Shredding and recycling HDPE pipes

Information on the processing of plastic pipes

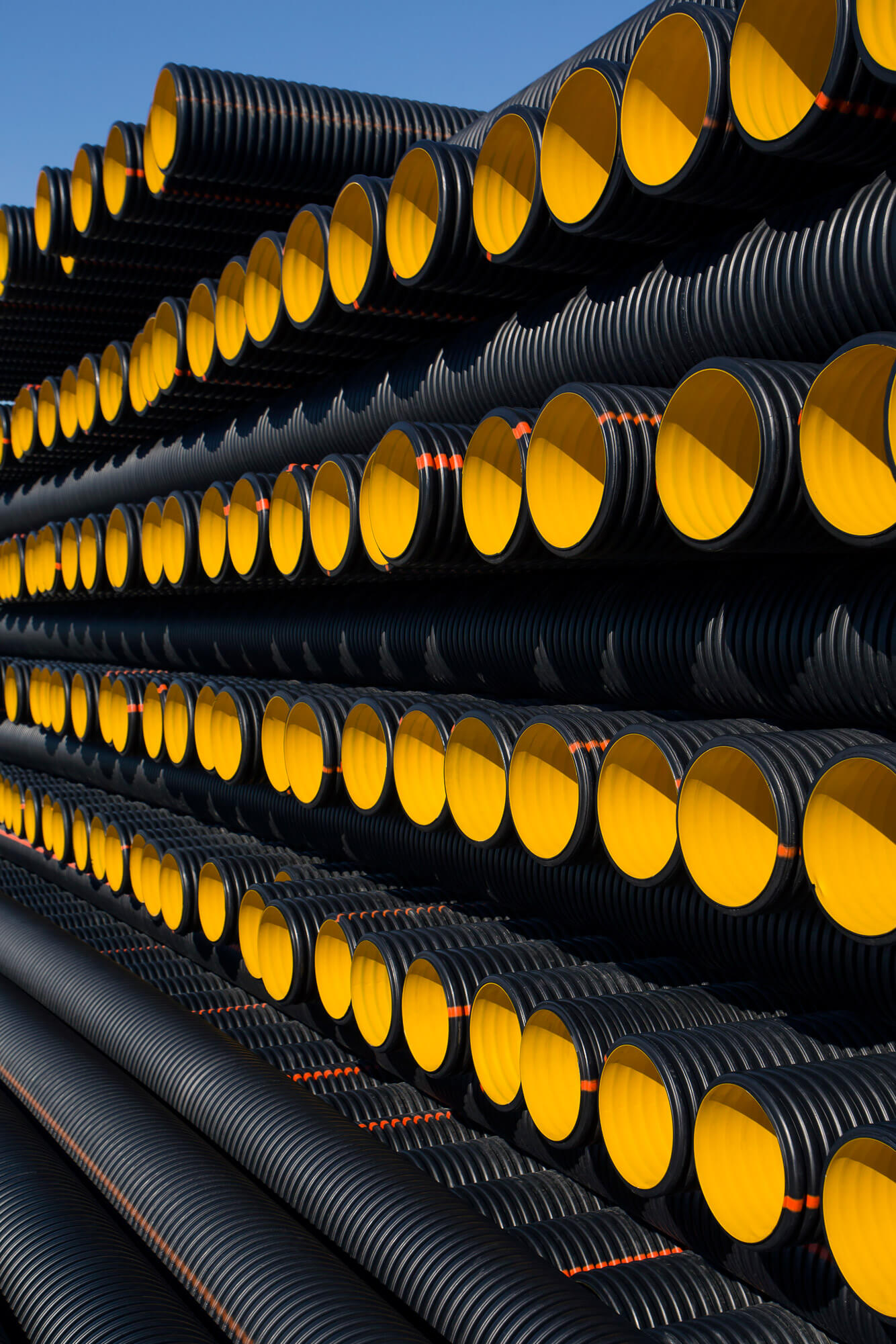

For 75+ years, it has been impossible to imagine industrial, public and private applications without plastic pipes. Concealed and usually laid underground, they transport huge quantities of resources every day - for example, wastewater and drinking water for sanitary systems, households, agriculture, and municipal sewage treatment plants. Or gas for heating systems. Plastic pipes are also regularly used as cable protection.

