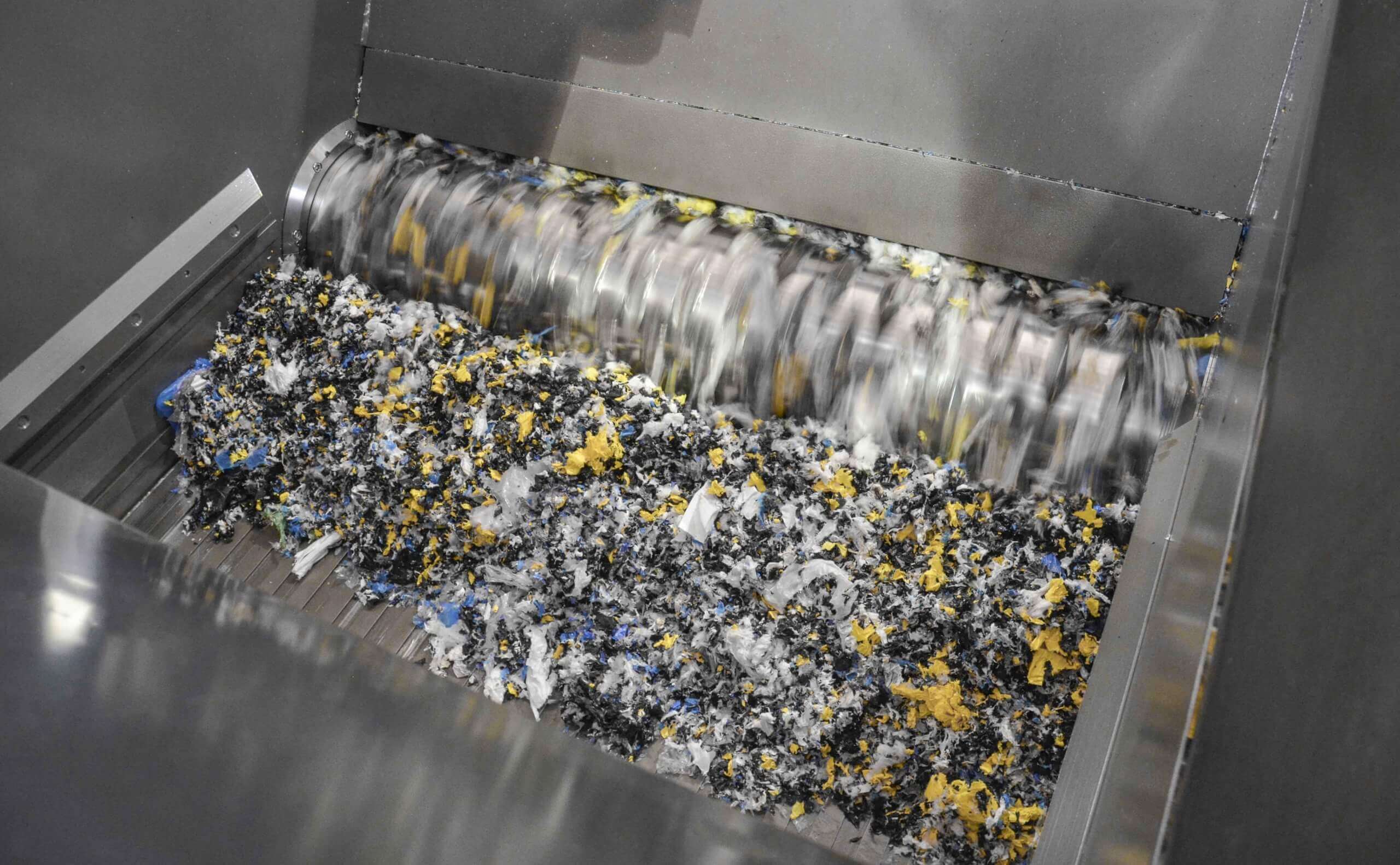

In-house Recycling and Post Consumer Plastics Shredding

Plastic is a versatile material. Its properties range from tough polymer structures to highly rigid high-tech products. Efficient shredding requires a great deal of experience and know-how.

