Pallets, also called transport pallets, are used globally for the safe transport and storage of stackable goods. There are different materials from which pallets are made: for example wood, plastic, corrugated cardboard and sheet metal. The most common are pallets made of wood. Disposable pallets are usually made of cheap softwoods – the boards and squared timber are simply nailed or screwed together. One of the best known is the euro-pallet with standardized dimensions and materials. WEIMA offers suitable shredding machines for all types of pallets.

Shredding and recycling pallets

Information on proper disposal

Pallets and waste wood shredding with a WEIMA WLK 1500 @ Bropack, Germany

A WEIMA WLK 1500 single-shaft shredder shreds pallets and waste wood from the production at Bropack in Dornham, Germany.

Why shred pallets?

Pallets can be both a blessing and a curse. Pallets are the ideal helper for logistics tasks. However, wooden pallets in particular take up valuable storage space when they are no longer used. The result: endless, meter-high mountains of discarded transport pallets. This can be remedied by waste management companies that collect the pallets. However, this is expensive and only partially economical. The more efficient solution is to use shredders specially designed for pallet processing. They shred pallets into wood chips, which can then be used as an energy source for your own heating system or sold for profit.

Pallet types

- Pallet made of solid wood, e.g. one-way pallet, euro-pallet

sustainable, very resilient, easy to repair - Pallet made of pressed wood, e.g. INKA or chipboard pallet

environmentally friendly, light, nestable/stackablebr - Pallet made of plastic, e.g. hygienic pallet, clean room pallet

low weight, durable, hygienically advantageous - Pallet made of corrugated cardboard, e.g. light pallet

recyclable, low weight, environmentally friendly

Pallets are available in different materials and in various shapes/sizes. Each of them has its own right to exist and has specific advantages and disadvantages, depending on the application.

All pallets have one thing in common:

WEIMA shredders shred them.

Heating with pallet waste

In Frankenthal, Kartoffel Kuhn shreds used wooden pallets into chips with a WL 15 single-shaft shredder. These are then used to heat the buildings.

EPAL euro-pallets – the famous exchangeable pallet

With eleven boards, nine wooden blocks and 78 nails, the europool pallet has taken the hearts of logistics companies by storm. The reusable pallet is manufactured according to DIN EN 13698 and is used in particular in the transport industry. The so-called EPAL1 pallet has a length of 800 mm, a width of 1,200 mm and a height of 144 mm. It weighs approx. 25 kg with a load capacity of approx. 1,500 kg. If the base is flat and solid, the maximum load on stacking is 4,000 kg. The original pallets have the typical EPAL branding and various country codes, registration numbers and license numbers. It is estimated that about 500 million EPAL1 pallets are currently in circulation worldwide. (Source: EPAL)

EPAL euro-pallets

Reasons for non-exchangeable EPAL pallets

- Broken boards

- Splintered top or bottom boards

- Missing boards

- Split or missing blocks

- Protruding blocks

EPAL pallets may only be repaired in accordance with the technical regulations of EPAL (European Pallet Association). Only in this way can the load-bearing capacity and thus safety of the pallets be guaranteed.

Three-stage concept

At Augustinuswerk Jessen, three tons of pallet waste are processed every day: The WEIMA WL 8 single-shaft shredder is filled by forklift truck. A magnet is mounted above the discharge conveyor belt, which separates nails or the like. The wood shavings then go to a hammer mill where they are further shredded to approx. 8 mm. A WEIMA TH 1500 briquette press then presses the material into briquettes with a stable shape. These are packaged and sold at a profit.

Examples from trade and industry

Inquire about a pallet shredder today

Request a quote

No need to fear screws and nails

WEIMA shredders shred impurities such as screws, nails, metal staples and spax without any problems. Metals can be separated after shredding with an crossbelt magnet or a magnetic drum. Downstream machines such as hammermills and briquette presses are thus protected from unwanted metal debris.