In particular, plastic pipes made of HDPE (high-density polyethylene) are considered to be especially resistant and flexible in use, which is why they are available in a wide variety of diameters and shapes. As with all goods and products, however, the question of proper disposal also arises at the end of their service life. In addition, the production of HDPE pipes regularly generates production waste, for example during extrusion. The good news is that this plastic is ideally suited for in-house recycling and must be shredded in the first step. Here, WEIMA can draw on decades of experience in pipe shredding.

WEIMA shredder S7.30 lift-up shreds 2.5 m diameter pipelines

HDPE plastic pipes – production and characteristics

High density polyethylene, or HDPE for short, is ideal for use as pipes due to its thermoplastic material properties. It withstands comparatively high pressures with low weight, is flexible and very resistant to corrosion. Unlike pipes made of metal, polyethylene pipes are less resistant to temperature. Under normal use, HDPE plastic pipes can be used for several decades, even underground.

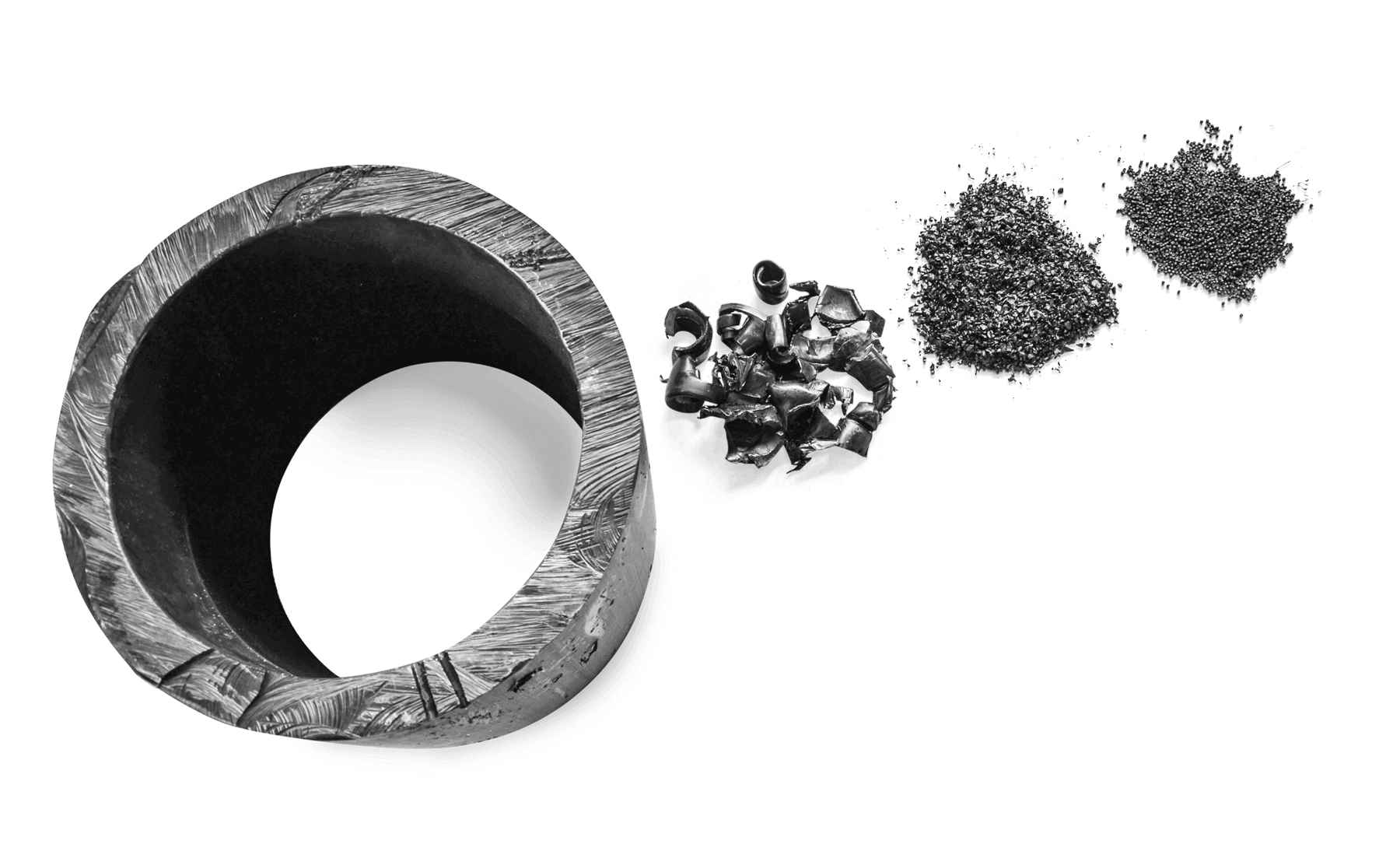

Continuous extrusion is used for the production of HDPE pipes. The granulate obtained by shredding is usually fed loosely to a single-screw or twin-screw extruder and melted. The molded plastic is then created under uniform pressure. The endless pipe produced can be cut to length as required.

HDPE Pipe shredding with a WEIMA PowerLine 2500 @ Remondis Röstånga, Sweden

A WEIMA PowerLine 2500 single-shaft shredder shreds different types of HDPE pipes at a recycling plant of Remondis in Röstånga, Sweden

