G.200

With the WEIMA G.200 you receive a modern high-performance press for the draining and subsequent compressing of food, beverage and detergent packaging and containers. The drainage unit presses up to 4.2 m³ of material per hour with a degree of pressing of up to 99% into handy 200 mm diameter pellets. These then only have a residual moisture of 3 - 30%. This is ideal for further processing in downstream recycling processes.

The length of the discharge pipe can be extended individually up to five meters. In contrast to a screw press, no conveyor belt is necessary for the discharge into a container or a tipping trough due to the increased discharge of the WEIMA presses. Thus, the press can be optimally placed according to your spatial requirements.

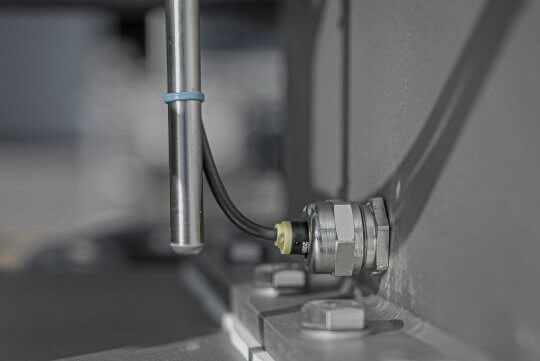

In order to be able to use the press in fully automated operation, the feed hopper can be equipped with a filling level sensor. With its help, upstream systems (conveyor belt) can be stopped/started automatically as soon as the maximum filling quantity of the hopper is reached. A continuous material flow prevents overfilling of the hopper.

You have the choice between different hopper volumes: 220 l, 600 l, 800 l, 1,200 l or 2,000 l. In addition, a manual or automatic hopper lid can be fitted as a safety and hygiene protection.

Hygienically flawless thanks to optional hygienic design

Safe and clean. Thanks to the cleanable design, WEIMA drainage presses maintain food safety, meet hygiene standards, and simplify cleaning procedures. This means that down time can be minimized.

The use in automated multi-shift operation is possible without any problems. Thanks to oil cooling using the heat exchanger method, the hydraulic oil can be kept at a constant operating temperature without overheating.

The Siemens control system with touch display allows intuitive setting of parameters such as the press force and time or the repress function. Precise diagnostic messages ensure minimal downtime. In addition, complete networking in the PROFINET system is possible. In this way, upstream and downstream systems such as conveyor belts or a lifting and tilting station can be controlled in a user-friendly manner.

DID YOU KNOW?

To ensure the long-term use of the G series, we use high-quality stainless steel. This protects the machine body and the control cabinet from wear and corrosion while simultaneously remaining low-maintenance and hygienic.

If required, the machines of the G series can be equipped with a pre-cleaning system. A multitude of nozzles mounted inside the press pre-clean the press and loosen coarse material residues. This simplifies subsequent manual cleaning. Five maintenance hatches facilitate access to the machine for cleaning as well as any maintenance work.

Optionally, the use of a fully automatic cleaning system is possible. This integrated cleaning system cleans the drainage press automatically. Nozzles inside the machine clean the press at a rate of up to 20,000 l/h. The integrated software controls the process.

If required, liquid discharge can be automated with the aid of level sensors in the product drain pan. The level sensors control the pumping out of the pressed material and automatically switch off the recycling press when downstream processes come to a standstill. We use screw pumps to discharge pasty liquids and radial pumps for liquid materials.

In order to rinse off any remaining product buildup (e.g. yogurt residues) from the discs, a post-cleaning unit in the form of spray nozzles can be fitted to the discharge tube. The cooling water from the oil cooling system can be used for this purpose.

A horizontal agitator in the feed hopper can be selected as an option. Continuous material circulation prevents bridging in the hopper and thus ensures constant material feed.

The wall of the pressing chamber is perforated to allow the emptied liquid to drain off. The sieve size can be individually adapted to your material properties. For pasty materials such as yogurt or sour cream, round holes up to twelve mm in diameter are usually selected. For liquids, on the other hand, sieve holes as small as 4 mm are possible. In any case, it is important that fine particles from the packaging do not get into the drain pan together with the liquid.