With many thousands of plastic shredders delivered, there are hardly any applications that we have not already implemented. These include classic items such as start-up lumps, crates, pallets, pipes, containers, moulded parts and post-consumer waste such as PET bottles or packaging. But also particularly tear-resistant materials such as rubber, fibers and films, aramid, Kevlar or carbon.

In-house Recycling and Post Consumer Plastics Shredding In-house Recycling and Post Consumer Plastics Shredding In-house Recycling and Post Consumer Plastics Shredding

These shredders are currently particularly popular.

Learn more about plastics and plastic recycling

When waste becomes raw material

The Circular Economy starts with us

WEIMA plastic shredders are extremely flexible and offer different rotor types, rotor geometries and cutting tools, whereby they can shred a wide range of thermoplastics such as PE, PP, PVC, PS, PU and PET, as well as various thermosets and elastomers.

Even large-volume hollow bodies, long pipes and profiles, massive start-up lumps and other production waste, as well as PET bottles, textile fibers, foils, insulating materials, floor coverings, crates and containers master industrial WEIMA shredders effortlessly thanks to 40 years of experience in the plastics industry.

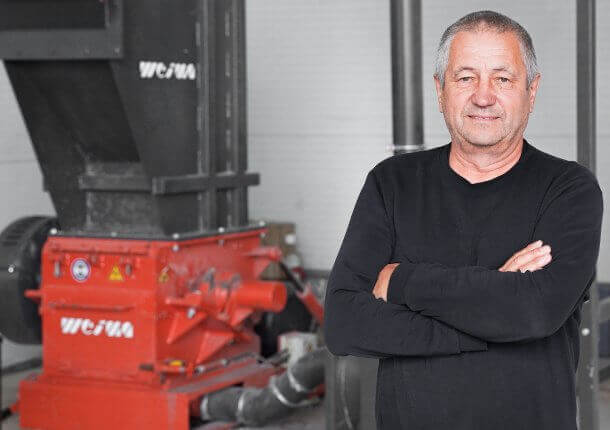

"With the high volumes of plastic waste in the world, sustainable disposal concepts are particularly needed. And shredding is the basis for this."

Gunter Schippers

Business Development | Plastics at WEIMA

PE lumps shredding with a WEIMA S7.20 shredder @Remondis Staffanstorp, Sweden

A WEIMA S7.20 single-shaft shredder shreds large and heavy PE lumps at a recycling plant of Remondis in Staffanstorp, Sweden.

Customer applications and examples

From the plastic industry

In-house recycling and post industrial plastics processing

as part of the Circular Economy

Direct return to the production line

Plastic waste generated during production is becoming increasingly valuable. As a secondary raw material, it can be returned directly to the production cycle. The first step in this process is the shredding of production waste such as start-up lumps or reject parts. WEIMA works closely with customers in order to find a suitable solution for the most diverse plastics. This way we ensure that even materials that are difficult to process are shredded into high-quality regrind.

Inquire about a plastics shredder today

Request a quote

In-house recycling saves money and protects the environment

With the right technologies, production waste can be reprocessed into new raw material. Thus you save high raw material costs, reduce long delivery times, avoid expensive disposal in external recycling plants and avoid the use of primary resources in the long term.

In-house recycling of plastic fibers

Shredding of PP flowerpots and post-consumer waste using 4 WEIMA Shredders at Aufderhaar Recycling

Take a behind-the-scenes look at Aufderhaar Kunststof Recycling from the Netherlands and their plastic recycling. Explore their upgraded production lines, featuring 4 powerful WEIMA shredders, that enable them to shred and recycle post-consumer waste and PP flowerpots.

Did you know?

Approximately 40% of the end consumer plastic waste is recycled in Germany.

Source: PlasticsEurope Germany

Post-Consumer Plastic Recycling

Post-consumer waste means plastic waste from private use. This includes packaging such as yoghurt pots, PET bottles, bags, films, containers, tubes as well as toys, labels, fibers and textiles. Due to the increase in global consumption, the amount of plastic waste is also increasing. Instead of disposing of it in our oceans or landfills, WEIMA shredders contribute to the promotion of alternative solutions. Together with our partners we develop single or multi-stage processing concepts in order to optimize the plastic lifecycle in the long term.