Where do HDPE pipe waste and old pipes accumulate?

Plastic pipes are rightly described as one of the main lifelines of our modern infrastructure. Without them, little would work in energy supply, logistics or communications. The demand for HDPE pipes for replacement and new installation is correspondingly huge. Companies and WEIMA customers such as PIPELIFE, UPONOR or NEPROPLAST have recognized this potential and are among the leading pipe producers with numerous international locations. However, the more pipe material is produced, the higher the scrap tends to be, as well as the proportion of old pipes. Fortunately, both waste materials are recyclable, so that the plastic can be kept in the resource cycle for as long as possible.

In the extrusion process in particular, HDPE plastic waste is regularly produced during startup and run-in of the systems – namely plastic lumps, also known as purgings. In addition, produced pipe segments or pipe spools may not meet the manufacturer's quality requirements and therefore have to be recycled in-house.

Truly versatile. WEIMA shreds pipes made of PE, PP, PVC and more

The plastic polyethylene can be produced in different density grades. There is PE-LD with low density, PE-MD with medium density and PE-HD, i.e. HDPE, with high density. In addition to PE, WEIMA also shreds other thermoplastics such as PP or PVC. They are characterized by their formability when heat energy is applied and can therefore be welded for joints. The shredding of thermoplastic waste or production scrap to recycling granulate is also possible in an energy-saving way. This saves fossil oils during new plastic production.

