Shred & Recycle Wooden Pallets – Save Space and Cut Costs

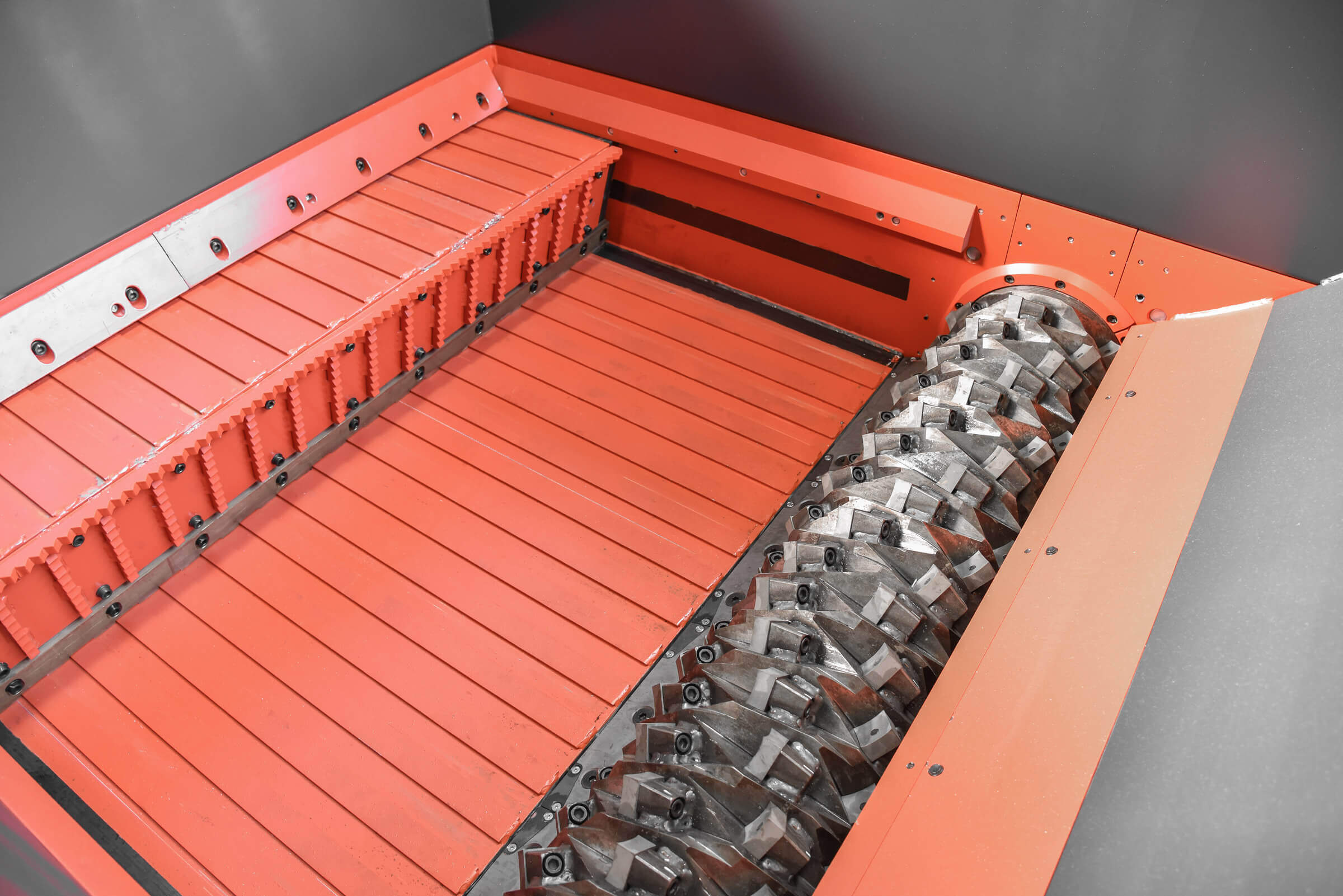

Industrial pallet shredders quickly reduce bulky pallets into small, manageable pieces

Pallets, also called transport pallets, are used globally for the safe transport and storage of stackable goods. There are different materials from which pallets are made: for example wood, plastic, corrugated cardboard and sheet metal. The most common are pallets made of wood. Disposable pallets are usually made of cheap softwoods – the boards and squared timber are simply nailed or screwed together. One of the best known is the euro-pallet with standardized dimensions and materials. WEIMA offers suitable shredding machines for all types of pallets.

