Waste wood | scrap wood shredders, grinders and chippers

Information about grinders | chippers for shredding and disposing of waste wood, residual wood, demolition wood, bulky waste and packaging wood

Every year, around 10 million tons of waste wood are generated in Germany that need to be disposed of or recycled. This includes first and foremost waste from the construction and demolition industries, followed by industrial waste wood, so-called used wood from bulky waste and municipal waste – and, of course, packaging residues such as pallets or crates. After collection and sorting, there are two options: Recycle scrap wood and use it as a basis for the production of particleboard. Or use it thermally to generate energy | heat.

In both cases, WEIMA's single- or multi-stage shredding technology is used to either coarsely crush the waste wood first or to reduce it to a homogeneous chip size. If required, we can also supply the appropriate conveying technology, including metal separation via magnet, or an entire heating system, or we will be happy to advise you.

Chop saw wood cuttings shredding with a WEIMA WLK 1500 shredder @Kloboucká lesní, Czech Republic

Watch as the powerful WEIMA WLK 1500 single-shaft-shredder takes on diverse wood cuttings at Kloboucká lesní in the Czech Republic. This top-performing industrial-grade shredder is designed to process tough materials, shredding large volumes of wood waste quickly and efficiently.

What is waste wood? Origin and characteristics

According to the German Waste Wood Ordinance (AltholzV), used products and articles made of wood as well as wood composites and materials are referred to as waste wood. This includes packaging, furniture and primarily construction timber and demolition wood. They differ from uncontaminated industrial residual wood by-products (such as sawdust from a sawmill) or also residual wood from forestry operations (forest residual wood or weak wood), which by definition does not count as waste wood. However, there are also special features such as firewood or wood from hydraulic engineering.

The AltholzV also regulates the removal, recovery as well as disposal of waste wood and divides waste wood into four categories (based on the pollutant load): Waste wood category A I to IV. In addition, there is PCB waste wood, which contains polychlorinated biphenyls. In general, material utilization (for example, the use of wood chips as a base material for the production of chipboard) is classified as being of higher value than energy utilization (incineration).

WEIMA offers a suitable shredding solution for all waste wood classes, from A1 to A4.

Wood waste shredding at Appalachian Lumber with a WEIMA WLK 10 wood grinder

Appalachian Lumber is a family-owned business that was founded in 1982, and is located in the rolling foothills of the Blue Ridge Mountains in Wilkesboro, North Carolina (about 90 miles northwest of Charlotte). The office and plant facilities include more that 64,000 square feet of total space.

Attention! Contaminants!

Waste wood is an important part of the circular economy and represents a valuable resource. However, it is often also contaminated with pollutants or interfering substances. These include coatings, binders and hardeners, paint or wood preservatives of various groups (e.g. inorganic, organic, coal-tar containing), which makes material recycling more difficult. How deeply wood preservatives have penetrated usually depends on the product. Railroad sleepers or electricity pylons have usually been completely saturated in order to be as weather-resistant as possible. For traditional home use, solvent-based wood preservatives are simply applied by roller, brush or spray. Nevertheless, many varnishes and paints contain color pigments containing heavy metals, such as lead carbonate, or are contaminated by plasticizers.Not all waste wood contains pollutants. Often, they simply have interfering substances such as metal staples, fittings, concrete, plaster or parts made of plastic adhering to them. Separation is usually achieved by shredding and subsequent metal separation or material separation.

Energy recovery from waste wood

Impressive figures: 80 waste wood power plants in Germany produce around 800 megawatts of energy annually with the help of approx. 7.7 million tons of waste wood – with a calorific value of 11,000 - 15,000 kJ/kg. The use of waste wood for the production of electricity is regulated by the Federal Immission Control Act (BImSchG). Waste wood of categories A I and A II may be burned in small combustion plants with a nominal heat output of up to 30 kilowatts without immission control approval. Plants for the combustion of waste wood with wood preservatives must meet special requirements.

Although the energetic use of waste wood is more environmentally friendly compared to primary energy generation, material use should always be the first goal – in line with cascade utilization.