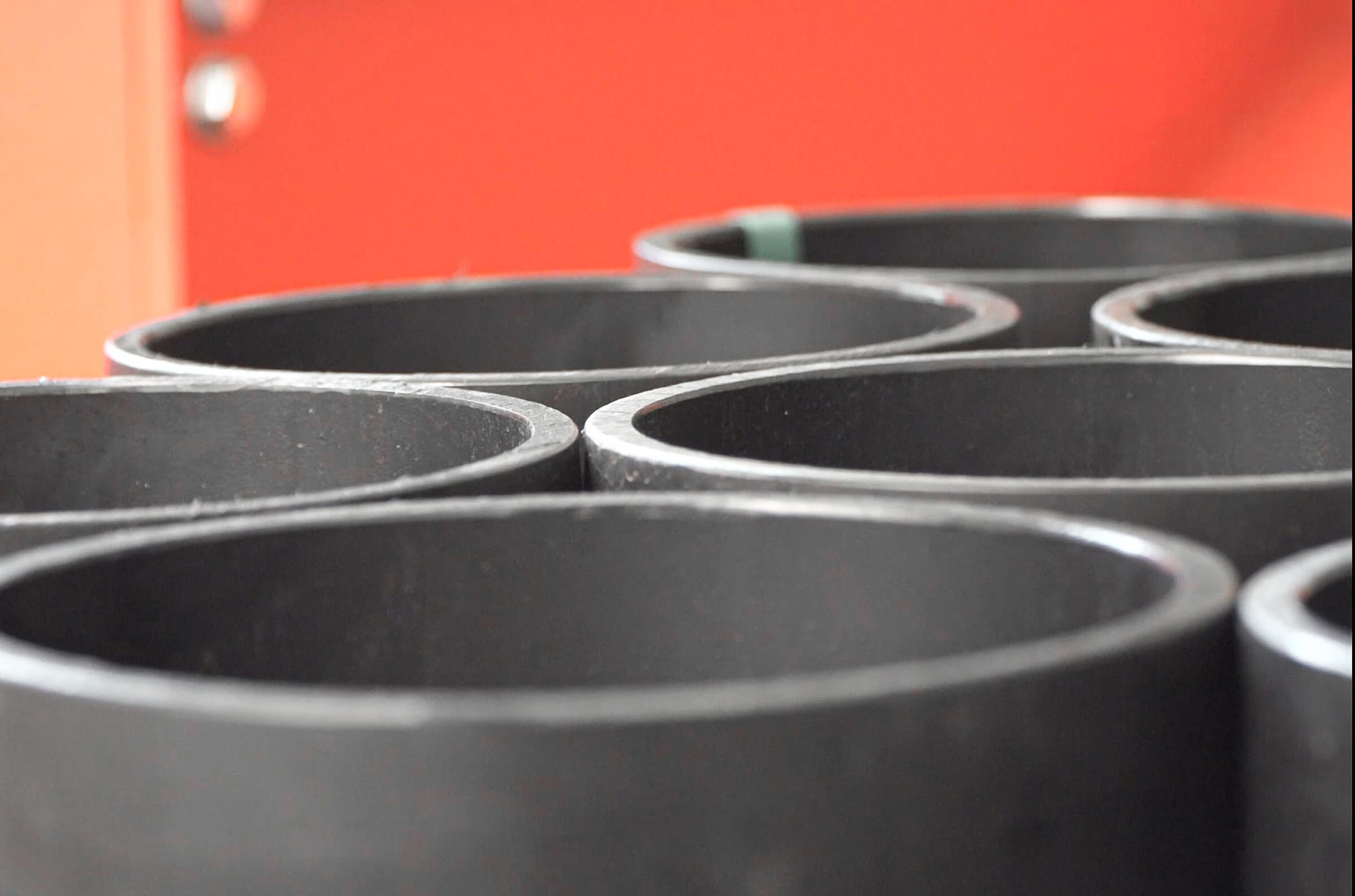

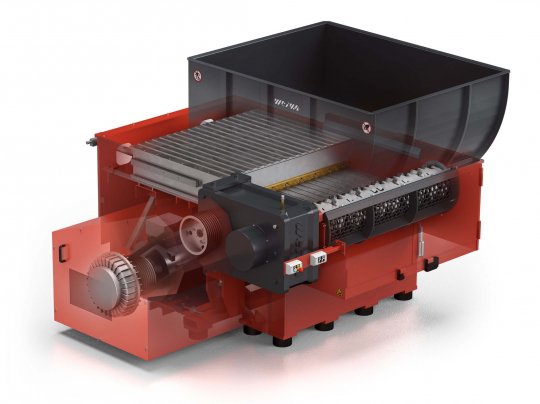

How does the shredding of plastic pipe waste work?

HDPE pipes are among the most difficult applications for shredding due to their dimensions, robustness and weight. Depending on the diameter, wall thickness and size, pipe scraps can usually be fed into the hopper of the WEIMA single-shaft shredder by conveyor belt, crane, wheel loader or forklift without manual preparation. The pipes are pressed against the rotating rotor by the hydraulic ram and uniformly shredded to a homogeneous material size. The screen size used below the rotor defines the particle size of the material. The material is usually transported by conveyor belt to the next step in the processing line.

Loading of WEIMA shredder with HDPE pipes

Inquire about an HDPE shredder today

Request a quote

Pipe recycling in the circular economy

Opportunities for recycling

Mechanical recycling

After pipes have been collected, sorted and washed, they are reduced to homogeneous regrind with the aid of shredders. From this, high-quality regranulate can be produced using extrusion equipment – the basis for the production of new plastic pipes as recyclate within the in-house recycling process.

