Shredding and recycling big bags, bulk bags and fabric bags

Information on shredding and processing woven sacks, better known as FIBC or big bag (PP) transport bags

You’ll encounter it wherever heavy loads (particularly bulk goods) need to be transported quickly and safely: the popular and very rugged Big Bag. The English term caught on from the very beginning because it precisely describes what it is – a big bag. And it is extremely flexible to use. In addition to sea freight containers and europallets, big bags are standard equipment in any manufacturing industry that deals with logistics, transport and storage. But big bags are also made of fabric, which wears over time and with use. We will show you on this page how the subsequent proper disposal works in terms of the circular economy.

Shredded big bags briquetting with a WEIMA TH 1200

A WEIMA TH 1200 briquetting press compacts shredded big bags into solid briquettes.

What is a big bag?

Made from PP (polypropylene thermoplastic) plastic fibers, big bags are generally reusable bags that have a large opening along with loops and hold over 1,000 liters. Compared to wooden crates or metal containers, they are particularly light and flexible when unfilled. The product name Big Bag was originally the brand name of a German company. By definition, the fabric bags are called Flexible Intermediate Bulk Containers (FIBC for short). Outside of Germany, they are also known as bulk bags or jumbo bags.

Filled big bag with loops

Big bags on wooden pallets ready for loading

What are the types of big bags?

So-called U+2 Panel bags are among the most common big bag transport bags in the world. In addition, there are round big bags and so-called Q bags in a variety of sizes and dimensions. Filling is generally possible in three ways: via the classic open-top opening, a filling or closing skirt or a filling spout (channel). Emptying is also possible in three ways: turning the big bag over/upside down, via a spout at the bottom or a bottom that can be fully opened. There are four kinds of loops to choose from: classic loop straps, straight loops, tunnel loops and reversible loops.

How are big bags properly disposed of and recycled?

Shredding is usually the first step in waste processing or recycling, which is also the case with big bags. Bags that have been pressed into bales or are loose can be placed into the generous hopper of a shredder by forklift, conveyor belt or by hand. The interaction of the rotor, counter knives and ram means that the big bags are shredded to a uniform grain size of 60-80 mm. In doing so, it is important to reduce the fines content to a minimum.

Big bag recycling system with shredding and extrusion

Closing the loop: washing and extrusion

If the material is heavily contaminated, washing is necessary in the next step. As soon as the shredded big bags are clean, they end up in an extrusion plant where the material is melted and processed into re-granulate. The re-granulate can then be returned to the cycle and used as raw material for the production of new plastics.

Where are big bags typically used?

- Building materials (stone, rubble, sand, gravel)

- Production waste (plastic parts, rubber, carpet)

- Food (grain, nuts, beans, seeds, potatoes)

- Packaging waste (films, polystyrene, cardboard, containers)

- Wood (firewood, waste wood, wood chips)

- Recycling (granules, flakes, powder, wood chips)

The above list is a selection of applications for big bags and does not describe any recommendations. There are in addition many other industries where rugged woven big bags are used.

Shredding big bags with a WLK 1500 single-shaft shredder

Challenges when shredding big bags (FIBC)

To reduce the volume of rejected big bags, many users compress collected big bags into compact bales. This does not mean, however, that the bags are completely clean. In many cases, there are still residues, dust, dirt or foreign objects such as stones, sand or metal in the used bags. These objects should be sorted out as much as possible before shredding in order to avoid increased wear. However, if the big bags are mostly clean, there is no reason why they cannot be used directly.

Another special feature of big bags is their typical tear resistance due to the PP fiber fabric. For this reason, it is important to select the right cutting geometry and to adjust the shredder to the input material. With over 40,000 machines delivered, WEIMA is your experienced partner.

Did you know?

The Swedish company Boxon produces big bags in Indonesia that consist of up to 96% recycled PET bottles. The equivalent of 50 bottles are required for a 2 kg big bag.

