Tires and rubber shredding, disposal and recycling with WEIMA

Information about shredders for tire shredding and processing of used car tires

Did you know that more than one billion tires are disposed of worldwide every year? According to estimates, that adds up to more than 13 million tons of scrap tire waste. The need for suitable disposal solutions is correspondingly high. Tires are more than just round rubber bodies on our roads. They are made of a complex mixture of different materials such as rubber, steel and fibers. These components make them robust and durable, but are also responsible for their environmentally harmful nature if not disposed of properly. To avoid water, soil, and air pollution, appropriate technologies are required during processing. By efficiently shredding tires, valuable resources can be recovered - or they can be made usable for energy, for example for the production of cement. For this purpose, WEIMA offers various single-shaft shredders for shredding tires and rubber waste of all kinds.

Car scrap tire shredding in Korea

Secondary shredding of car tires with a hydraulically driven WEIMA PowerLine Shredder

Challenges in tire shredding

Shredding scrap tires is a technological challenge in many respects. In order to reliably shred the material combination of rubber, steel wire and tear-resistant fibers, a robust machine with a strong drive is required. Here WEIMA offers a suitable solution with the hydraulic drive. At the same time, user-friendly maintenance must be ensured, as tires usually cause high wear.

Shredded car tires on a conveyor belt

In the fast lane of scrap tire recycling with WEIMA

In the world of tire recycling, shredding is the key to effective disposal and recovery of valuable resources. WEIMA is proud to offer high quality shredders specifically designed for tire shredding.

Before | after: used tires

What materials are tires made of?

- Rubber: Tires are largely made of rubber, which consists of different types of rubber. Natural rubber and synthetic rubber are used to provide the required elasticity and durability of the tire.

- Steel: To improve the strength and structure of the tire, steel wires or steel belts are incorporated into the tires. These steel belts lead to increased stability and rigidity.

- Fibers: Tires can also contain textile layers, such as nylon or polyester fibers. These textiles give the tire additional strength and load-bearing capacity.

- Chemicals: A variety of chemical substances are used in the manufacture of tires, including vulcanizing agents, plasticizers, fillers, antioxidants and adhesion promoters. These chemical additives play an important role in improving tire performance and increasing durability.

The composition of a tire varies to a greater or lesser extent with the intended use. However, the basic structure is comparable in most cases, especially for classic passenger car tires.

Did you know?

Whereas in 1996 around 50% of used tires were still disposed of in landfills, today the figure is 4% in the EU. Globally, however, the statistics are less positive. Worldwide, the landfill rate is still a whopping 75%. We think this is more than capable of being improved!

What types of car tires are there?

There are a variety of tire types to meet a wide range of requirements and conditions. Summer tires are generally designed for warm temperatures and good performance on dry and wet roads, while winter tires are specifically designed for cold temperatures, snow and ice. All-season tires offer a combination of summer and winter tires and are a practical option for moderate weather conditions. All-terrain/off-road tires offer rugged construction and a rough tread for off-road use, while sport tires are designed for improved performance and grip on sporty vehicles. Truck/transport tires carry heavier loads and are designed for long-distance use, while racing tires are designed specifically for motorsports to provide maximum performance and grip on the track. For all listed types, WEIMA offers the appropriate shredders for shredding.

Used car tires before shredding

Request the right shredder for tires now

Request a quote

How to dispose of old tires?

The disposal of used tires varies from country to country. However, many countries have recognized that environmentally sound disposal brings many benefits and have issued appropriate regulations.

After the used tires are collected, shredding usually takes place in two stages. The pre-shredder first pre-cuts the tires to pallet-sized pieces. The secondary shredder then usually shreds the pre-shredded tires to a granule size of about 50 mm. This is ideal for further processing and for separating the different materials.

Shredded old car tires

Used tires are usually either recycled, reused, incinerated or landfilled. Recycling is an environmentally friendly method that involves shredding tires and separating the materials. Reuse is possible if the tires are still in good condition. Incineration can be used to generate energy, while landfilling should be avoided as it can have negative impacts.

