HDPE Pipe Shredding for Sustainable Plastic Pipe Recycling

WEIMA HDPE shredders enable efficient plastic pipe recycling – ideal for pipe producers and recyclers

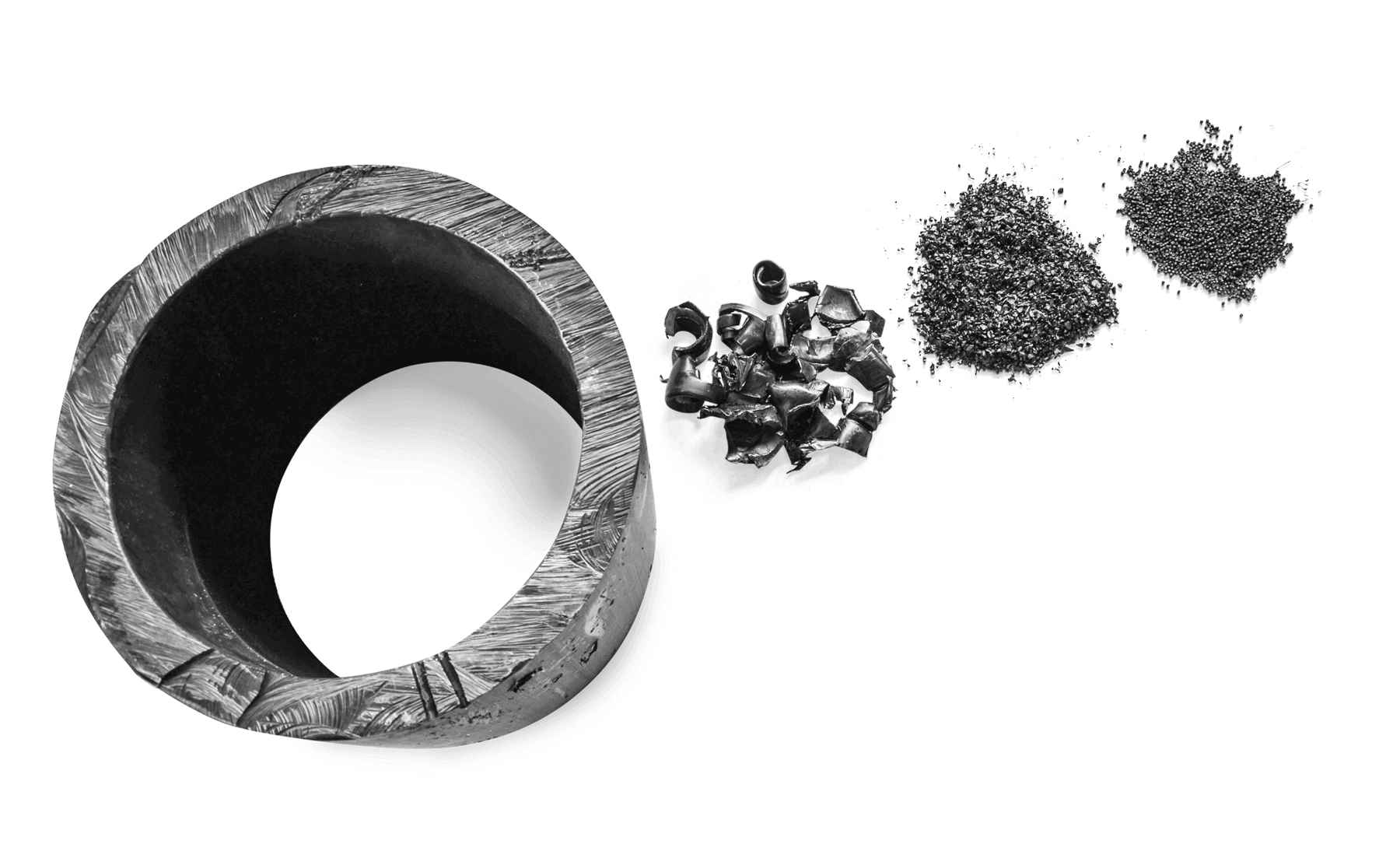

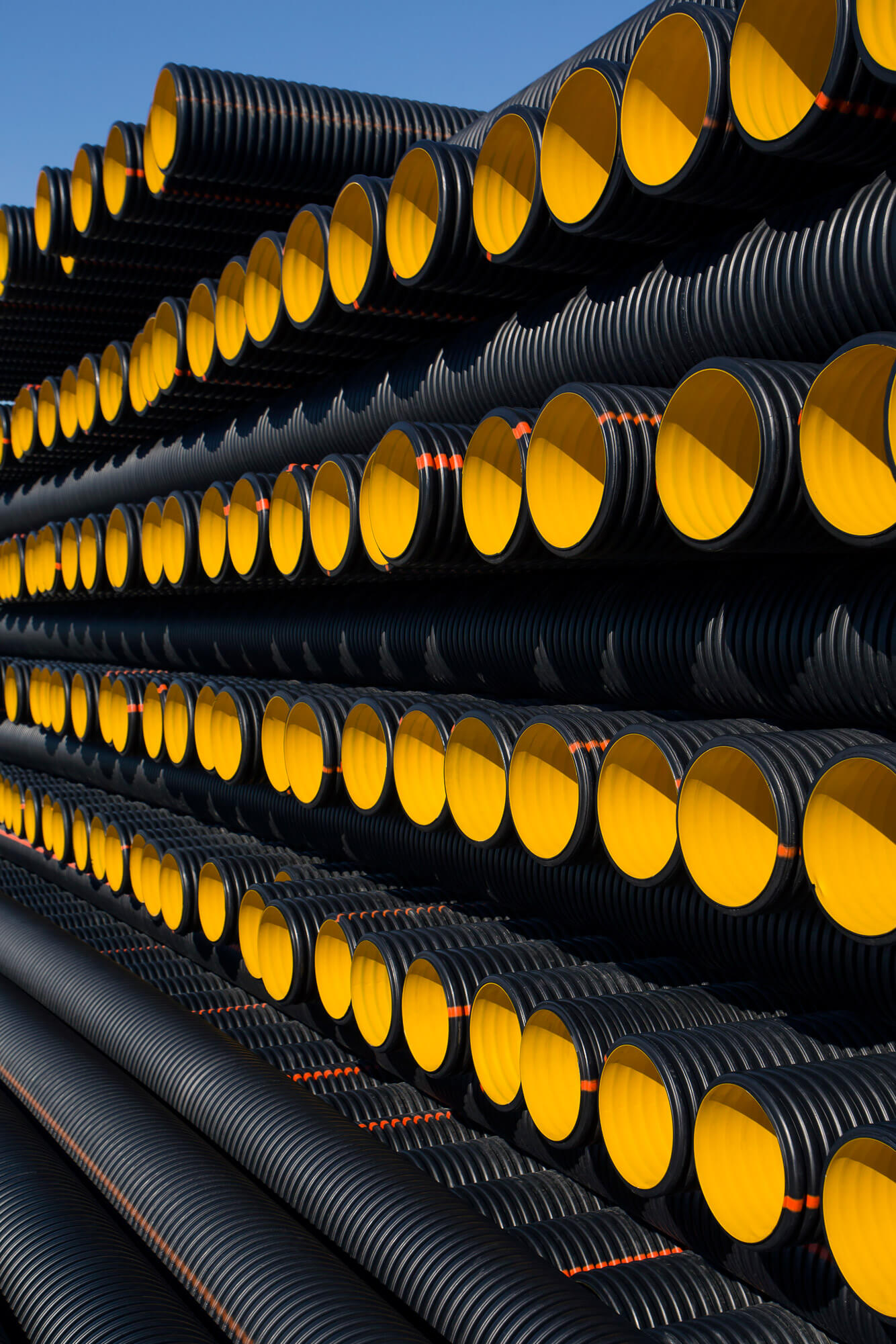

HDPE plastic pipes are extremely durable and are used worldwide for water supply, gas pipelines, and cable protection. However, large volumes of HDPE pipe waste are generated both during production and after use. For sustainable recycling, professional shredding is essential. With powerful shredders from WEIMA, HDPE pipes are efficiently reduced to manageable pieces. This allows the material to be easily cleaned, recycled, and reprocessed into high-quality regranulate – making an important contribution to the circular economy and reducing plastic waste.

