M8.28

The WEIMA M8.28 shredder with twin-shaft technology is ideal for use as a pre-shredder. It is characterized by high throughput rates and shreds a wide variety of material streams for further processing, for example sorting or separation.

With the large touch display, you have all important data and settings in front of you at a glance. This makes it easy to flexibly adjust parameters such as the cutting shaft speed. With the Siemens PLC control system, not only the shredder but also the peripherals including conveyor belts, separation technology and secondary shredders can be controlled centrally via PROFINET and PROFIBUS systems. Material flows can thus be processed in an energy-efficient manner and maintenance can be optimized.

M8.28 touch display

Constantly lubricated bearings

thanks to automatic central lubrication

The central lubrication system ensures that moving machine parts such as the cutting shaft bearings are always optimally lubricated at all times. This eliminates the need for manual lubrication.

The lateral inspection flap can be opened hydraulically. This facilitates access to the cutting table including cutting shafts for routine maintenance. Foreign matter can also be easily removed manually in this way.

Lateral inspection flap

Flexible adjustments of the cutting table due to Easy Exchange System

The cutting table is easy to change thanks to the EES (Easy Exchange System). It can be lifted out of the machine frame together with the cutting shafts and easily replaced. Even with changing material flows, the shredder can thus be optimally adapted to customer requirements.

Flexible machine setup thanks to separate PowerPack

The 280 kW PowerPack can be set up flexibly: directly next to the machine, a few meters away or even in a separate room. An enclosure protects the motors from corrosion, moisture and dirt. If required, soundproof panels can be selected for the enclosure to minimize noise generation.

The cutting shafts can be configured with eight to twelve cutting disks, depending on the required throughput and particle size. The size of the shredded material depends on the number and width of the cutting knives.

M8.28 cutting table

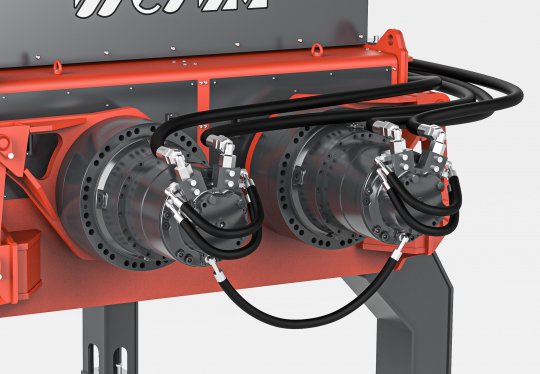

For the twin-shaft shredders of the M series, WEIMA relies on powerful hydraulics from high quality manufacturers. The hydraulic drive is very responsive – and this at a low connected load.Stopping, starting and reversing is possible even under full load. The speed (15-40 rpm) and torque are infinitely variable without a frequency converter.

M8.28 with hydraulic drive

Use in multi-shift operation thanks to hydraulic oil cooling

To compensate for temperature differences in the hydraulic oil, shredders of the M series have an oil cooling system with air cooling. This ensures long operating times without downtime. The voluminous oil tank is equipped with a micro-filter system and thus guarantees the purity of the oil for a particularly long service life.

The cutting shafts are designed to be particularly resistant to abrasive materials and foreign substances such as sand, metals or other contaminants. The cutting knives are made of extremely abrasion-resistant Hardox® 500 steel to protect them against wear and abrasion.

Shredding abrasive materials

The M series can not only be operated via the touch display, but can also be controlled via remote control. Functions such as starting and stopping the shredder, opening and closing the maintenance flap, reversing the cutting shafts and emergency stop can be conveniently monitored. Optionally, the shredder can be controlled via a smartphone app. Function parameters such as throughput, operating hours, maintenance intervals and fill levels can also be accessed there.

Operation via remote control

Shredding particularly large items thanks to large hopper volume

The standard version of the hopper has a capacity of five cubic meters. For feeding particularly voluminous parts or large quantities of material, this can be expanded to eight cubic meters. Filling by gripper is thus conveniently possible.

Optimally linked: WEIMA shredders have all common interfaces (PROFINET, PROFIBUS) to ensure fast integration into planned or already existing production lines. Thanks to the low loading edge, the shredder is ideally suited for direct filling via gripper, forklift or wheel loader, but also for conveyor belts. The elevated base frame offers plenty of space for all common conveyor belts. This means that large quantities of shredded material can be transported quickly and cleanly.

Looking for a suitable secondary shredder?