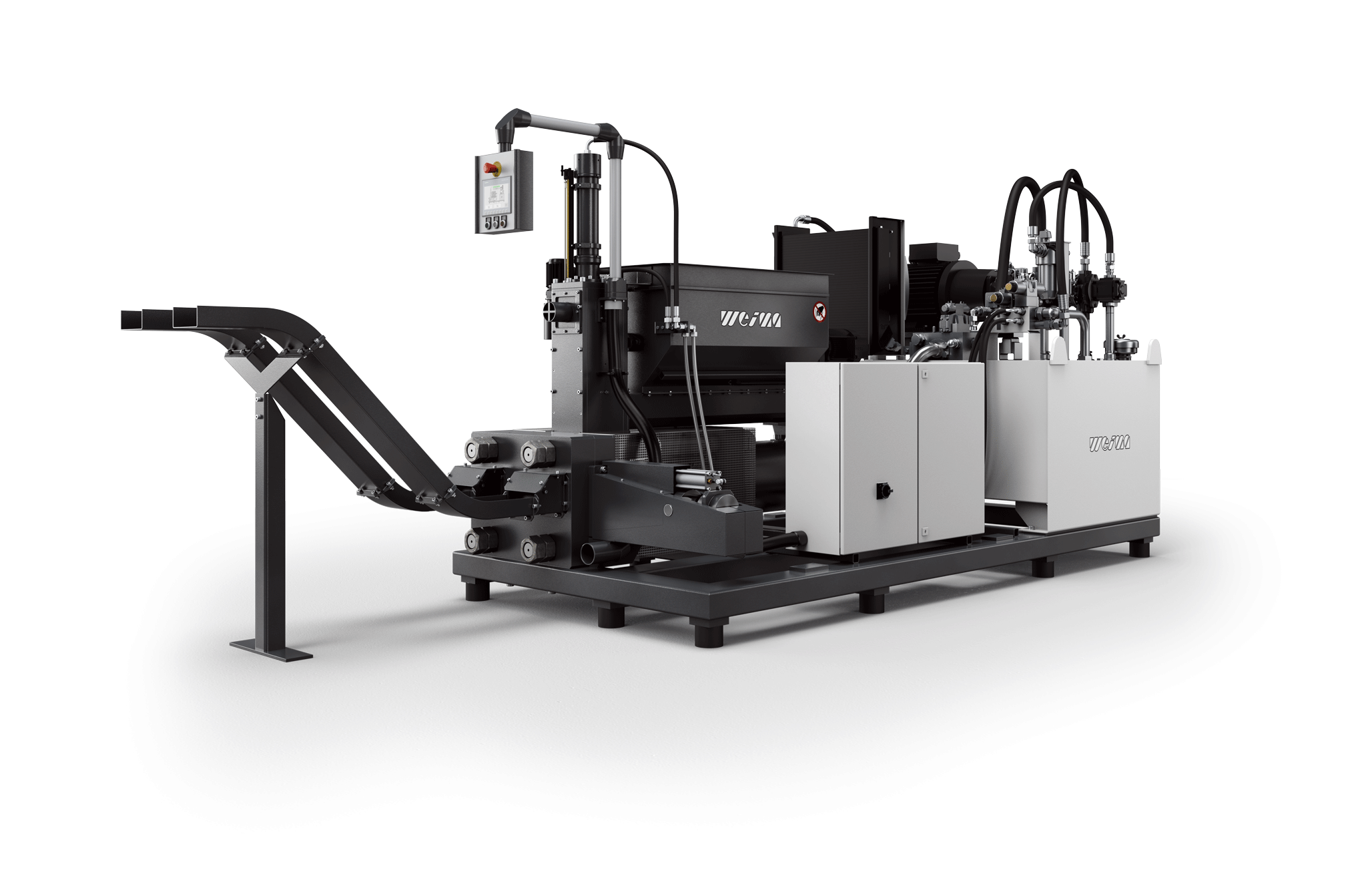

WEIMA C 140 briquette press

Advantages through briquetting

1. Volume reduction of up to 90 % of the starting material

2. Reduction of dust emission

3. High pressing pressure for high briquette density

4. Reduction of fire load

5. Better residue handling

6. Minimized disposal costs

7. Reduction of transport and storage costs

8. User-friendly design

9. High ease of maintenance

Minimize risk of explosion through briquetting

Paper dust is an enormous health and safety risk in paper processing companies. It is not only harmful to your employees, but also poses a considerable risk of explosion. In combination with a filtering extraction system, a WEIMA briquette press can help here. You can then use the compacted paper dust to generate heating energy or sell it at a profit.

Paper dust briquettes

See for yourself

The WEIMA show room is equipped with shredding and briquetting machines of all sizes and technologies. This enables us to simulate your application as realistically as possible. You have the possibility to send us your material or visit us directly in Ilsfeld.

Request an appointment now

Alternatively you can send us material for testing. Click here for the form.

Briquette production from paper filter dust

Success stories

What our customers think

What are you looking for?

Explore all WEIMA solutions

Special offer

Arrange a free press trial today.

Free press trial