Electronic waste | e-waste (WEEE) shredders

Information about shredders for the recycling and disposal of electronic products (WEEE)

Electronic waste is a rapidly growing problem worldwide, with an estimated 53.6 million metric tons generated globally in 2019, according to the Global E-Waste Monitor 2020. This staggering amount of waste is expected to reach 74.7 million metric tons by 2030, posing significant environmental and health risks. However, only 17.4% of this e-waste was collected and recycled in 2019. As the demand for electronic devices continues to rise, it is essential that we adopt efficient and sustainable solutions to manage the e-waste crisis. That's where shredding comes in.

Shredding electronic waste is an essential step in the recycling process, as it enables the recovery of valuable resources while reducing the volume of hazardous waste. Electronic devices often contain valuable metals like gold, silver, and copper, which can be extracted through shredding and other separation technologies. In addition, shredding helps reduce the volume of electronic waste, making it easier and more cost-effective to transport and process.

Wow!

A single smartphone contains about 40 different elements.

What is electronic waste (WEEE)?

Electronic waste, or WEEE (Waste electrical and electronic equipment), is a term used to describe discarded electrical or electronic devices. It encompasses a wide range of products – from old computers, smartphones, and televisions to large appliances like refrigerators and washing machines. With rapid technological advancements and the constant demand for newer, better products, the volume of e-waste is increasing at an alarming rate, posing significant environmental and health risks.

Collection and sorting of electronic waste (e-waste)

Classifications of WEEE

- Large Household Appliances: Refrigerators, washing machines, air conditioners, etc.

- Small Household Appliances: Vacuum cleaners, irons, toasters, etc.

- IT and Telecommunications Equipment: Computers, printers, telephones, mobile phones, etc.

- Consumer Electronics: Televisions, radios, cameras, etc.

- Lighting Equipment: Fluorescent lamps, LED lamps, etc.

- Electrical and Electronic Tools: Drills, saws, sewing machines, etc.

WEEE can be broadly classified into six main categories according to the European Commission.

Origins of e-scrap

Electronic waste, also known as e-waste, has its origins in the rapid development of the electronics industry and the widespread use of electronic devices. The first electronic devices, such as radios and televisions, were built in the early 20th century, and the electronics industry expanded rapidly after World War II. The development of personal computers in the 1970s and the widespread adoption of mobile phones in the 1990s further accelerated the growth of the electronics industry and led to a surge in e-waste.

The short lifespan of electronic devices, coupled with the rapid pace of technological change and consumer demand for new products, has contributed to the proliferation of e-waste. As a result, e-waste has become the fastest-growing waste stream in the world. The improper disposal and management of e-waste can have serious environmental and health consequences, highlighting the importance of proper e-waste recycling and disposal.

E-scrap / waste piling up

The electronic waste | e-scrap | WEEE recycling process – step-by-step:

Collection: E-waste is collected from households, businesses, and other sources and transported to a recycling facility.

Sorting: The e-waste is sorted into different categories based on the type of device and the materials it contains.

Shredding: Electronic devices are shredded into smaller pieces using specialized shredders to facilitate the separation of materials.

Separation: The shredded e-waste is then subjected to various separation techniques to isolate different materials, including metals, plastics, and glass. These materials are then sent for further processing or sold to manufacturers as raw materials.

Refining: Valuable metals like gold, silver, and copper are further refined to increase their purity and recover more of the metal.

Disposal: Any hazardous materials that cannot be recycled or recovered are disposed of safely and responsibly.

It's important to note that the specific recycling process can vary depending on the type of electronic device and the recycling facility. Additionally, some recycling facilities may have additional steps in the process, such as testing and refurbishing devices that can be reused.

Shredder vs. Notebook

Challenges of e-waste recycling

Recycling e-waste is a complex and demanding process due to the diverse composition of electronic devices. They often contain hazardous materials, such as lead, mercury, and cadmium, which require careful handling and disposal. Additionally, extracting valuable metals like gold, silver, and copper from e-waste can be labor-intensive and expensive. The United Nations Environment Programme provides more information on the challenges of e-waste management.

Used computers e-scrap

WEIMA shredders can handle your electronic scrap.

As electronic waste continues to be a pressing environmental concern, the importance of efficient and safe shredding of e-waste is increasingly apparent. When it comes to shredding e-waste, there are several factors to consider, including size reduction, durability, safety, energy efficiency, versatility, material recovery, eco-friendliness, and ease of maintenance. The shredders manufactured by WEIMA are designed to meet all these requirements, making them some of the best shredders for e-waste. Let's take a closer look at the various features of WEIMA shredders that make them ideal for shredding electronic waste.

Shredding of a desktop computer

Good to know.

Recycling one million laptops saves the energy equivalent of electricity used by 3,500 homes in a year

Shredding of used copper cables e-waste for recycling

E-waste recycling has several benefits, including:

Environmental protection:

E-waste often contains hazardous materials like lead, mercury, and cadmium, which can contaminate the environment if not disposed of properly. Recycling e-waste helps prevent these hazardous materials from polluting the air, water, and soil.

Resource conservation:

Electronic devices often contain valuable resources like metals and plastics that can be recovered through recycling. Recycling e-waste helps conserve these non-renewable resources and reduces the need for new resource extraction.

Energy conservation:

Recycling e-waste requires less energy than mining and refining new resources. Recycling one million laptops saves the energy equivalent of electricity used by 3,500 homes in a year, according to the EPA.