Chemical recycling

In contrast to mechanical recycling, chemical reprocessing attempts to return products made from plastics to their chemical raw materials in order to produce new plastics. However, the separated fractions are not completely pure, which can lead to problems with precise formulations.

Did you know?

In 2017, nearly 800,000 tons of plastic pipe systems were produced in Germany.

Two-stage shredding with shredder and granulator

A WEIMA WLK 1000 single-shaft shredder for plastics and a WNZ 310/600 granulator shred voluminous PP-HD pipes (200mm diameter).

Example applications from industrial plastic pipe manufacturing

W5 series: Maintenance-friendly all-rounders with swing ram

With working widths of 1,400 mm, 1,800 mm or 2,200 mm, the W5 series takes on a wide variety of materials. The inspection flap and the lift-up screen basket make the single-shaft shredder particularly easy to maintain. Thanks to the wide conveyor belt cutout, large quantities of shredded material can be transported away quickly and cleanly.

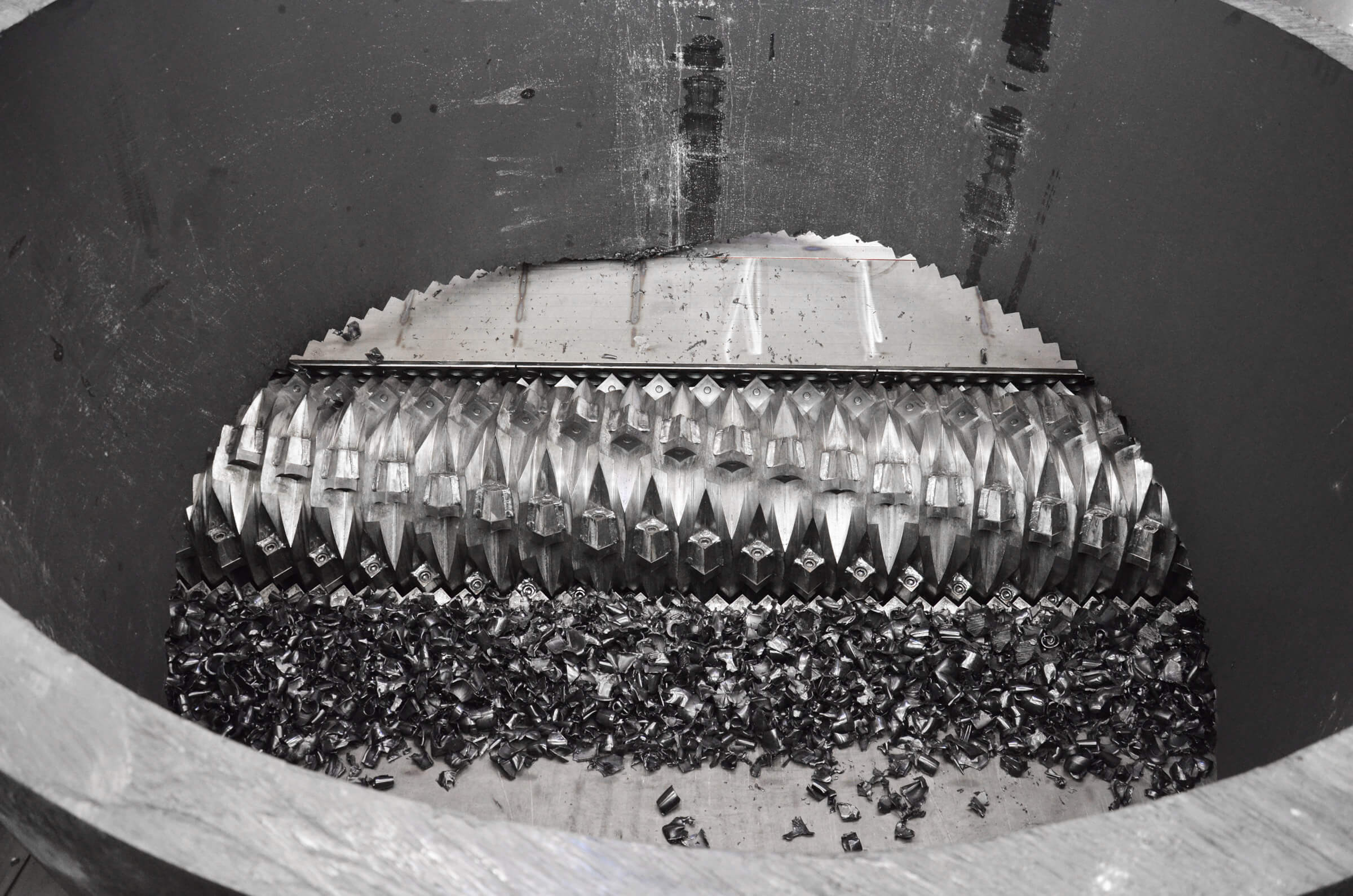

WEIMA W5 shredder interior view

Swing ram for particularly good material feed

The material feed using swing technology makes the shredder particularly compact, simplifies maintenance and allows more aggressive material feeding. Material already slides towards the rotor by gravity and is then pressed against it continuously or intermittently by the hydraulically movable swing ram. For even more aggressive feeding, the swing can optionally be equipped with a pusher.