Customer applications: Plastic pipe shredding with WEIMA

Practical examples of successful shredding with WEIMA shredders

Want to tackle your waste problem?

Request a customized shredding solution now.

WEIMA portfolio for shredding plastic pipes made of HDPE, PP, PE and PVC

The right machine for every material

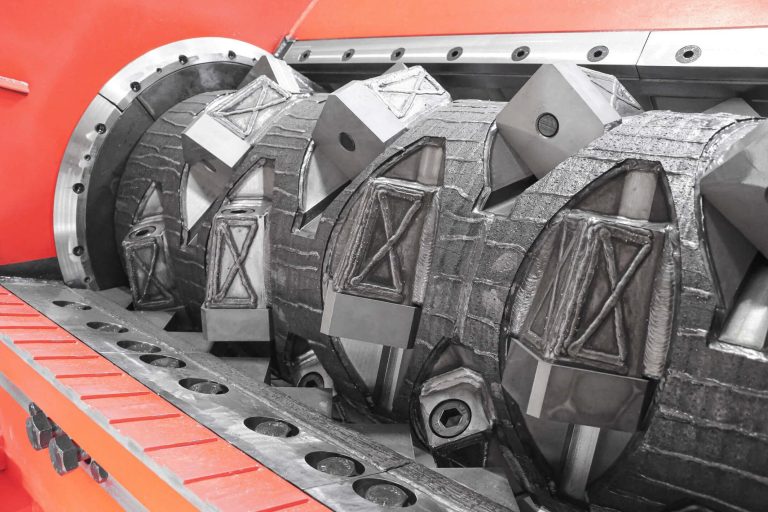

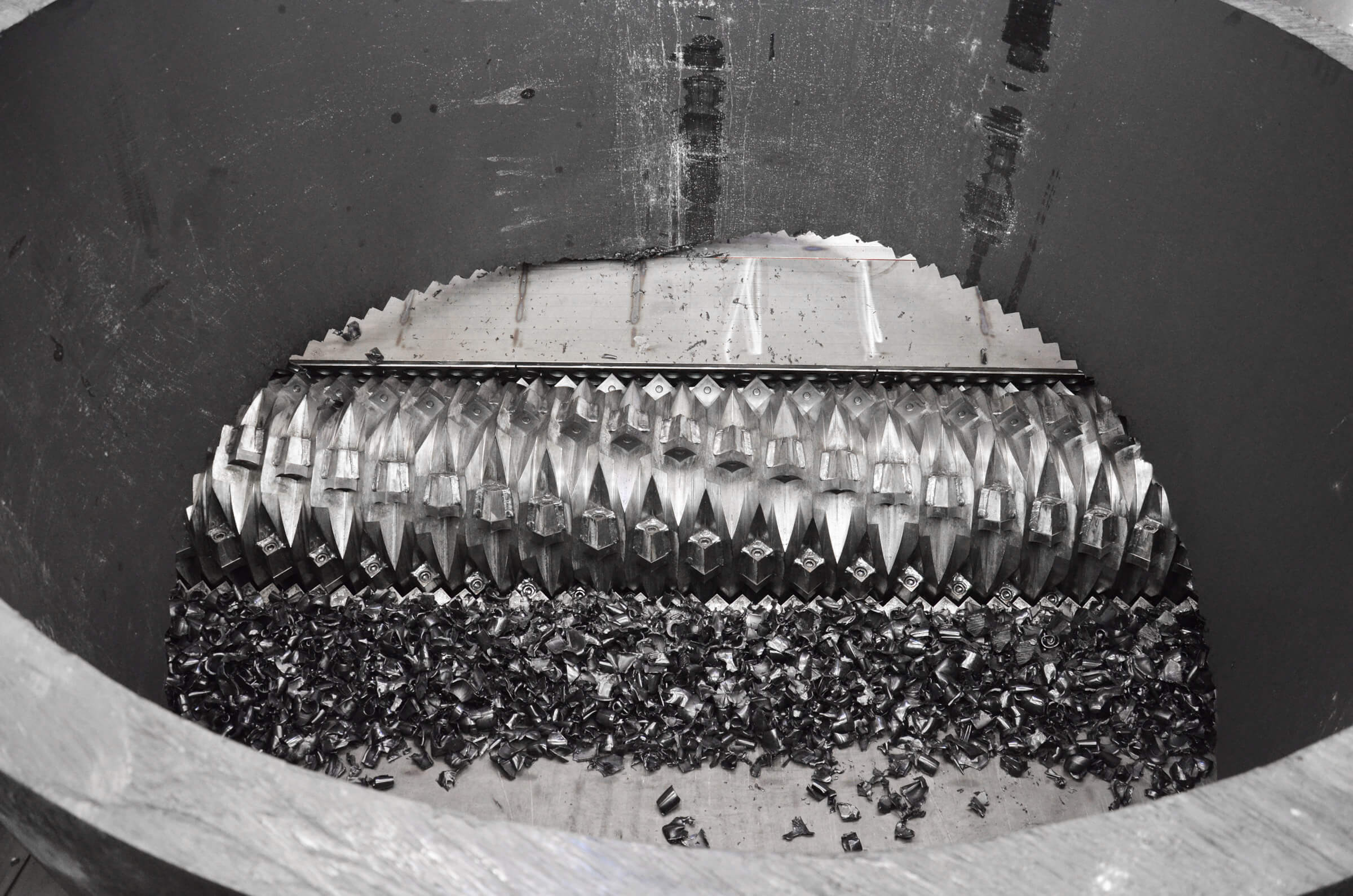

Heavy duty machine design against increased wear

WEIMA shredders for processing highly abrasive materials can be protected with various options to reduce wear and thus downtime and maintenance costs. The thick walls of the machine frame make WEIMA shredders particularly robust.

Example applications from industrial plastic pipe manufacturing

Inquire about a plastic pipe shredder today

Request a quote

Recycling plastic pipes made of HDPE, PP, PE and PVC

The most important facts at a glance

Did you know?

In 2017, nearly 800,000 tons of plastic pipe systems were produced in Germany.

See for yourself.

Have your material tested free of charge in our test center.

Frequently Asked Questions about HDPE pipe Shredding

Everything you need to know about safely and efficiently shredding HDPE pipes.

Can we feed long pipe sections or coils without pre-cutting?

In many cases, yes — with the right hopper design and feeding method. Single-shaft shredders pull in the material with a rotor and counter-knives, while large hoppers handle long sections and nested pipe coils. WEIMA WLK 1000 and WLK 1500 systems at Palaplast, as well as PowerLine 2500 lines in Sweden, demonstrate that even long HDPE pipes can be processed without cutting.