Shredding dirty agricultural stretch film (LLDPE) with a WEIMA PreCut 3000 shredder

A WEIMA PreCut 3000 single-shaft shredder with hydraulic drive shreds post-agricultural stretch film (LLDPE) for further recycling processing.

Why we recommend a shredder in front of a granulator

Large granulators with high drive powers have traditionally been utilized for the single-stage reduction of large pipes or voluminous plastic products, resulting in significant drawbacks such as high investment costs, noise emissions, frequent blade replacements, and elevated energy and labor expenses. In contrast, WEIMA's two-stage system, comprising a universal shredder and secondary granulator, offers an economical solution for processing start-up lumps, sprues, scrap parts, foils, cables, pipes, and various other materials in plastics processing plants. This versatile two-stage shredding system caters to a wide range of applications within the industry while addressing the challenges associated with traditional single-stage granulation methods.

Why we recommend a shredder in front of a plastic recycling extruder

In the realm of plastic recycling, both single-stage and two-stage size reduction systems are standard procedures before material enters an extruder. This approach offers multifaceted benefits beyond enhancing the overall capacity of the recycling line. By incorporating a shredder, wear and power consumption of the extruder are minimized, while operators gain increased flexibility in handling input materials. This flexibility enables smooth transitions between processing lumps, plastic films, or fibers, thereby optimizing the recycling process.

Fishing nets (ghost nets) shredding with a WEIMA WLK 1500 at Yangil Enpla, Korea

At Yangil Enpla in Incheon, Korea, a WEIMA WLK 1500 single-shaft shredder is used to shred fishing nets and other fibers for recycling and the production of regranulate.

Recycling or upcycling? It' s in your hand

Both concepts have the same goal: to extend the plastic life cycle. In recycling, plastic waste is usually shredded and transformed into regranulate by extrusion, e.g. to produce new PET bottles from old PET bottles. In upcycling, on the other hand, one tries to give supposedly useless plastics a new, higher-quality sense, either alone or in combination with others, e.g. bags made of packaging strings.

Plastic recycling

Shredding plastic purge with a WEIMA S5.18 lift-up @ Plastic Recycling Inc. South Carolina

A WEIMA S5.18 lift-up single-shaft shredder shreds plastic purge at Plastic Recycling Inc. in South Carolina.

What is Design for Recycling?

In order to ensure the recyclability of plastic products, disposal or recycling must be considered even before production begins. The term Design for Recycling (D4R), or recycling-friendly design, refers to the holistic conception and design of products that can be optimally returned to the recycling loop after their use. In this context, plastics in products should be combined in such a way that a clear separation of the different types is possible at the end of their life. This is the only way to keep waste streams pure and ensure their recyclability and thus their reuse as secondary raw materials.

For example, a German cleaning product manufacturer fills detergents in environmentally friendly refill bags. These are made of 100 percent polyethylene (PE) and contain neither adhesives nor bonding agents. The printed band can be separated from the packaging, making the bag 100 percent recyclable. Another feature is that the packaging is made entirely from recycled plastic.

See for yourself

The WEIMA show room is equipped with shredding and briquetting machines of all sizes and technologies. This enables us to simulate your application as realistically as possible. You have the possibility to send us your material or visit us directly in Ilsfeld. From our gallery you have the best view directly into the cutting chamber. So you can observe the shredding process live.

Request an appointment now

Alternatively you can send us material for testing.

Click here for the form.

Shredder in the WEIMA showroom

HDPE Pipe shredding with a WEIMA PowerLine 2500 @ Remondis Röstånga, Sweden

A WEIMA PowerLine 2500 single-shaft shredder shreds different types of HDPE pipes at a recycling plant of Remondis in Röstånga, Sweden.

Success stories

What our customers think

What are you looking for?

Explore all WEIMA solutions

Special offer

Arrange a free material trial today.

Free material trial