Source: Abfallratgeber Bayern

Source: LUBW

Source: BMUV

Source: Umweltbundesamt

Material recycling of waste wood | Used wood becomes a new product

Regardless of whether it is used for energy or material recycling – in both cases, the waste wood must first be pre- and post-shredded to a consistent chip size using a shredder. In the production of wood-based materials such as particleboard, this is particularly important to ensure high quality. It has been calculated that, on average, just under one third of a particleboard produced in Germany consists of waste wood of categories A I and A 2. Corresponding pollutant limits must be complied with in accordance with the Waste Wood Ordinance. In Italy, the proportion is up to 90 percent, as there are no legal requirements. In Denmark, up to 61 percent. The use of waste wood for the production of OSB boards or MDF boards is still the exception.

Chipboard made of wood waste

Practical examples and references: Waste wood recycling with WEIMA

WEIMA delivers over 1,000 machines per year. Many of them are used for the processing of all types of waste wood. You can find an excerpt of current reference projects here.

Request your wood waste shredder now.

Request a quote

Stage construction scrap wood | waste wood for sustainable entertainment

When you think of reclaimed wood, the first things that come to mind are bulky waste and pallets. This WEIMA customer in England shows that parts of the well-known X-Factor and The Voice television show stages still offer entertainment value even after they have been used. In the middle of the action: a large WEIMA Holz | Altholz single-shaft shredder. It will definitely make it through to the next round...

Didi you know?

Statistically, this results in an annual quantity of 113 kilograms of waste wood per inhabitant in Germany.

Large primary crusher for waste wood such as pallets: The WEIMA Woodwolf

The Woodwolf crusher series machines belong to the classic coarse pre-shredders. Unlike single-shaft shredders, they do not have a rotor and a counter-knife. Material is therefore not cut, but crushed. For this purpose, a 1,000 mm diameter screw, which lies horizontally in the machine body, is used. It crushes and tears pallets, boxes or furniture to approx. DIN-A4 sized pieces. These can then be transported further to the secondary shredder via a conveyor belt.

WEIMA Woodwolf

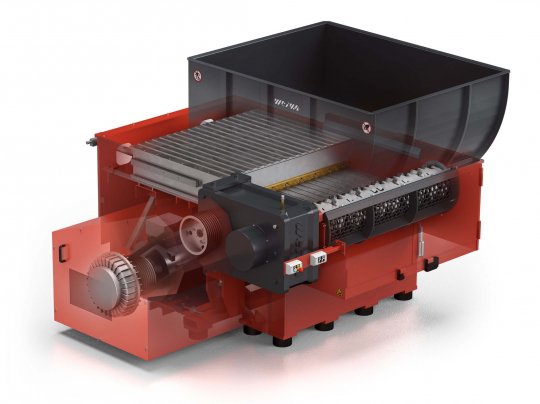

WLK 1500 single-shaft shredder

The WLK 1500 shredder with single-shaft technology is designed for high throughput rates and is particularly suitable for processing waste wood, softwood, hardwood and more. Different equipment options ensure optimum adaptation to every application. The shredder can also be ideally integrated into a two-stage solution.

WEIMA WLK 1500 interior view

Wood pallets shredding with WEIMA

Learn more about shredding pallets with WEIMA shredders here:

W5 series: Powerful all-rounder with practical inspection flap

The ideal shredders for high-volume residual wood. With the W5.14-22 series, you can shred everything from large-volume objects to tear-resistant fibers. With generous inspection flap for easy maintenance access and compact swing-arm pusher for an optimized shredding process.