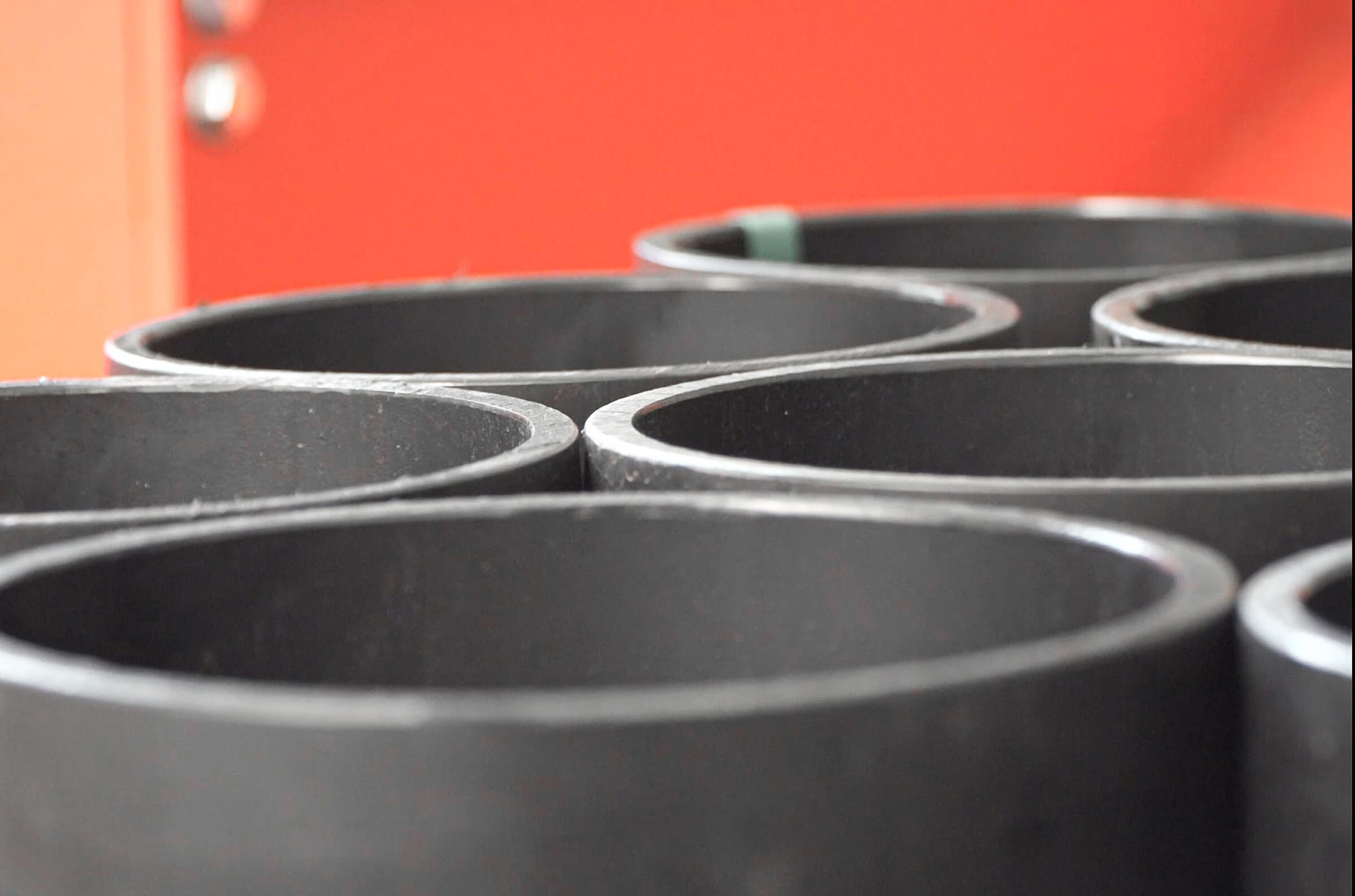

Can your shredder handle large-diameter HDPE pipes?

Yes. Single-shaft shredders like the WEIMA PowerLine 2500 are engineered for thick-walled HDPE pipes, bulky extrusion scrap, and heavy start-up lumps. The system uses a high-mass rotor, robust wear protection, and oversized hoppers that reliably grip long sections and irregular shapes. Knife geometry, screen size, and drive options can be customised to deliver a consistent cut across varying material types.

What happens to the shredded pipe after it leaves the shredder?

Typically, the shredded material is cleaned, then fed into an extruder to produce high-quality regranulate. The resulting regranulate can be blended back into pipe production alongside virgin material. This is the established mechanical recycling route for PE and PP pipe systems.

We run HDPE today. Can the same shredder also process PP, PE, or PVC pipes?

Yes. The same WEIMA shredder platform can process HDPE, PP, PE, and PVC with the appropriate machine configuration. If you run filled, mineral-reinforced, or abrasive pipes, adding wear liners and hardened components reduces maintenance and extends machine life.

How clean should our pipe scrap be before shredding?

Cleaner material improves output quality, but typical post-industrial scrap can usually be processed without pre-cleaning. Post-consumer pipes benefit from sorting and washing to remove metal parts, soil, and stones that could damage the cutting chamber. After basic cleaning, WEIMA shredders produce homogeneous regrind suitable for extrusion into new pipes. This ensures consistent regranulate and protects downstream equipment.

What maintenance should we plan for a shredder that processes pipes?

Set a routine that includes regular knife inspections, scheduled knife rotations or replacements, and checks on wear liners in high-impact zones. Inspect screens for blockage or fatigue and keep lubrication schedules consistent. Maintain good housekeeping around the machine to avoid slip hazards and ensure safe operation. Keeping essential wear parts in stock helps minimise downtime and ensures continuous, reliable shredding performance.

What are you looking for?

Explore all WEIMA solutions