PowerLine 3000

Performance you can count on! The PowerLine takes on any form of waste, including dirty materials. It is ideal as a secondary shredder in multi-stage systems: after sorting the material out that is not ideal for the production of RDF, the valuable material remains and is ready for further size reduction. This machine comes equipped with a hydraulic drive, a direct drive, or a power belt drive.

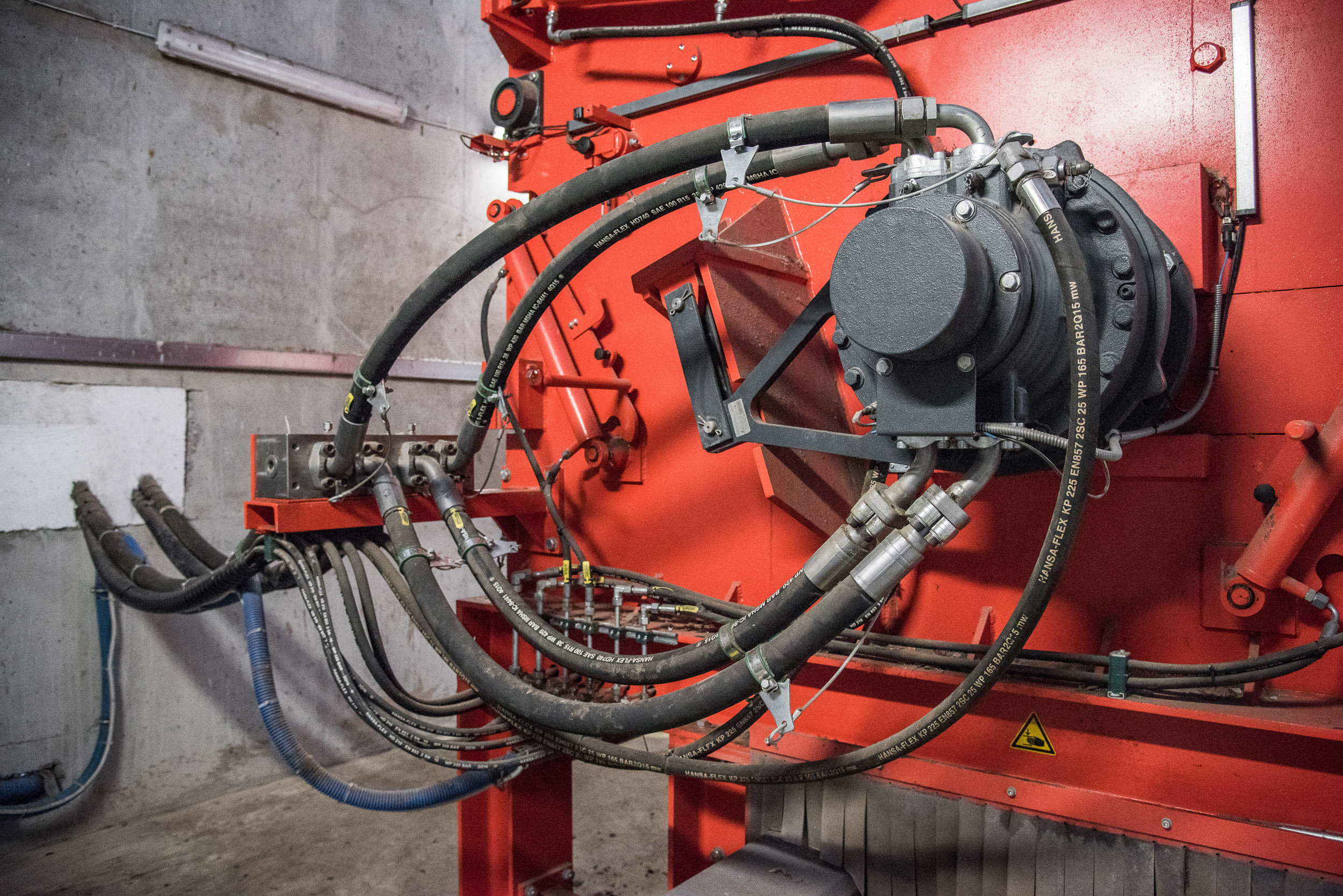

A WEIMA PreCut 2000 single-shaft shredder pre-shreds municipal solid waste for the production of refuse-derived fuels (RDF). Secondary shredding happens with a WEIMA PowerLine 2500 single-shaft shredder. Both shredders are equipped with a hydraulic drive by Hägglunds Bosch Rexroth.