Cilindro de trituração WKS

WLK series: High throughput plastic shredders

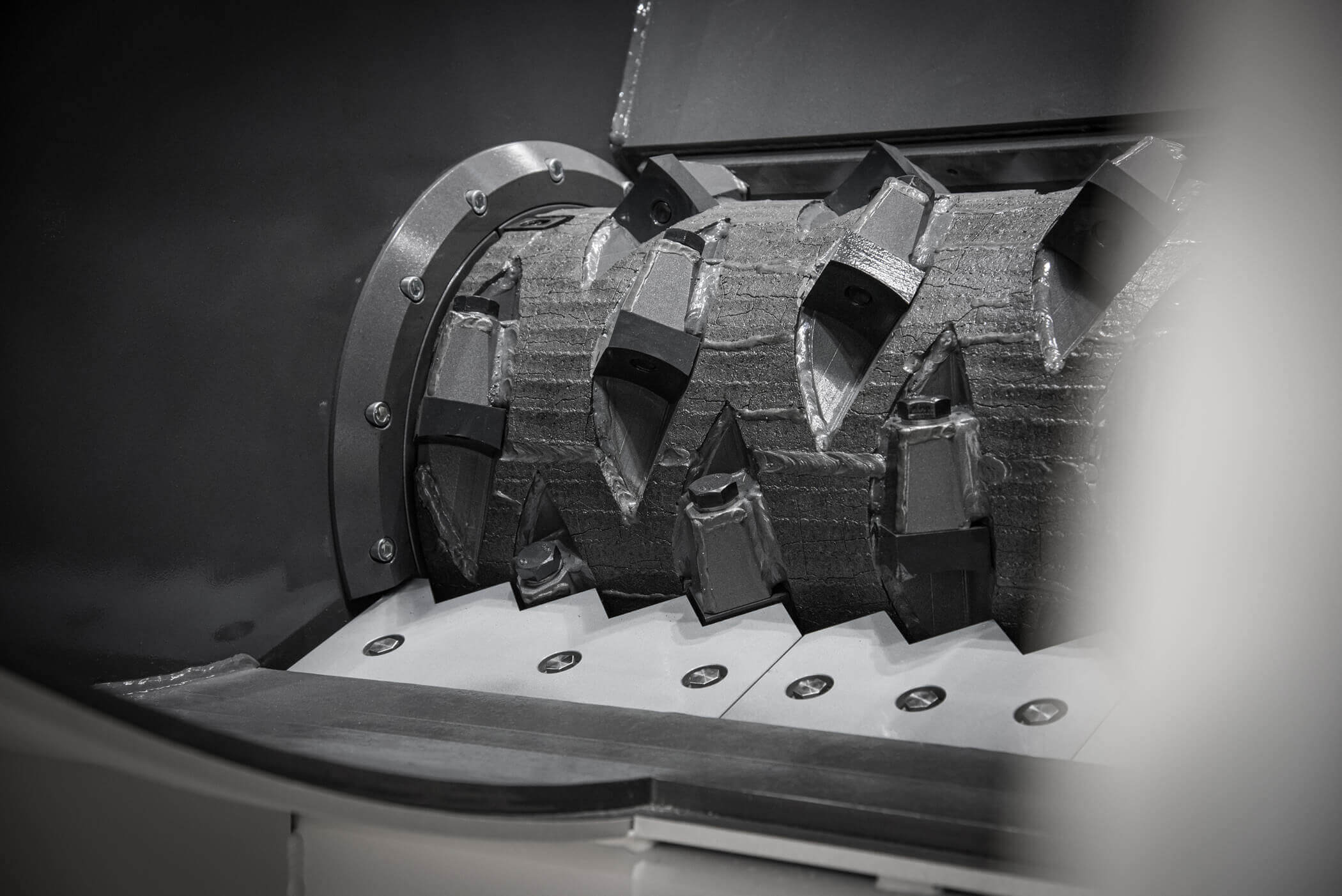

Machines of the WLK series are ideally equipped for a wide range of plastics tasks. The machine design is characterized in particular by durability and robustness. Thanks to the conveyor belt cut-out, all machines can be seamlessly integrated into any production line. They also offer numerous options in terms of drive and cutting geometry.

WEIMA WLK 1500 interior view

Heavy duty machine design

WEIMA shredders for processing highly abrasive materials can be protected with various options to reduce wear and thus downtime and maintenance costs. The heavy wall thickness of the machine frame makes WEIMA shredders particularly robust. The rotor can be reinforced with Vautid, the screen with Creusabro. To protect the cutting knives against the impact of foreign objects, large knives with edge lengths of up to 130 mm x 130 mm can be selected. If the number of knives is small. Vautid can also protect knife holders.

To avoid increased wear of the rotor face plates, we recommend the installation of replaceable Creusabro wear plates on both sides. The cutting chamber can also be reinforced and optionally lined with exchangeable Creusabro plates. Wear protection does not stop at the screen, which defines the material size. For particularly high wear, we offer a screen reinforced with Creusabro with a wall thickness of approx. 20 mm.

What is Creusabro?

Creusabro is a high performance wear resistant steel. Compared to low alloy wear resistant steels, Creusabro has a higher heat resistance. WEIMA uses Creusabro with a hardness of 58 HRC.

What is Vautid?

Vautid is a buildup welding material that can be applied to components as a welding alloy. In WEIMA shredders, Vautid with 62 HRC is applied.

What is Hardox?

Hardox it an abrasion resistant steel and is mainly used as wear plate with a hardness of up to 600 HBW. Depending on the requirements, different degrees of hardness can be applied.

Select your preferred drive:

Electromechanical drive

One of the most common drive options for single-shaft shredders is the electromechanical drive, which has proven itself thousands of times over. The power is transmitted by means of a standard motor, a specially developed WEIMA WAP gearbox and a V-belt. The speed can be flexibly adjusted.

High-Torque drive

The high-torque, multi-pole synchronous motor from Baumüller is produced in Germany and is characterized by its insensitivity to foreign bodies. Without gears, the drive resists shocks and vibrations and thus has a particularly long service life – even when shredding challenging material streams.

