Shredding and Recycling Rigid Plastics

Efficient solutions for post-consumer and industrial hard plastic recycling

Rigid plastics are so-called non-packaging plastics that are manufactured using various thermoforming processes. These include products such as buckets, watering cans, flower pots, pasta strainers, garden furniture and laundry baskets, which are used in private households. However, industry also uses hard plastics such as plastic pallets, waste containers, waste garbage cans and pipes.

Used hard plastics often end up in residual waste or are incinerated - their recycling potential is lost. The sustainable alternative is the professional recycling of post-consumer and industrial waste. The first step: shredding with WEIMA shredders to produce high-quality recyclate, which serves as a raw material for new plastic products.

Customer applications: Rigid plastics shredding with WEIMA

Practical examples of successful shredding with WEIMA shredders

Want to tackle your waste problem?

Request a customized shredding solution now.

WEIMA portfolio for shredding rigid plastics

The right machine for every material

Heavy duty machine design against increased wear

WEIMA shredders for processing highly abrasive materials can be protected with various options to reduce wear and thus downtime and maintenance costs. The thick walls of the machine frame make WEIMA shredders particularly robust. The rotor can be reinforced with Vautid, the screen with Creusabro. In order to protect the cutting knives against the impact of foreign objects, large knives with an edge length of up to 130 mm x 130 mm can be selected. Vautid can also protect knife carriers.

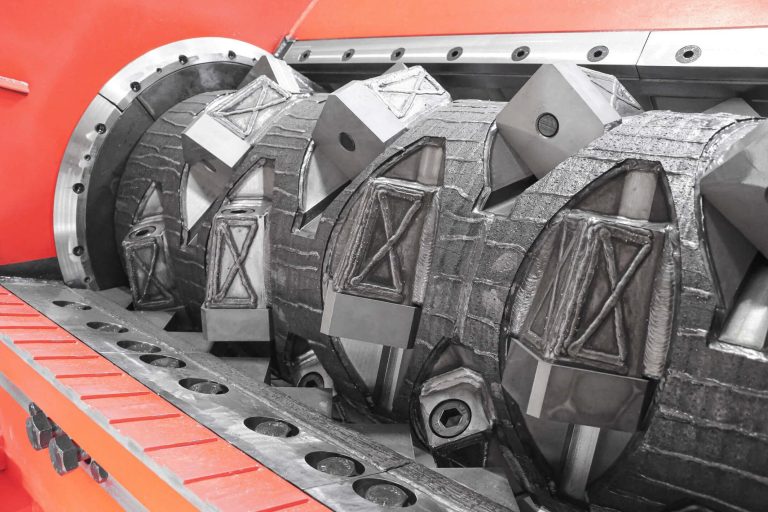

Best suited for hard plastics – the V rotor

The V rotor, specially developed by WEIMA, can be used universally and is made of solid material. Its aggressive material feed guarantees high throughput with low power requirements. Hardened steel cutting knives and adjustable counter-knives ensure the optimum cutting geometry, which can be precisely adapted to the material requirements. The result: homogeneous shredding results, high throughput rates, low energy consumption, resistance to foreign material, and low wear.

WEIMA V-rotor shreds HDPE pipes

Applications for the sustainable disposal of hard plastics from industry and private households

Inquire about a rigid plastics shredder today

Request a quote

Recycling of rigid plastics

The most important facts at a glance

Did you know?

Throughout Germany, nearly 3 million tons of plastic are recycled each year. From this, about 1.9 million tons of recyclate can be produced after the removal of impurities and color sorting.

Source: German Federal Ministry for the Environment, Nature Conservation and Nuclear Safety

See for yourself.

Have your material tested free of charge in our test center.

Frequently Asked Questions about rigid plastics shredding

Everything you need to know about safely and efficiently shredding rigid plastics.

Which rigid plastics can these machines handle?

WEIMA shredders can process nearly all common rigid plastics found in bins, crates, pipes, profiles, technical parts, and housings. Typical materials include PE, HDPE, PP, PS, PET, PA, PC, ABS, and PVC, each of which responds well to a correctly configured single-shaft shredder. On this page you’ll see PVC and vinyl shredded on a WLK 4, as well as HDPE bins processed on a PowerLine 2500. Knife style, rotor geometry, and screen size should always match your polymer mix and required flake size.

We process a lot of HDPE bins. Which shredder setup should we look at?

For high volumes of HDPE, a robust single-shaft shredder like the PowerLine 2500 or a WLK model with the right screen is a strong choice. These machines deliver stable torque and consistent flake quality, even with bulky or tough material. Hydraulic drives can be beneficial when load conditions vary significantly. The page highlights PowerLine 2500 running post-consumer HDPE bins and the WLK 1500 improving storage and transport efficiency for mixed rigid plastics. Match your screen size, infeed conveyor, and metal separation to your washing and extrusion requirements for a stable line.

How clean does the plastic need to be before shredding?

It is not necessary for the material to be perfectly clean. WEIMA shredders are engineered to process moderately contaminated plastics and can reliably handle the typical dirt, dust, and surface residues found in both post-consumer and post-industrial streams. Nevertheless, removing stones, large metal parts, and other heavy contaminants is recommended to protect critical components such as knives, screens, and bearings. After shredding, established washing and separation processes remove remaining dirt, labels, and fines to prepare the flakes for further processing. Proper pre-sorting not only extends the service life of wear parts but also ensures stable throughput and consistent output quality.

How often do knives and wear parts need attention?

Maintenance frequency depends on material type and contamination levels, but regular checks are essential. Perform quick visual inspections every shift and schedule weekly knife and screen reviews. Abrasive materials or dirtier input streams may require more frequent knife rotations. WEIMA shredders use heavy frames and wear protection to extend component life, but a simple maintenance plan and readily available spare parts ensure consistently high uptime.

What happens after the material is shredded?

Shredded material is typically washed, separated, and then pelletized into regranulate for reuse. A standard process sends flakes from the shredder to a wash plant, then uses density separation (e.g., sink-float) and metal separation to clean and sort the polymers. Once contaminants are removed, clean flakes move to an extruder where they are melted and pelletized. These pellets can then be reused for new products, including rigid packaging, bins, and technical parts. Properly configured sink-float systems achieve high polymer recovery rates.

What screen size should I use and how does it affect the output?

The screen determines how coarse or fine your flakes will be. Smaller holes create finer flakes but reduce throughput, while larger holes increase capacity but produce coarser output. Choose a screen that supports your washing efficiency, extrusion stability, and end-product specifications. Finer flakes often wash and melt more uniformly, while coarser flakes may be perfectly adequate for many rigid plastic applications. Test runs with your actual material mix help identify the optimal size.

How do these machines help with storage and transport?

Shredding significantly reduces volume and produces uniform flakes that are easier to store, bale, silo, or load into big bags. A consistent flake size also stabilizes downstream processes like washing and extrusion. The WLK 1500 shown on this page demonstrates how size reduction can improve handling efficiency across the value chain. Uniform material flow helps minimize bottlenecks and reduces logistical effort.

What are you looking for?

Explore all WEIMA solutions