Shredding & Recycling Plastic Purge Lumps from Injection Molding & Extrusion

Start-up Scrap Recycling: Turn Purge Waste into Valuable Regrind

One of the most common material applications of plastics shredding is the processing of so-called plastic lumps, which are usually generated as a waste product during the extrusion of plastics. The economic potential of this "purge" is enormous. It is expensive to dispose of the unused purge lumps. Recycling offers the possibility of seamlessly reintegrating production scrap into the manufacturing process instead of using new resources.

Customer applications: Plastic lumps and purgings shredding with WEIMA

Practical examples of successful shredding with WEIMA shredders

Want to tackle your waste problem?

Request a customized shredding solution now.

WEIMA portfolio for shredding plastic lumps and purgings

The right machine for any material

Applications from industrial plastics production

Recycling of plastic lumps

Key facts at a glance

Inquire about a plastics lump shredder today

Request a quote

Did you know?

Thermoplastics are plastics that, unlike thermosets and elastomers, can be formed as often as required - as long as they are not overheated, otherwise they may decompose. Well-known thermoplastics include polypropylene (PP), polycarbonate (PC), polyamide (PA), polyethylene (PE), polystyrene (PS), polyvinyl chloride (PVC) and acrylonitrile butadiene styrene (ABS).

Heavy duty machine design

WEIMA shredders are engineered to handle highly abrasive materials and can be individually equipped with wear-reducing options. Thanks to the thick-walled machine frame, they operate with exceptional stability and long service life – even when processing tough plastic purgings. This significantly reduces downtime and sustainably lowers maintenance costs.

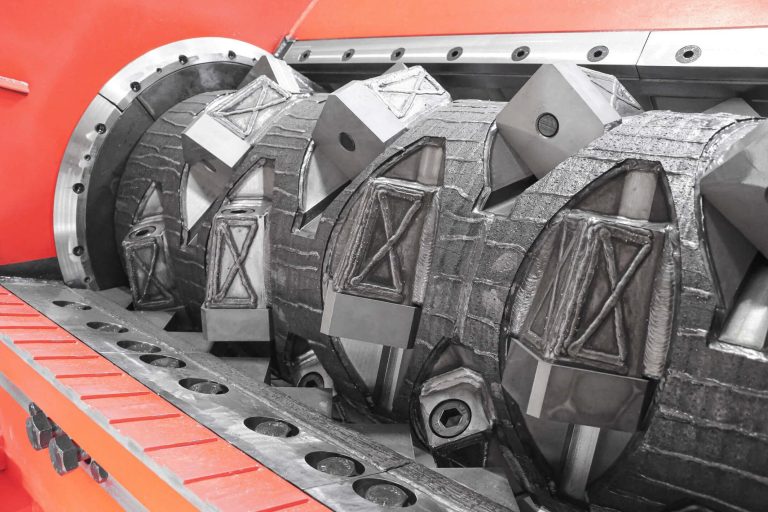

Precise cutting at high throughput with profiled V-rotor

The V-rotor, specially developed by WEIMA, can be used universally and is made from solid material. Its aggressive material feed with up to two rows of blades guarantees a high throughput with low power requirements. It can be fitted with hardened steel cutting blades in edge lengths of 30 mm and 40 mm. These can be reversed several times when worn, which drastically reduces maintenance costs.

Profiled V-Rotor with counter knives

Convince yourself.

Shred your material on our machines now.

Frequently Asked Questions about Plastic Lump Shredding

Everything you need to know about safely and efficiently shredding plastic purgins.

Which WEIMA machine is best for shredding large plastic lumps and blocks?

For large and heavy start-up lumps we recommend a robust single-shaft shredder from WEIMA’s W5 or S7 series. These machines are built with reinforced frames, heavy-duty rotors and large intake openings to handle massive volumes of hard plastics like HDPE or PP. With the right geometry they deliver a steady throughput and create a homogeneous output for recycling.

How does the shredding process work for start-up lumps?

First, the lumps are fed into the shredder (e.g., WEIMA W5.22 or S7.20) which breaks them down mechanically into smaller flakes. Then optional separation units (e.g., magnets) remove metal parts or contaminants. The resulting material is uniform, clean and ready for re-granulation or reuse, closing the loop in the production chain.

Can other production waste be processed together with start-up lumps?

Yes. Our shredders can shred not only start-up lumps, but also thick-walled molded parts, production rejects, or plastic sheets. The key is choosing the right machine—WEIMA will help you configure your system to achieve maximum efficiency and material purity.

What are the economic benefits of recycling these lumps instead of disposing them?

By shredding start-up lumps you transform what was once costly scrap into a valuable secondary raw material. Disposal fees drop, shipping and storage costs shrink and you reduce your dependence on expensive virgin resin. Many WEIMA customers report rapid pay-back periods by reintroducing shredded material into their production.

Which materials and processes are suitable for this type of shredding?

Start-up lumps from extrusion and injection moulding of thermoplastics such as PP, PE, ABS, PC, PA and similar are particularly suitable. WEIMA machines handle flexible and rigid plastics alike and can be integrated into lines with automatic feeders, conveyors and downstream granulators. Even blocks with heavy contamination or irregular geometry can be processed with the right machine configuration.

What about wear, maintenance and machine robustness in these high-stress applications?

WEIMA shredders for these applications are equipped with thick steel frames, wear-protected cutting tools (e.g., Vautid steel) and high‐torque drives designed for continuous operation. Maintenance is simplified through features like large inspection doors and quick‐change knives. Properly set up, downtime is minimal and operational reliability high.

How do we select the right machine size and configuration for our production line?

The selection depends on purge size, material type, throughput requirement and available floor space. WEIMA recommends submitting sample lumps for a free test in our technikum, so you can see actual performance and output characteristics. From there, we propose a customised solution including shredder size, feed conveyor, separator and downstream equipment.

What are you looking for?

Explore all WEIMA solutions