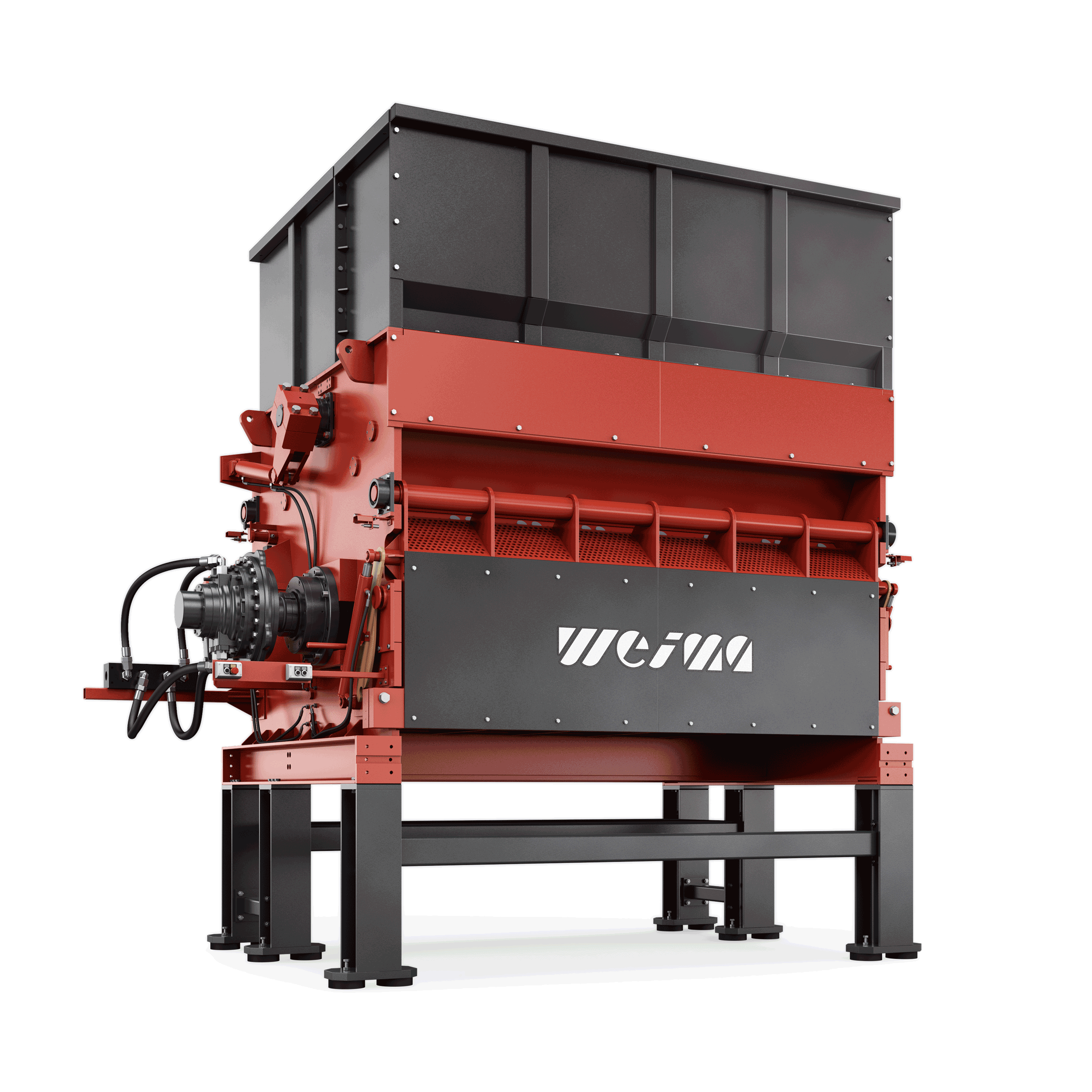

PowerLine: universal shredder with single-shaft technology for pre- or post-shredding

Performance that pays off. The PowerLine series takes on any form of waste, including scrap tires and rubber. Ideal as a shredder in multi-stage plants. Can be equipped with hydraulic drive, direct drive or power belt drive.

WEIMA PowerLine shredder

Good to know

In 2020, about 279 million tons of scrap tires were recycled in Korea.

Only at WEIMA.

Heavy duty machine designs

for long service life

Easy maintenance

for minimal down times

Various drive options

for maximum throughput

Fast service and support

for highest customer satisfaction

Everything from one source

machines, conveying technology, metal detection, support, spare and wear parts for customized solutions

WEIMA headquarters Ilsfeld (Germany)

Convince yourself.

The WEIMA showroom is equipped with shredding and compacting machines of all sizes and technologies. This allows us to simulate your application as realistically as possible. You are welcome to send us your material or to visit us directly in Ilsfeld. From our gallery you have the best view directly into the cutting room. This allows you to observe the shredding process live.

Request appointment now

Alternatively, you can send us material for testing. Click here for the form.

Car tyres before shredding