Nature as an example: using WEIMA to shred raffia strings, yarn and bast

Raffia is the natural counterpart to big bag plastic fibers made of polypropylene (PP). The main cultivation areas are Madagascar, South, West and East Africa. Raphia belongs to the palm family and is derived from its very long leaf fibers. Due to its tear resistance, raffia is ideal for the production of coarse yarn, knitting, mats, baskets, hats or other garments. Raffia is also used as a tying or braiding material for the cultivation of fruit and vegetables. WEIMA also offers the right shredding solution for shredding this natural product.

WEIMA W5.18 single-shaft shredder shreds big bags for subsequent recycling

Request your big bag shredder now

Request a quote

Heavy duty machine design protects against increased wear

WEIMA shredders for processing highly abrasive materials can be protected with various options to reduce wear and thus downtime and maintenance costs. The heavy wall thickness of the machine frame makes WEIMA shredders particularly rugged. The rotor can be reinforced with Vautid and the screen with Creusabro. Large knives with an edge length of up to 130 mm x 130 mm can be selected to protect the cutting knives against the impact of foreign bodies. In addition Vautid can protect knife holders.

In order to avoid increased abrasion of the rotor face plates, we recommend installing replaceable Creusabro wear plates on both sides. The cutting chamber can also be reinforced and optionally lined with replaceable Creusabro plates. The wear protection is not confined to the screen that defines the material size. In the event of particularly high wear, we offer a screen reinforced with Creusabro with approx. 20 mm wall thickness.

Revestimento de rotor Vautid

Shredding big bag bales (FIBC) with a WEIMA WLK 1000 single-shaft shredder

With discharge conveyor

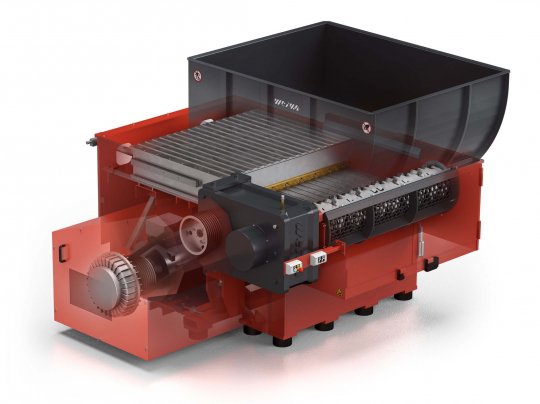

WLK and S5 | S7 series: highly productive plastic shredders

Machines from the WLK series are specially designed for plastic applications. With their extremely rugged design and large rotor diameters, shredders from the S5 and S7 series offer almost unlimited application possibilities for shredding plastic waste.

Big bag recycling with a WEIMA WLK 800 shredder

W5 series: Maintenance-friendly all-rounder with swinging arm ram

With working widths of 1,400 mm, 1,800 mm or 2,200 mm, the W5 series accepts a wide range of materials. The inspection flap and the upward-swinging screen basket make the single-shaft shredder particularly maintenance-friendly. Thanks to the wide conveyor belt cutout, large quantities of shredded material can be transported away quickly and cleanly.