Economic benefits:

Recycling e-waste can generate revenue through the recovery of valuable resources. It also reduces the costs of waste disposal and helps companies comply with regulatory requirements.

Hard drives and floppy discs shredding

Sad but true.

E-waste is the fastest-growing waste stream in the world.

The Urgent Need for Electronic Waste Recycling: Shred, Recover, and Save.

E-scrap recycling is crucial for our environment as it helps to conserve resources, reduce waste, lower carbon emissions, and prevent hazardous materials from contaminating the environment. Without proper recycling, e-waste can cause serious health risks to humans and wildlife. Therefore, e-scrap recycling is a crucial step towards achieving sustainability and ensuring a better future for generations to come.

Shredded consumer electronics (e-scrap)

Why WEIMA shredders for e-waste recycling?

Size Reduction Efficiency:

WEIMA shredders are engineered to effectively reduce the size of electronic devices, promoting efficient separation of materials.

Durability and Robustness:

Built to handle tough materials like metal and plastic, WEIMA shredders boast superior durability and reliability.

Advanced Safety Features:

Equipped with advanced safety features such as interlocks and emergency stop buttons, WEIMA shredders prioritize worker safety.

Energy Efficiency:

Designed for high efficiency and low energy consumption, WEIMA shredders deliver cost-effective operation.

Versatility and Flexibility:

Capable of handling a wide range of electronic devices, from small gadgets to large appliances, WEIMA shredders are incredibly versatile.

Valuable Material Recovery:

WEIMA shredders are engineered to maximize the value of recycled materials, enabling the recovery of valuable resources like metals and plastics.

Eco-Friendliness:

WEIMA shredders minimize environmental impact, with features like low-noise operation (e.g. two-shaft and four-shaft shredders) and reduced emissions.

Easy Maintenance:

Designed for easy maintenance, WEIMA shredders have accessible parts and clear instructions for repairs, minimizing downtime and maximizing productivity.

How does the WEEE Directive regulate electronic scrap recycling?

The WEEE Directive was established by the European Union in 2003 to regulate the disposal and recycling of electronic waste. Producers of electronic devices are responsible for financing the collection, treatment, and recycling of their products, with a target of 65% of all electronic waste being collected and recycled. The directive also regulates the disposal of hazardous materials in electronic devices and requires the establishment of collection systems and certified recycling facilities. The WEEE Directive promotes sustainable waste management practices and reduces the environmental impact of electronic waste in Europe.

E-waste

Request the right shredder for your e-waste (WEEE)

Request quote

WLK series: highly productive plastic shredders

Machines of the WLK series are specially designed for plastic applications of all kinds. They are highly robust and durable. S5 and S7 shredders are equipped with an extra-large rotor, making the shredders very flexible to be used for heavy-duty jobs.

Did you know?

The value of raw materials in e-waste was estimated to be worth $57 billion in 2019.

Shredding of refridgerators for recycling

W5 series: Maintenance-friendly all-rounders with swing ram

With working widths of 1,400 mm, 1,800 mm or 2,200 mm, the W5 series takes on a wide variety of materials. The inspection flap and the lift-up screen basket make the single-shaft shredder particularly easy to maintain. Thanks to the wide conveyor belt cutout, large quantities of shredded material can be transported away quickly and cleanly.

WEIMA W5 shredder interior view

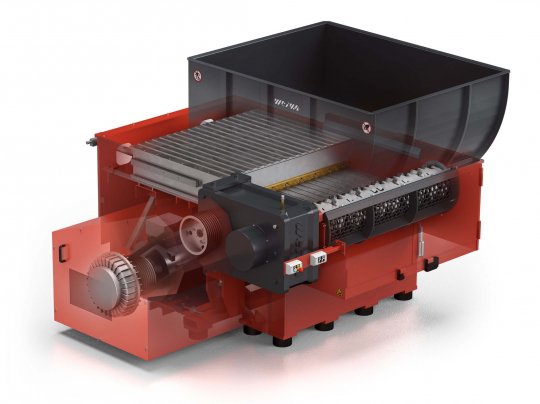

ZM four-shaft shredder: For clean production waste

ZM series machines are ideal for shredding long, bulky and voluminous materials. Their large feed hopper offers sufficient space and can be conveniently filled by hand, conveyor belt or forklift. ZM shredders have a cutting unit with two clearing shafts as well as two cutting shafts, which are characterized by their aggressive material intake. Compared to single-shaft shredders, four-shaft shredders cut at a slower speed and do not have a material pusher. The noise level is correspondingly lower, and the throughput is consistently high. A screen that can be mounted below the cutting unit defines the desired particle size of the output material.

WEIMA ZM four-shaft shredder

Only at WEIMA.

Heavy duty machine designs

for long service life

Easy maintenance

for minimal down times

Various drive options

for maximum throughput

Fast service and support

for highest customer satisfaction

Everything from one source

machines, conveying technology, metal detection, support, spare and wear parts for customized solutions

WEIMA headquarters Ilsfeld (Germany)

Convince yourself.

The WEIMA showroom is equipped with shredding and compacting machines of all sizes and technologies. This allows us to simulate your application as realistically as possible. You have the possibility to send us your material or to visit us directly in Ilsfeld. From our gallery you have the best view directly into the cutting room. This allows you to observe the shredding process live.

Request appointment now

Alternatively, you can send us material for testing. Click here for the form.

Shredded copper cables