In addition to the conventional electro-mechanical drive and the high-torque drive, the hydraulic drive is a powerful drive option for WEIMA shredders that has proven itself with customers around the world. The recycling specialist from Ilsfeld has been placing its trust in the cooperation with the hydraulics experts from Hägglunds / Bosch Rexroth for many years.

Every cycle has a beginning. And in recycling this is usually the shredding of waste and residual materials. Only then can further processing begin. In order to guarantee an optimum result with material flows of the most varied types, a tailor-made concept is required for the respective application. “Our customers expect machines they can operate around the clock“, explains managing director Andreas Mack, who has been with WEIMA since 2006. The machines and their components are exposed to extreme wear and tear. A robust design and high-quality components are the be-all and end-all of the shredding process. The drive train contributes significantly to the quality of the shredding result and must meet the high demands of the customers and the material. WEIMA trusts in Hägglunds / Bosch Rexroth for the hydraulic drive systems.

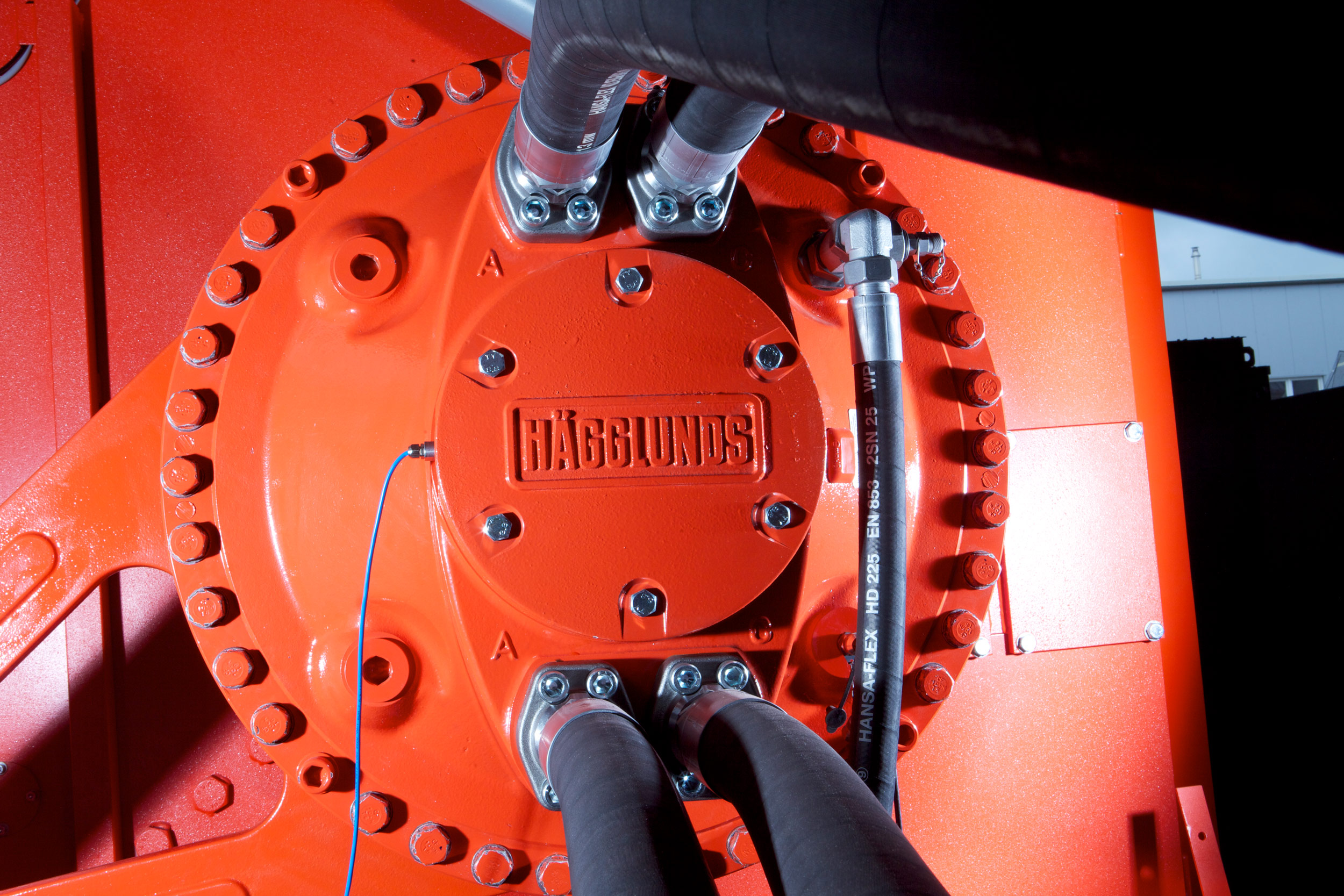

Hägglunds drive | Source: HansaFlex

Maximum performance in terms of torque and flexibility with hydraulic drives

The hydraulic drive has a decisive advantage, especially when heavily soiled material such as household or industrial waste, agricultural film or mixed waste is to be shredded: Since it does not have a classic gear unit that is subject to wear and tear from impacts, it is virtually insensitive to impurities. Damage to the machine and rotor can thus be significantly reduced. Even when used for shredding very flat materials such as filaments, big bags or PP, it enables an extremely high cutting force and a high torque and breakaway torque.

The Hägglunds drive also scores in terms of flexibility: “One of the biggest challenges for our customers is the changing input material, which can be small or large, light or heavy and possibly full of impurities,” reports Andreas Mack. “The ability to flexibly and continuously adjust the two factors speed and torque means safety and less risk for the customer“. In addition, a Hägglunds drive can switch between forward and reverse operation as often as necessary, even at full load. This is especially helpful when operators have to change the working direction several times to bring the material into the correct position.

