BOPP film shredding and recycling

Information on professional recycling

Biaxially oriented polypropylene film (BOPP) is a stable film formed by stretching polypropylene film (PP) in both longitudinal and transverse directions. This thermoplastic is one of the most frequently used standard plastics in consumer products. It is particularly valued worldwide as a packaging material. BOPP films are characterized by their strength and transparency. WEIMA offers the right shredding solution for all types of BOPP film, be it classic transparent film or flower film, pearl white, metallised micro/macro-perforated film.

BOPP film shredding with WEIMA S5.20 lift-up | Hägglunds @boschrexrothglobal hydraulic drive | DIAXON

A WEIMA S5.20 lift-up single-shaft shredder, equipped with a powerful hydraulic drive by Hägglunds Bosch Rexroth, shreds BOPP film that is mostly used for packing – at DIAXON in Greece.

Typical BOPP waste types and forms

- Loose BOPP film and packaging film

- BOPP blankets casting film waste

- BOPP film rolls and film roll waste

- BOPP Lumps and start-up lumps

With WEIMA shredders you receive a turnkey solution for your offline BOPP production waste.

Waste forms at various points within the production line. For example, it can accumulate in the form of plastic lumps at the beginning and end of extrusion lines (ex. cast film extrusion). In addition, there are roll remnants that remain on the metal core. These are folded into so-called blankets and can also be processed using an in-house recycling line.

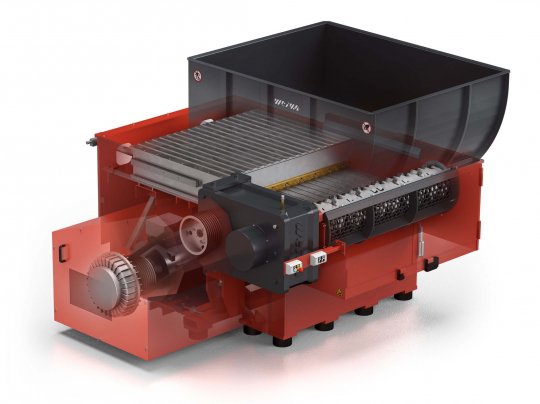

Proven shredders for BOPP film waste

WEIMA customer installations for BOPP applications can be found worldwide. Our references include well-known companies such as JINDAL Poly Films and Taghleef. They use WEIMA shredders for the recycling of so-called offline BOPP waste streams from their own production.

Economic and sustainable: BOPP recycling

Robust plastic shredders from WEIMA are versatile and flexible. Thanks to individual components that can be adapted to every application, such as the rotor, its cutting knives, the drive, the material feed as well as the material discharge, you always achieve the optimal shredding result.

BOPP waste can be fed directly in any form. Manual material preparation or pre-cutting is not necessary. The machine can be loaded by forklift, wheel loader, manually by hand or conveniently and automatically via a conveyor belt.

WEIMA S5 shredder with hydraulic drive shreds BOPP film waste and start-up lumps

Inquire about a BOPP shredder today

Request a quote

WLK Series: Highly productive plastic shredders

Machines of the WLK series are specially designed for plastics applications. With their extremely sturdy design and large rotor diameters, shredders of the S5 and S7 series offer almost unlimited possibilities for the shredding of plastic waste.

WEIMA WLK 1500 interior view

WEIMA W5 shredder interior view

W5 series: Maintenance-friendly all-rounders with swing ram

With the W5 series you can shred it all: from large-volume objects to tear-resistant fibers and films. With an innovative inspection flap for easy maintenance access and swing ram for optimized shredding.

Developed for flat materials such as films: The F-Rotor

The optimum coordination of rotor, knives and counter knives is crucial for the shredding result. The selection of the components suitable for the material requires a high degree of experience. The F-rotor, specially designed for films, is characterized by its controlled feeding behavior.

By the way: For particularly abrasive or dirty materials, we recommend wear protection made of Vautid.

WEIMA F-rotor

Perfectly integrated into your production line

In most cases BOPP materials are crushed to a particle size of approx. 30-80 mm. This is the ideal size for subsequent extrusion. In order to achieve the greatest economic benefit, the regrind produced is then reused in the production process of new film. This recycling of in-house production waste not only saves money and conserves resources. The reduction of voluminous, unwieldy residual materials also relieves and simplifies intralogistics. Employees can therefore devote themselves to higher-value tasks.

Loading by conveyor belt

BOPP film shredding with WEIMA S5.20 lift-up at Greek recycling company

Only at WEIMA

Extremely robust machine design

for the most difficult applications

Easy maintenance

for minimized downtimes

Many drive options

for maximum throughput

Fast service

for highest customer satisfaction

All from one source:

Machine, conveyor system, metal detection, support, spare and wear parts