WEIMA W5 shredder interior view

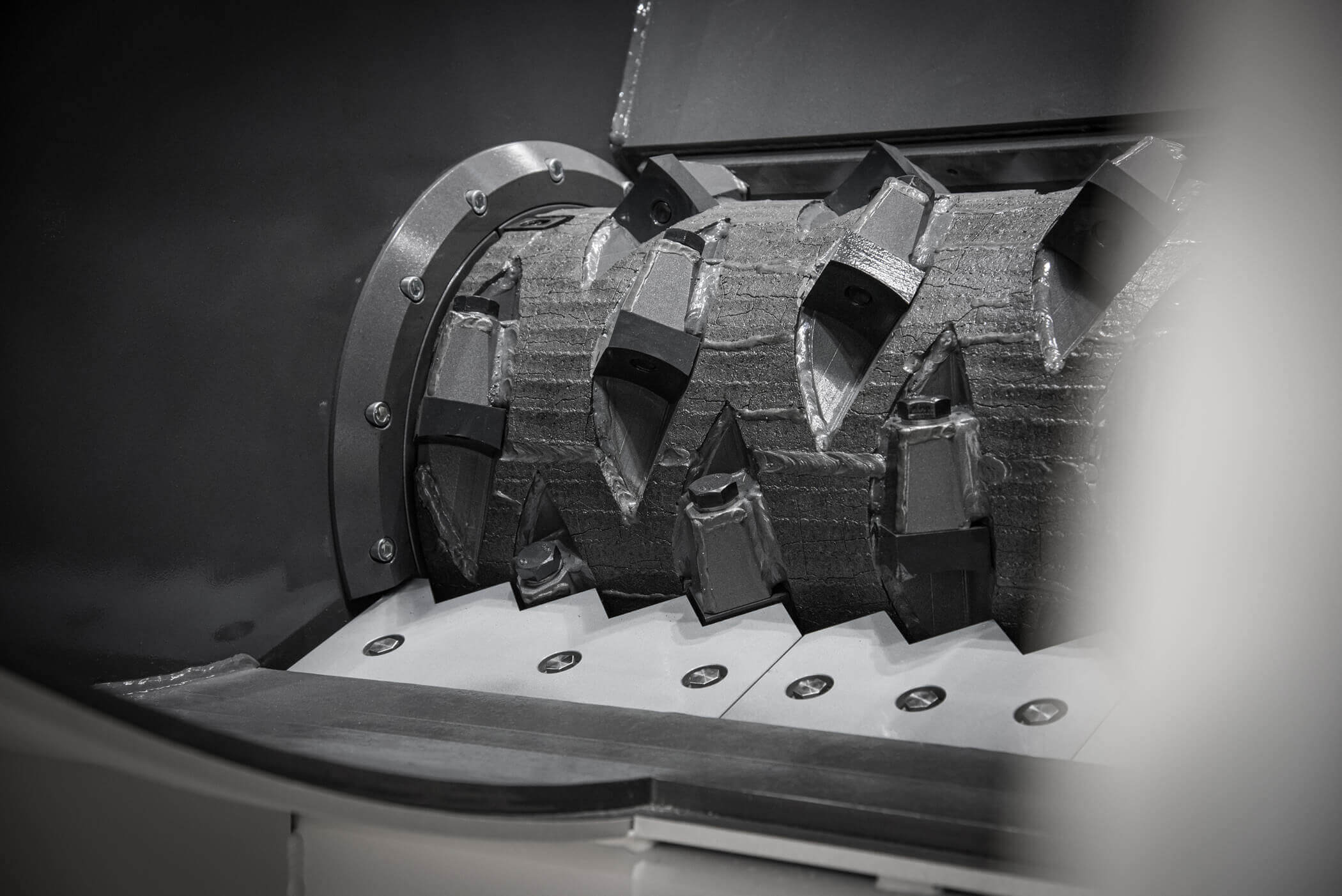

Ideal for flexible materials – the F rotor

WEIMA is known for its precise cutting geometries. The F rotor is a prime example of this. Its cutting geometry and special knife arrangement are ideal for shredding flexible materials such as fibers and films. For extreme applications and contaminated material streams, we recommend additional wear protection made of Vautid, which protects the rotor.

WEIMA F rotor for flexible material

Choose your preferred drive type:

High-torque drive

The high-torque, multipole synchronous motor from Baumüller is also made in Germany and features low sensitivity to foreign objects. The fact that there is no gearbox means that the drive withstands impacts and vibrations and gives it a longer life cycle even when shredding challenging material flows.