Hägglunds hydraulic drive in action

Achieving great things together – The road to autonomous shredding

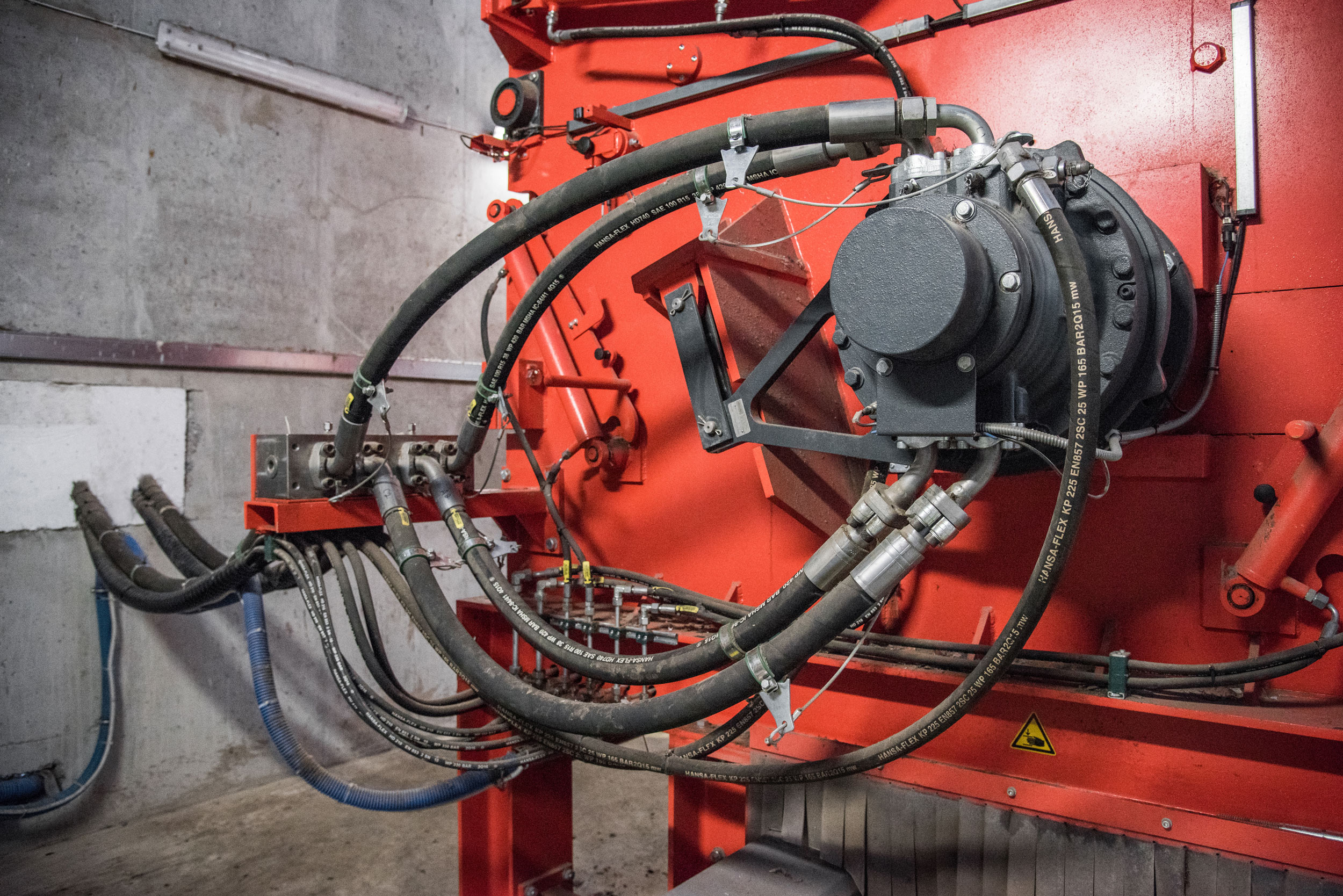

The cooperation between WEIMA and Hägglunds has existed for over a decade. Since 2008, the shredding specialist has been using drives from Hägglunds in many machines – from medium-sized machines of the WLK and WKS series to multi-stage shredding systems with WEIMA PowerLine and PreCut shredders. The joint development of digital solutions and the promotion of innovations in the recycling industry are also the focus of the cooperation – with forward-looking ideas. Andreas Mack mentions, for example, the vision of semi-autonomous shredders and regards the cooperation with Hägglunds as an essential building block for achieving this goal.

PowerLine 2500 single-shaft shredder with hydraulic drive

“In the future, I see fully automatic and self-regulating shredders that determine their operation based on sensors and data that the machines themselves evaluate,” enthuses Mack. This idea fits seamlessly with the condition monitoring and other connection options already used in Hägglunds drives.

„My vision for the coming years is an adaptive shredder that is able to decide what is best suited for a customer’s production”.

Andreas Mack

Managing Partner at WEIMA

WEIMA and Hägglunds are not only joining forces in development. The partners at Hägglunds also provide additional support in matters of customer service when it comes to special applications and are on site with WEIMA at customer operations. “We have a long-term and very good relationship with Bosch Rexroth and the Hägglunds team“, says Andreas Mack. “If we need a special solution that we cannot supply ourselves, we know from experience that we can always rely on Bosch Rexroth and Hägglunds.”

Servicing the hydraulic drive of a WEIMA shredder | Source: HansaFlex