Customer applications: Pallet shredding with WEIMA

Practical examples of successful pallet processing with WEIMA chippers.

Want to tackle your waste problem?

Request a customized shredding solution now.

WEIMA portfolio for the shredding of pallets

Two powerful machines for every type of pallet

Examples from trade and industry

Inquire about a pallet shredder today

Request a quote

Shredding and recycling of pallets

The most important facts at a glance

Pallet types

- Pallet made of solid wood, e.g. one-way pallet, euro-pallet

sustainable, very resilient, easy to repair - Pallet made of pressed wood, e.g. INKA or chipboard pallet

environmentally friendly, light, nestable/stackablebr - Pallet made of plastic, e.g. hygienic pallet, clean room pallet

low weight, durable, hygienically advantageous - Pallet made of corrugated cardboard, e.g. light pallet

recyclable, low weight, environmentally friendly

Pallets are available in different materials and in various shapes/sizes. Each of them has its own right to exist and has specific advantages and disadvantages, depending on the application.

All pallets have one thing in common:

WEIMA shredders shred them.

See for yourself.

Have your material tested free of charge in our showroom.

Frequently Asked Questions about Pallet Shredding

Everything you need to know about safely and efficiently shredding wooden pallets.

How can I safely and efficiently shred old pallets with nails?

For pallets containing nails, screws, or metal fittings, a robust single-shaft shredder such as the WEIMA WLK 1500 is ideal. Its solid construction and powerful drive allow it to process foreign materials without interruption. Even damaged or filled pallets can be reliably shredded into uniform wood pieces – safely, efficiently, and with minimal maintenance.

What happens to the wood chips after pallet shredding?

The resulting wood chips can be used in many ways – for example, as fuel for heating systems or as feedstock for briquetting. Many companies combine a WEIMA shredder with a briquetting press to turn wood waste into compact, energy-rich fuel briquettes. In this way, waste wood becomes a valuable and sustainable resource.

How can we reclaim storage space when old pallets pile up?

An industrial shredder like the WLK 1500 allows bulky pallets to be shredded directly on site into manageable pieces. This reduces the volume by up to 90% and frees up valuable storage space. The processed material can then be easily stored, transported, or reused – a major advantage for companies with large pallet quantities.

Is a pre-shredder necessary?

For particularly bulky or high-volume pallet stacks, a pre-shredder such as the Woodwolf is recommended. It performs coarse shredding and prepares the material for a downstream shredder like the WLK 1500. This setup protects the main machine, minimizes wear, and ensures a consistent material flow.

Can shredded pallets really help us save on heating costs?

Yes. Shredded pallet wood can be used directly or after briquetting as an efficient fuel source. Many WEIMA customers heat their workshops or warehouses with this material, significantly reducing energy expenses. It eliminates costly disposal and provides both economic and environmental benefits.

What can I do with leftover wood from pallet processing instead of paying for disposal?

By shredding and briquetting, leftover pallet wood can be turned into high-quality fuel or recyclable material. These products can be used internally or sold for profit. This transforms waste into value while cutting disposal and energy costs.

How does the shredding process work with WEIMA machines?

Pallets are mechanically shredded by a rotor equipped with knives, as in the WEIMA WLK 1500. Optional magnetic separators then remove metal contaminants such as nails or screws from the wood chips. The cleaned material can be used directly for energy generation or further processed downstream.

How durable are WEIMA shredders in continuous operation with nails and metal parts?

WEIMA shredders like the WLK 1500 are engineered for continuous industrial use. A heavy-duty steel frame, hardened cutting tools, and a powerful drive system ensure maximum durability. Even pallets containing nails, screws, or metal fasteners are processed safely and without interruption.

How much space does the machine require?

The required space depends on the specific shredder model and system configuration. WEIMA designs every solution individually, including feeding, conveying, and discharge systems. The result is a space-efficient setup perfectly tailored to your facility layout.

What are you looking for?

Explore all WEIMA solutions