Acionamento de alto binário da Baumüller

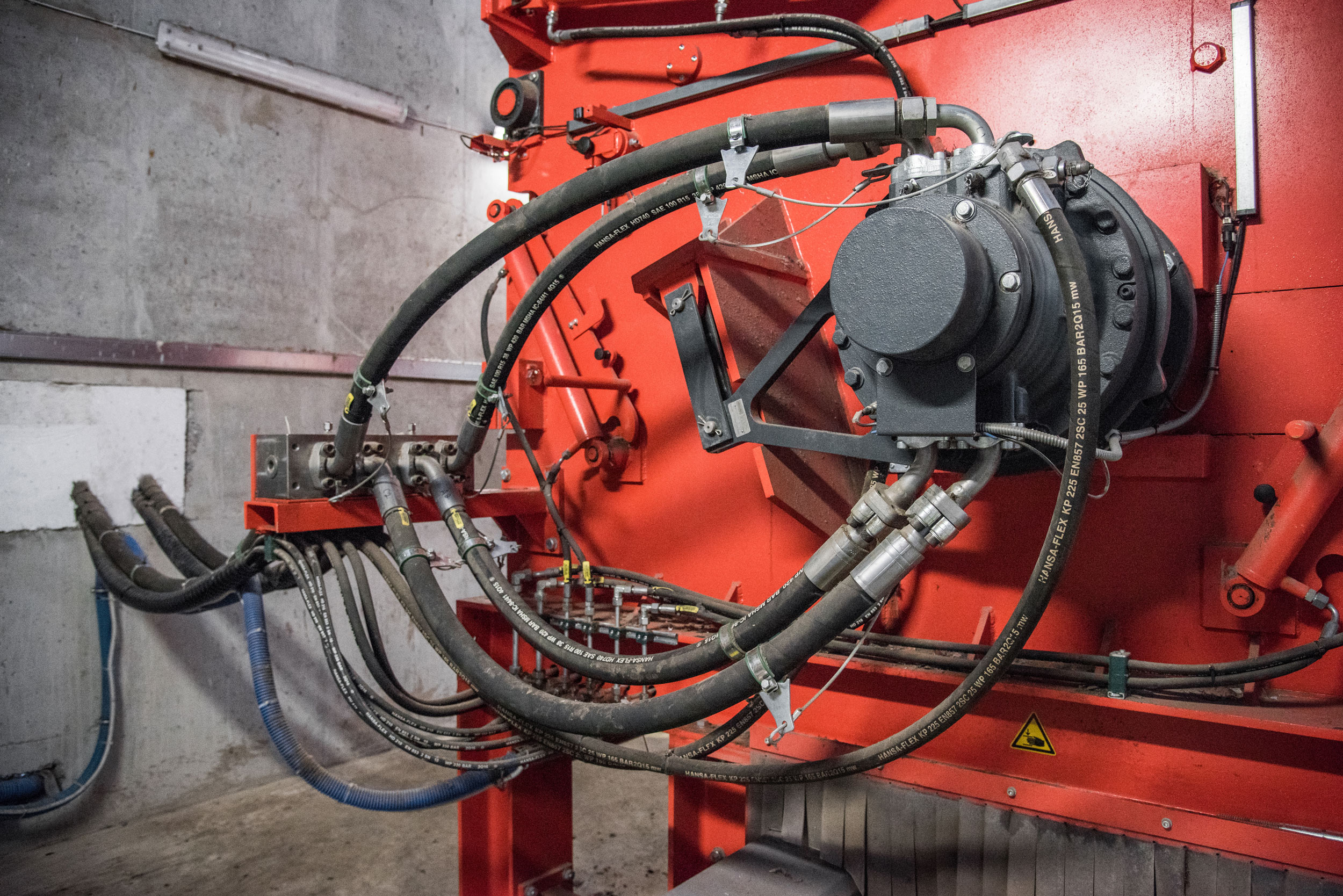

Hydraulic drive

Hydraulic drives from Hägglunds / Bosch Rexroth have no gearbox and are therefore particularly insensitive to many contaminants. Speed and torque can be adjusted without current peaks. The robust drive provides high torque at low kW power. The speed can be variably adjusted by means of a regulating pump.

Shredding of PE pipes

Only at WEIMA

Heavy-duty machine design

for long service life

Large feed hopper

for easy feeding of particularly big pipe cuttings

Easy maintenance

for minimized downtimes

Many drive options

for maximum throughput

Applied know-how

for minimized operating costs

Fast service

for highest customer satisfaction

All from one source:

Machines, conveyor technology, metal detection, support, spare and wear parts for customized solutions

HDPE plastic pipe shredding with a WEIMA S7.15 lift-up with 110 kW drive power

See for yourself

The WEIMA show room is equipped with shredding and briquetting machines of all sizes and technologies. This enables us to simulate your application as realistically as possible. You have the possibility to send us your material or visit us directly in Ilsfeld. From our gallery you have the best view directly into the cutting chamber. So you can observe the shredding process live.

Request an appointment now

Alternatively you can send us material for testing.

Click here for the form.