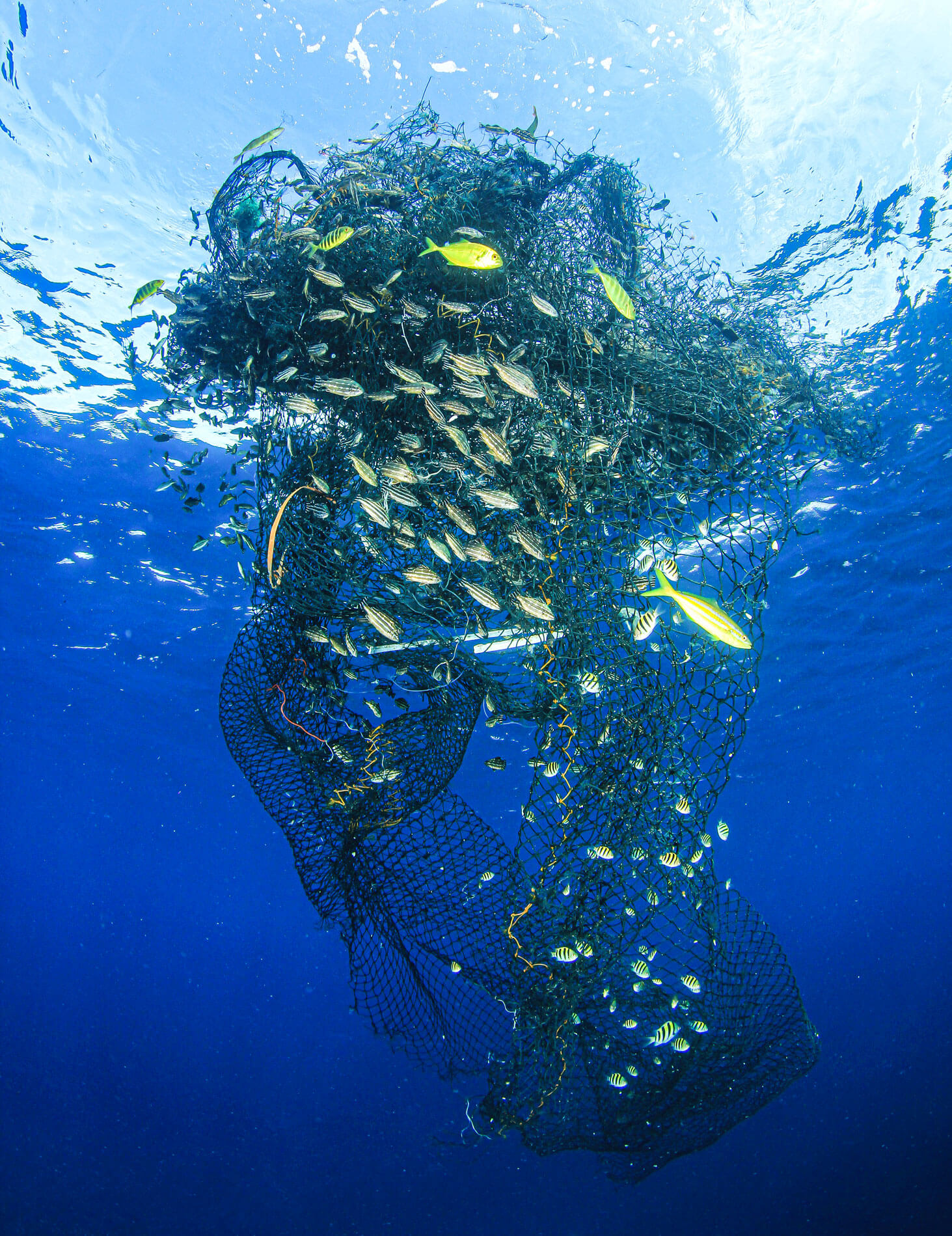

Shredding & Recycling of Old Fishing Nets (Ghost Nets)

Sustainable shredder solutions for abandoned fishing nets and ropes – turn ghost nets into reusable raw material

While fishing nets are an important tool for fisheries, they also pose a major threat to the marine environment. Every year, many tons of fishing nets end up in the oceans, where they become a serious threat to marine life. But there is hope: recycling fishing nets offers a sustainable solution to address this problem and recover valuable resources.