Acionamento de alto binário da Baumüller

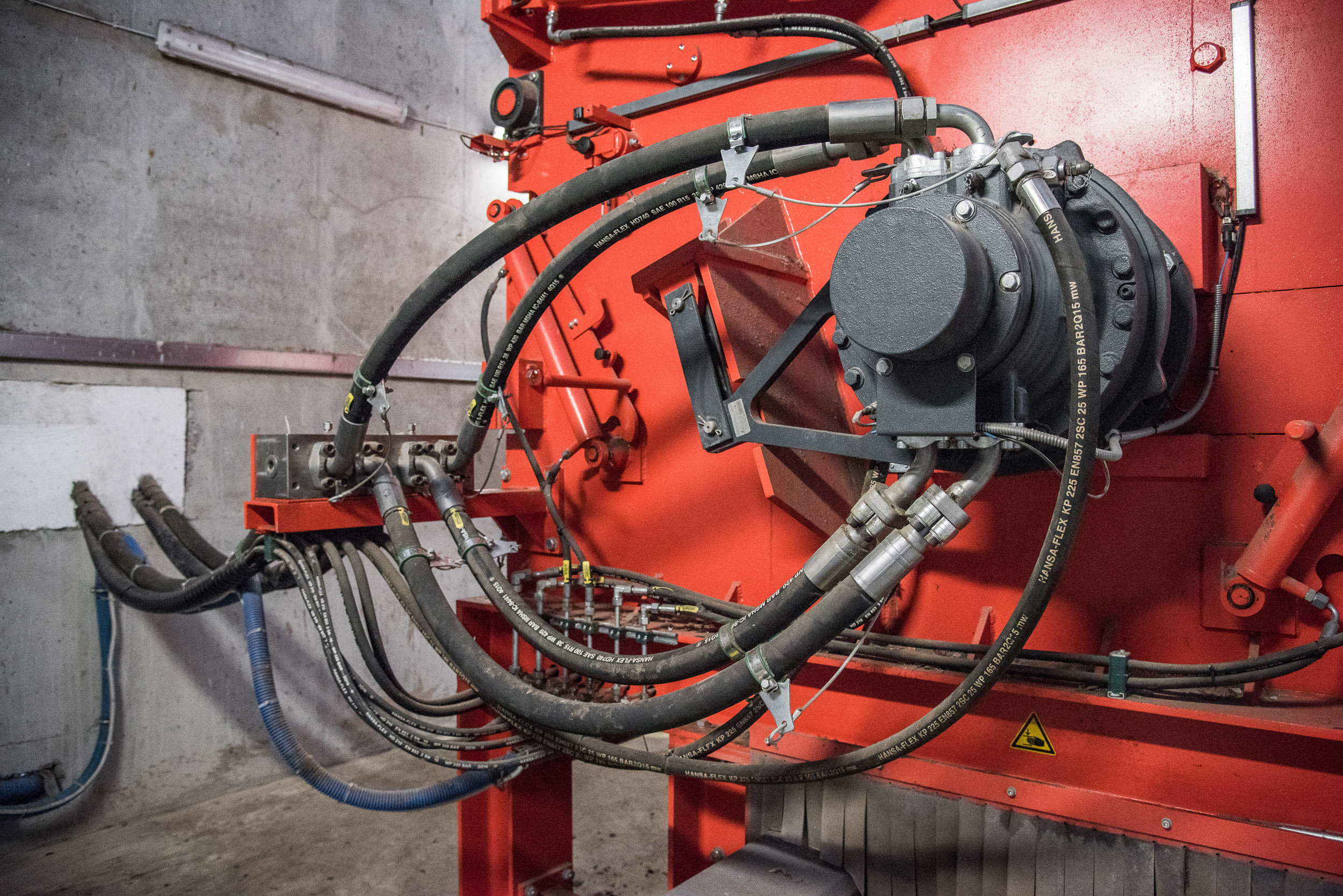

Hydraulic drive unit

Hydraulic drive

Hydraulic drives from Hägglunds / Bosch Rexroth do not have a gearbox and are therefore particularly resistant to a number of extraneous materials. Rotational speed and torque can be adjusted without creating power peaks. The rugged drive ensures high torques at low kW power. The rotational speed can be variably adjusted using the control pump.

Available only at WEIMA

Heavy-duty machine designs

for long service life

Easy maintenance

for minimum downtimes

Many drive options

for maximum throughput

Fast service

for highest customer satisfaction

Everything from a single source:

Machines, material handling technology, metal detection, support, spare and wear parts for tailor-made solutions

WEIMA headquarters Ilsfeld (Germany)

See for yourself

The WEIMA showroom is equipped with shredding and compressing machines of all sizes and technologies. This allows us to simulate your application as realistically as possible. You can send us your material or visit us personally in Ilsfeld. From our gallery, you will have the best view directly into the cutting chamber. This will allow you to observe the shredding process live.

Alternatively you can send us material for testing:

Click here for the form

Baled big bags for recycling