WEIMA W5 shredder interior view

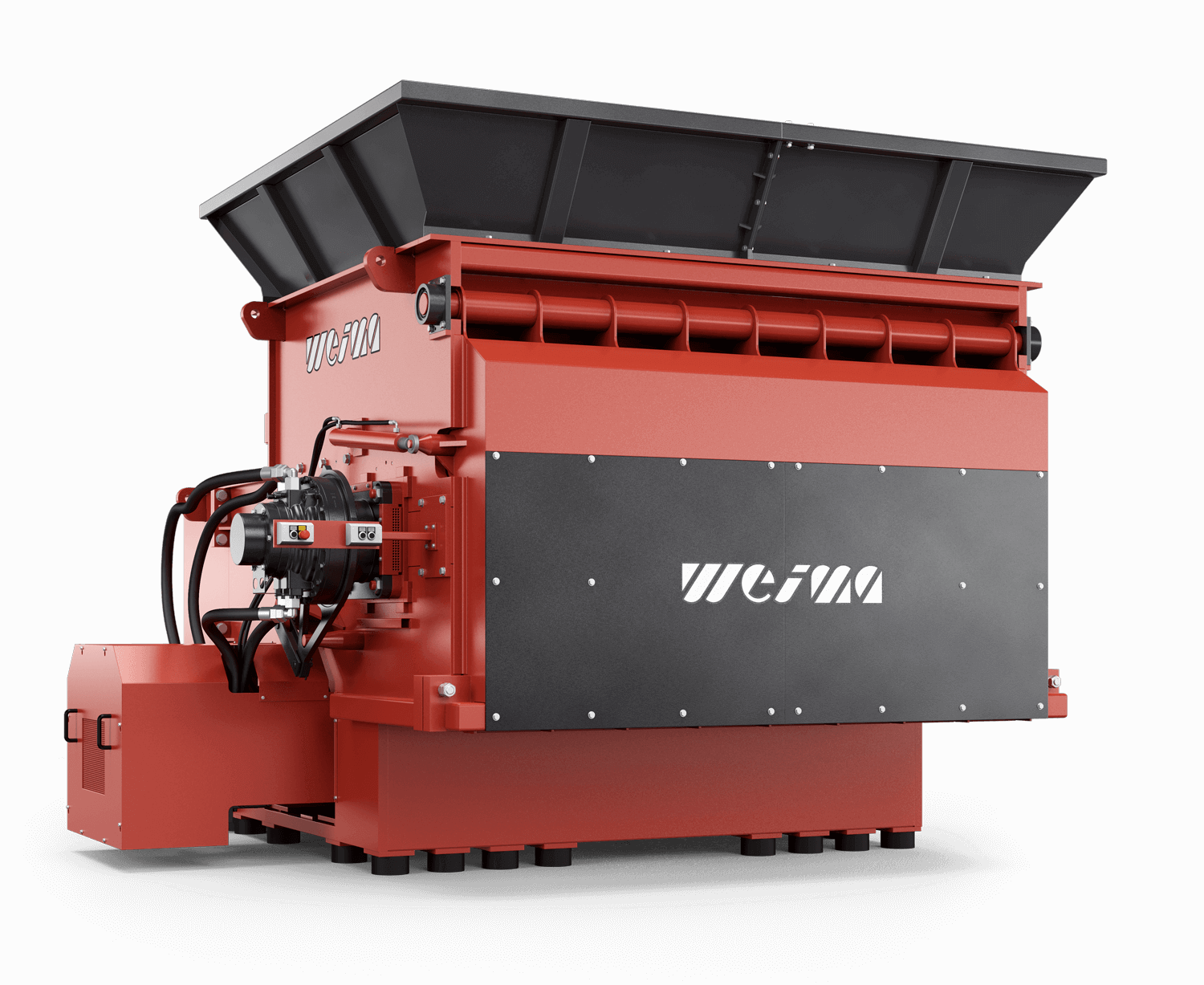

S5 and S7 series: Robust endurance runners for extreme throughputs

The shredders of the S5 and S7 series are designed for extreme tasks. Here, the machines have been setting standards for years in terms of stability, functionality, throughput and availability. A variety of different sizes and options guarantee customer-oriented solutions for almost all applications. Due to the extremely stable design, the series offers almost unlimited application possibilities for the shredding of recyclable materials. More than 80 different equipment details are available for customized individual solutions and applications.

WEIMA S7.25 single-shaft shredder

This combo is only available at WEIMA

Heavy duty machine designs

for long service life

Easy maintenance

for minimal down times

Various drive options

for maximum throughput

Fast service and support

for highest customer satisfaction

Everything from one source

machines, conveying technology, metal detection, support, spare and wear parts for customized solutions

WEIMA headquarters Ilsfeld (Germany)

Try before you buy.

The WEIMA showroom is equipped with shredding and compacting machines of all sizes and technologies. This allows us to simulate your application as realistically as possible. You have the possibility to send us your material or to visit us directly in Ilsfeld. From our gallery you have the best view directly into the cutting room. This allows you to observe the shredding process live.

Request appointment now

Alternatively, you can send us material for testing. Click here for the form.

Nails and screws on waste wood are not a problem for WEIMA