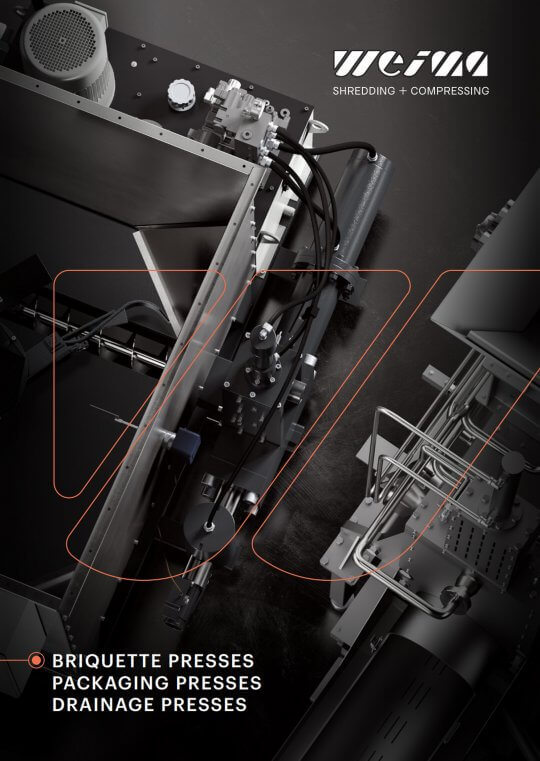

TH 1200

The modular design of the TH 1200 allows exact adaptation to suit your existing premises or production conditions. Briquettes can be made from materials such as wood, polystyrene, foam, light alloy, paper or biomass – with throughput rates and briquette quality to meet high industrial demands (precondition: material residual moisture <= 18%). Nearly every individual solution can be achieved, e.g.: Duo, trio or quattro designs to increase throughput rates and availability of the machine.

A WEIMA TH 1200 briquetting press compacts shredded big bags into solid briquettes.

The galvanized hopper, into which the material to be briquetted is fed either manually via a conveyor belt or a screw conveyor, is equipped with a rotating agitator and a discharge screw at the bottom. It is available in dimensions of 1,400 x 1,400 mm or 2,000 x 2,000 mm, depending on the required buffer volume. The machine can be used in automatic mode by means of fill level monitoring.

WEIMA WLK 1000 single-shaft shredder shreds packaging foam, which is then pressed into solid briquettes by a TH 1200 briquetting press.

We manufacture all briquetting press control cabinets ourselves in our German plants in Ilsfeld, Abstatt and Annaburg. For this purpose, we use only brand-name components – and this also applies to our machine control system. The high-quality Siemens PLC control system with touch display optimally coordinates the components with each other, which makes it possible to achieve a consistently high briquette quality.

A WEIMA TH 1200 briquetting press compacts wood shavings into solid briquettes.

Longer briquetting, more pressing cycles with large hydraulic oil tank and large pressing mechanism

The larger the hydraulic tank, the longer it takes for all of the oil to heat up. This has a positive effect on the working time of the briquette press. The hydraulic unit is also temperature controlled. All in all, this results in significantly increased throughput due to fast pressing cycles and a more robust overall machine.

Dust-reduced compression for more safety and cleanliness

Briquetting is carried out without the addition of adhesives or binders, which makes subsequent use for energy purposes harmless. Thanks to a closed pressing system, the continuous escape of dust is also effectively prevented. This protects your employees and keeps your production halls clean.

If required, individual components, such as the tank, the press unit or the oil tank, can be flexibly positioned. We call this option "Vario”. The machine adapts to your individual production requirements – not vice versa. Integration into existing production lines is extremely convenient. This means that all avenues are open to you, even for future optimization.

The TH 1200 is the only machine with clamping technology that produces rectangular briquettes measuring 150 x 60 mm with variable lengths. These can be ideally stacked, packaged and then sold at a profit. The voluminous hydraulic unit allows multi-shift operation with high throughput rates. Highly compressed briquettes are produced with the aid of a generously dimensioned clamp cylinder.