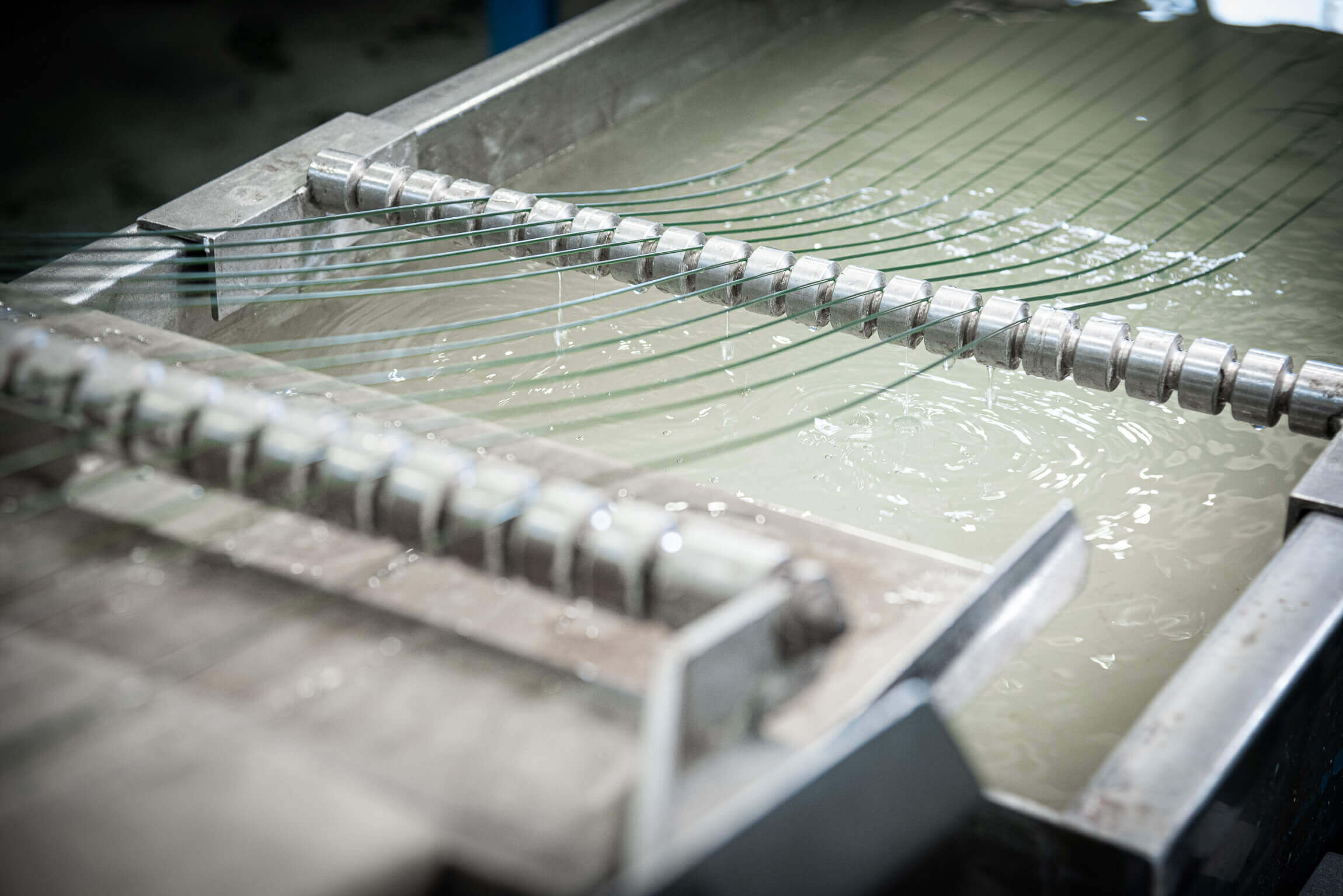

Through the targeted use of industrial shredders, old fishing nets and ropes can be effectively shredded and prepared for the further recycling process. The plastic flakes obtained are washed, melted and processed into high-quality regranulate – a valuable raw material for new products. This turns marine waste into a recycled material that protects both the environment and resources.

