Pulper Rope Shredding

Ragger wire processing – cut disposal costs and reclaim steel

The use of waste paper in paper production is constantly increasing. In Germany alone, around five million tons of recyclable residues are produced every year, mostly in the form of pulper ropes made of metal and plastic or loose spit materials.

These so-called pulper rejects require specialized shredding technology in order to recover valuable materials such as plastic (as a substitute fuel) or metals such as steel, copper and aluminium. Without prior processing, disposal is associated with high costs for paper manufacturers.

Customer applications: Pulper rope recycling with WEIMA

Practical examples of successful shredding with WEIMA shredders

Want to tackle your waste problem?

Request a customized shredding solution now.

WEIMA portfolio for shredding pulper ropes

The right machine for every material

Example applications from the secondary fuel industry and paper production

Inquire about a pulper shredder today

Request a quote

Recycling of pulper ropes

Key facts at a glance

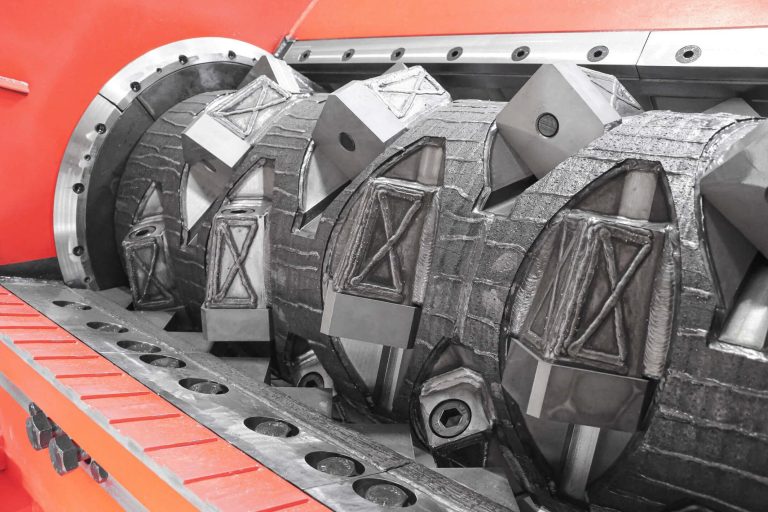

Heavy duty machine design

WEIMA shredders for highly abrasive materials can be equipped with numerous options to protect against wear – for less downtime and lower maintenance costs. The solid machine frame ensures particular robustness. Rotors can be reinforced with Vautid and screens with Creusabro. Optionally, large knives (up to 130 x 130 mm) protect against foreign bodies, Vautid can also secure knife carriers.

To protect the rotor face plates, we recommend replaceable Creusabro wear plates that can be fitted on both sides. The cutting chamber can also be optionally reinforced with replaceable Creusabro plates. For particularly heavy-duty applications, we offer an approx. 20 mm thick, wear-resistant Creusabro screen.

Did you know?

In Germany, an average of 760 kg of recovered paper was used to produce one ton of paper in 2018. Tendency: rising.

Convince yourself.

Have your material tested free of charge in our test center.

Frequently Asked Questions about Pulper Rope Shredding

Everything you need to know about safely and efficiently shredding pulper ropes.

What are pulper ropes and why do they need to be shredded?

Pulper ropes, also known as ragger tails, are tangled reject materials removed from paper pulpers. They typically consist of plastics, fibers, textiles, and steel wire, forming long, dense bundles that are difficult to handle. Shredding reduces these ropes into manageable pieces, significantly lowering volume and improving handling. This size reduction also enables efficient separation of metals and prepares the remaining material for energy recovery or further processing.

How does pulper rope shredding work from intake to discharge?

Pulper ropes are fed into a heavy-duty WEIMA shredder via conveyor, grab, or manual loading, depending on plant layout. Inside the shredder, a robust rotor and counter knives cut the ropes into smaller pieces, while a screen defines the output size. The shredded material is then discharged onto a conveyor and routed through magnetic separation to remove steel wire. The remaining non-metal fraction is sent to the appropriate downstream process.

What happens to the material after pulper rope shredding?

After shredding, ferrous metals are removed using magnetic separation and sent for recycling. Additional separation steps can be added if cleaner fractions are required. The remaining non-metal material is typically routed to energy recovery or another approved processing route, depending on local permits and plant strategy. Shredding ensures the material is in a suitable form for these downstream uses.

Can a WEIMA shredder handle steel wire in pulper ropes?

Yes. WEIMA shredders are designed for contaminated materials such as pulper ropes containing steel wire. The shredding step breaks up the tangled structure so that ferrous metals can be reliably removed by magnets after size reduction. This approach minimizes manual handling, protects downstream equipment, and improves the purity of both the metal and non-metal fractions. Effective metal separation is a key benefit of controlled shredding.

What output size is recommended for shredding pulper ropes?

The optimal output size depends on downstream requirements, but most operations choose a medium, consistent particle size that conveys easily and supports effective metal separation. The screen installed in the shredder primarily determines this size. Smaller pieces improve separation efficiency, while slightly larger pieces may reduce wear and energy consumption. The final choice should align with whether the non-metal fraction is used for energy recovery, storage, or further processing.

Do pulper ropes require a single shredder or a two-stage setup?

Both single-stage and two-stage configurations are used in practice. Very thick, wet, or heavily compacted ropes may benefit from a two-step approach to ensure stable operation and consistent throughput. In other cases, a single heavy-duty shredder is sufficient. The decision depends on rope condition, throughput targets, desired output size, and how uptime, wear, and energy use are balanced.

How are wet and dirty pulper ropes processed without frequent jams?

WEIMA systems are designed to handle wet and contaminated material, but stable operation relies on good process discipline. Allowing excess water to drain before feeding, keeping the infeed area clear, and monitoring wear parts help prevent blockages. Operators should be trained to identify unshreddable objects before they enter the cutting chamber. Regular inspections and housekeeping significantly reduce unplanned stoppages.

What does maintenance look like?

Routine maintenance focuses on inspecting knives, counter knives, and screens, as well as keeping the infeed area clean. Operators should watch machine load indicators for changes that signal wear or blockages. Planned service intervals for wear part replacement and clearance adjustments help maintain high uptime and consistent performance.

What are you looking for?

Explore all WEIMA solutions