We manufacture our control cabinets ourselves in our German factories, using only brand-name components. With the large touch display, you have all important data and settings at your fingertips. The flexible adjustment of parameters such as the rotor speed or the ram movement is thus easily possible. For challenging conditions, we recommend optional control cabinet cooling.

The shredders can be opened outward on both sides via a flap or door – at the front for work on the screen and at the rear for direct rotor access. This facilitates routine maintenance, such as knife rotation, or optimization of the cutting gap. Foreign materials can also be easily removed manually. Down times are reduced to a minimum.

The counter knives are user-friendly, adjustable from the outside via a screw system, and can be easily reversed when worn. In addition, they are protected by cover plates and positioned at an angle for an even more aggressive cut.

Material is fed to the rotor with a swing ram. The swing attachment, which is located on the outside of the pre-shredder, ensures maximum cutting chamber size. The swing ram can optionally be equipped with an additional pressing feature to hold the material more firmly against the rotor. In addition, turbo hydraulics are used for faster swing arm movements and result in higher throughputs.

Always lubricated bearings thanks to automatic central lubrication

The central lubrication system mounted on the side of the machine frame ensures that rotor bearings, swingarm bearings, screen bearings and inspection flap bearings are always optimally lubricated. This eliminates the need for manual lubrication by hand pump.

At the Swedish company Veolia Recycling Plastics Sweden AB, waste bins and other HDPE plastic waste from production are turned into new raw material with the help of a WEIMA PowerLine 2500 shredder and downstream wash line.

Due to its high solid dead weight, the PowerLine Rotor requires less torque for shredding. Vautid protection against increased wear is available as a full shell or in the form of welded seams. Side-mounted rotor face plates made of Creusabro® also protect against abrasive material flows. The shaft journals are bolted on both sides. Cutting blades in sizes 60, 80 and 100 mm can be flexibly selected.

Even if your production surfaces are not one hundred percent level: Thanks to our standard, adjustable heavy duty feet, the machine is guaranteed to have a firm hold.

You have the choice: our PowerLine shredders are available with a Hägglunds hydraulic drive, a high-torque drive by Baumüller or a conventional electromechanical drive. Your individual application always decides which one is the right one.

Hydraulic drive unit

In the eastern Polish town Chelm, the waste recycling company EkoPaliwa operates its new plant for the production of alternative fuels. At the center are two WEIMA PowerLine 3000 single-shaft shredders with powerful hydraulic drives, which are used as secondary shredders.

Easy integration into production lines or as a stand-alone solution

Optimally connected: WEIMA shredders have all common interfaces to ensure fast integration into existing production lines. Thousands of system solutions in cooperation with plant engineering partners worldwide speak for themselves. The elevated base frame offers plenty of space for all common conveyor belts – perfect for transporting shredded material away.

All FineCut shredders have a screen basket that can be swung upwards, on which the screen segments are screwed. They can be changed quickly and are protected against wear. With secondary shredders, a particle size of 30 - 150 mm can be achieved.

PowerLine Siebsegment

A WEIMA PowerLine 2500 single-shaft shredder shreds different types of HDPE pipes at a recycling plant of Remondis in Röstånga, Sweden.

There is always rush hour on the AmeyCespa plant site – every single day. The activity is mainly caused by…

Read more

LaFarge, worldwide-leading building materials producer with its head office in Paris has successfully installed…

Read more

Two WEIMA PowerLine 3000 single-shaft shredders with a powerful hydraulic drive used in secondary shredding absolutely take center stage here….

Read more

With the help of a flagship WEIMA PowerLine single-shaft shredder, Polymer Processors in Melbourne has successfully commissioned stage one of their plant upgrade. This adds thousands of tons of plastic recycling capacity to Australia.

Read more