Customer applications: Fishing net shredding with WEIMA

Practical examples of successful shredding with WEIMA shredders

Want to tackle your waste problem?

Request a customized shredding solution now.

WEIMA portfolio for shredding fishing nets

The right machine for every material

Example applications for the sustainable disposal of fishing nets

Request now the right shredder for plastic fishing nets

Request quote

Designed for fibers such as fishing nets: The F-Rotor

The optimum coordination of rotor, blade and counter blade is crucial for the shredding result. Choosing the right components for the material requires a great deal of experience. The F rotor, specially designed for fibres, is characterized by its controlled feed behaviour.

By the way: For particularly abrasive or contaminated materials, we recommend a wear protection jacket made of Vautid.

WEIMA F rotor for flexible material

Recycling of fishing nets

The most important facts at a glance

Did you know?

Greenpeace estimates that every year about 30 million tons of so-called bycatch are produced, which often die in agony in nets.

See for yourself.

Have your material tested free of charge in our test center.

Frequently Asked Questions about Fishing Net Shredding

Everything you need to know about safely and efficiently shredding fisher nets.

How does a fishing net shredder work?

A fishing net shredder reduces nets into uniform Flakes that are easier to clean and recycle. Inside the machine, a single rotating shaft equipped with knives pulls the nets in and shears them against a counter knife. A screen beneath the rotor retains the material until it reaches the defined size. This controlled size reduction lowers volume, improves handling, supports dirt removal, and prepares the plastic for washing, melting, and pelletizing.

Do fishing nets need to be pre-cleaned before shredding?

Perfect cleanliness is not required, but basic pre-sorting is recommended. Large metal parts, stones, or thick steel cables should be removed to protect the rotor and knives. Typical components such as floats, knots, and rope sections can be processed without issue. Light dirt and moisture are acceptable, as washing usually follows shredding. Proper pre-sorting helps extend tool life and maintain stable uptime.

Can the shredder handle wet, sandy, or salty fishing nets?

Yes, wet and salty nets can be shredded without issue. The main challenge is abrasive contaminants such as sand, stones, or metal fragments, which can accelerate wear. Removing heavy grit before shredding helps protect knives and bearings and keeps uptime high. Many recycling lines include washing and separation steps after shredding to remove remaining impurities and stabilize material flow.

Is this setup suitable for nylon and polypropylene fishing nets?

Yes. WEIMA single-shaft shredders are designed for common fishing-net polymers such as nylon (PA) and polypropylene (PP), including mixed rope and net structures. Models like the WLK 1500 and the W5 series are proven in fiber-based applications. The W5.22, with its hydraulic drive, is particularly well suited for tough pulls and uneven material loads. For very dense bundles or thick ropes, a larger hopper or a pre-shredding step can improve feeding consistency.

What happens after the fishing nets are shredded?

After shredding, the Flakes are typically washed, dried, melted, and extruded. Washing removes salt, sand, and organic residues, while drying prepares the material for extrusion. The clean Flakes are then melted and pelletized into regranulate. This mechanical recycling route is the standard process for recovering plastics from fishing nets and similar gear.

What is the difference between the WLK 1500 and the W5.22 for fishing nets?

Both machines are suitable for fishing nets, but they address different operating conditions. The WLK 1500 is a proven single-shaft shredder for fiber residues and nets, delivering consistent Flake size through a screen-based system. The W5.22 features a hydraulic drive, allowing it to start and reverse under load, which is advantageous for heavy ropes, knots, and irregular feeding. The best choice depends on material mix, required throughput, desired Flake size, and feed consistency.

What are you looking for?

Explore all WEIMA solutions