WEIMA portfolio for the shredding of pallets

High throughput single-shaft shredder

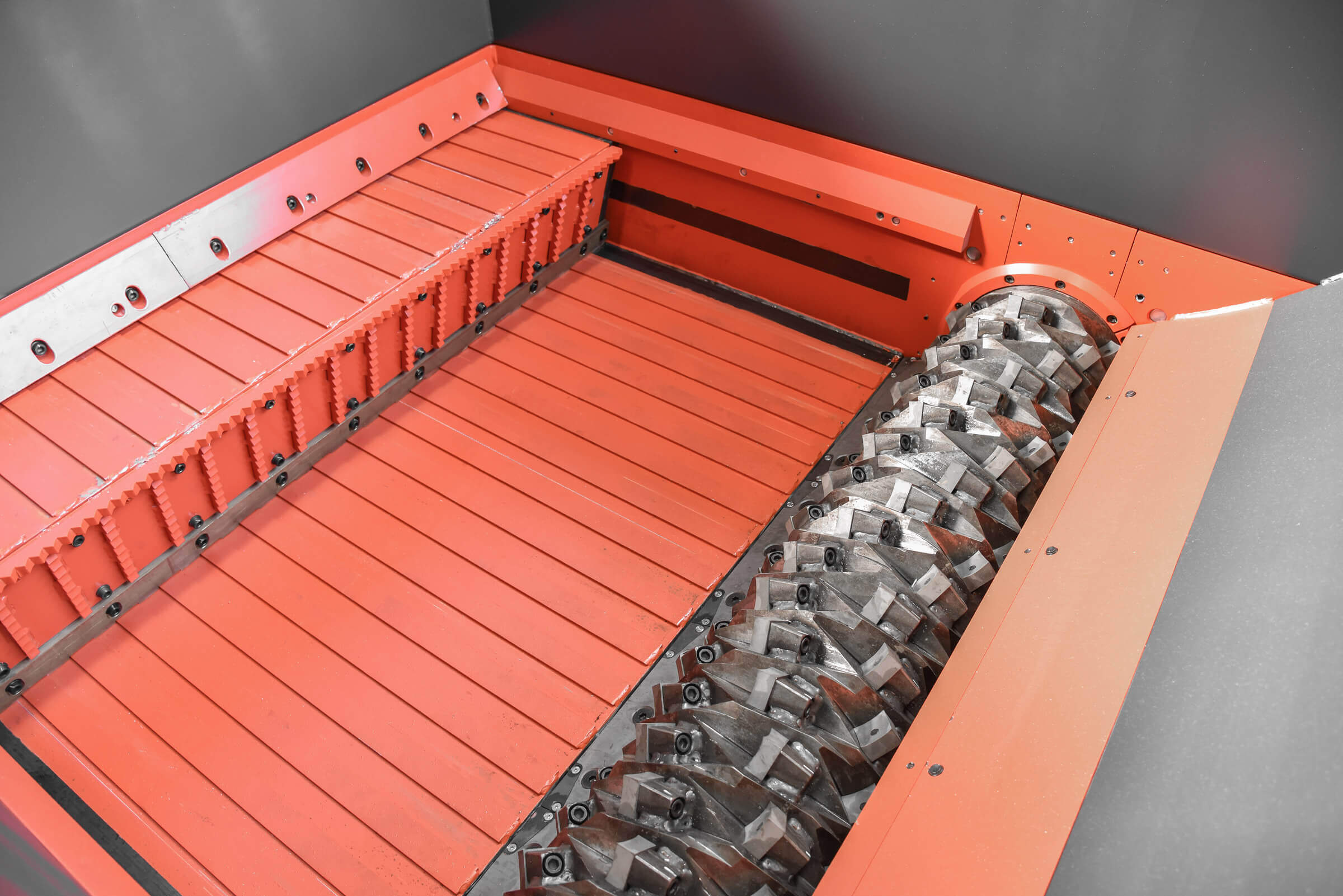

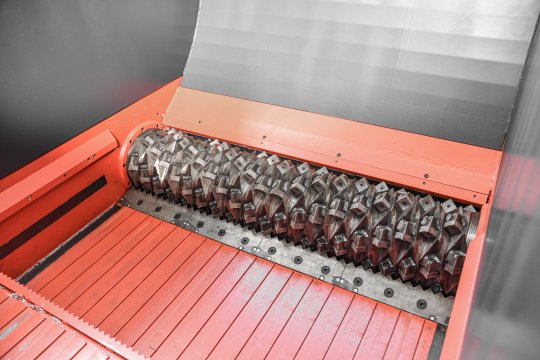

The WEIMA WLK 1500 single-shaft shredder shreds pallets without any problems on a working width of 1,500 mm.

The pallet pre-crusher

The Woodwolf was developed especially for shredding large pallets and chipboard. Using a screw conveyor, the primary crusher crushes and shreds the fed material to approx. DIN-A4 large pieces (about the size of a piece of notebook paper).

Only at WEIMA

Extremely robust machine design

for the most difficult applicationsEasy maintenance

for minimized downtimesMany drive options

for maximum throughputFast service

for highest customer satisfactionAll from one source:

Machine, conveyor system, metal detection, support, spare and wear parts

Two-stage pallet processing

A WEIMA Woodwolf breaks wood pallets roughly before a WL 10 shredder shreds the residual wood to a homogenous chip size for the subsequent heating system.

And what comes next?

Briquetting

The shredded wood chips can be compressed with WEIMA briquette presses. The briquettes can be sold profitably and are also suitable for burning in heating systems.

Burning

Wood chips can also be used directly as fuel to heat buildings and halls.The combustion of wood chips is particularly sustainable, since one uses already existing residual wood and avoids additional deforestation. The CO₂ emissions from burning wood chips are significantly lower than those from oil: approx. 28 g/kWh compared to 318 g/kWh (Source). Wood chips also make sense from an economic point of view, because they offer double savings: the disposal costs of the pallets and the acquisition costs of the additional fuel are eliminated.

Unbeatable combination: shredder and briquette press

A WEIMA WLK 1500 single-shaft shredder shreds used wooden pallets. The overband magnet separates nails and screws. The downstream TH 1500 Duo briquette press compresses the produced wood chips into strong briquettes.

See for yourself

The WEIMA show room is equipped with shredding and briquetting machines of all sizes and technologies. This enables us to simulate your application as realistically as possible. You have the possibility to send us your material or visit us directly in Ilsfeld. From our gallery you have the best view directly into the cutting chamber. So you can observe the shredding process live.

Request an appointment now

Alternatively you can send us material for testing.

Click here for the form.

Newsletter

Sign-up for our newsletter today.

Sign-up for our newsletter