Municipal Solid Waste (MSW) Shredders

Durable industrial shredders for household waste and municipal waste recycling

Residual waste from private households or similar places is anything but just waste – in most cases it's a veritable goldmine of recyclable materials. In Germany alone, more than 50 million tons of municipal waste are generated every year. Waste collection services collect more than 13 million tons of household waste, which still contains high proportions of plastics and paper, even though these materials should be disposed of separately. Particularly robust machines are required for the subsequent processing of all material fractions, as municipal waste is usually full of foreign materials such as stones and metals. WEIMA offers the right shredders for this first process step, shredding, with working widths of up to three meters, many heavy duty options and drive concepts specially designed for these applications. The result: safely and cleanly processed, homogeneous material streams.

Customer applications: Municipal waste and household waste

Practical examples of successful shredding with WEIMA shredders

Want to tackle your waste problem?

Request a customized shredding solution now.

WEIMA portfolio for shredding municipal solid waste

The right machine for every material

Example applications from municipal solid waste recycling

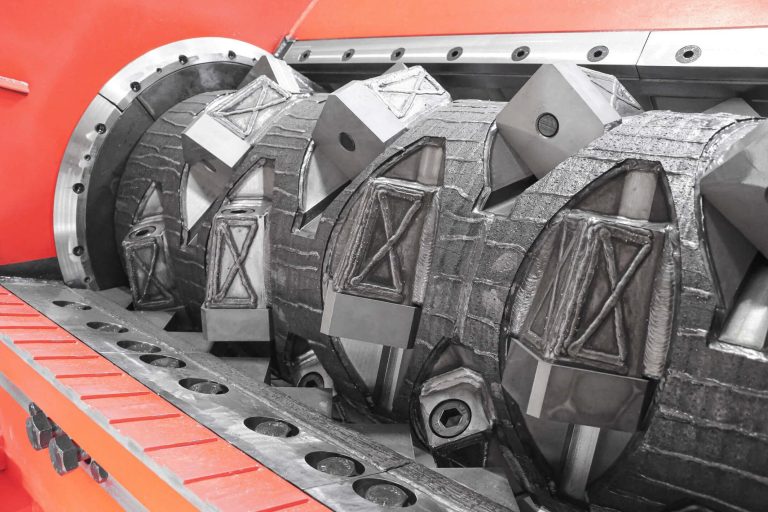

Heavy duty machine design against increased wear

WEIMA shredders for highly abrasive materials can be equipped with numerous options to protect against wear – for less downtime and lower maintenance costs. The solid machine frame ensures particular robustness. Rotors can be reinforced with Vautid and screens with Creusabro. Optionally, large knives (up to 130 x 130 mm) protect against foreign bodies, Vautid can also secure knife carriers.

To protect the rotor face plates, we recommend replaceable Creusabro wear plates that can be fitted on both sides. The cutting chamber can also be optionally reinforced with replaceable Creusabro plates. For particularly heavy-duty applications, we offer an approx. 20 mm thick, wear-resistant Creusabro screen.

Request the right shredder for municipal waste | household waste now

Quote request

Shredding of municipal waste & household waste

The most important facts at a glance

Good to know.

Member countries of the European Union recycled about half of their municipal waste in 2021.

See for yourself.

Have your material tested free of charge in our test center.

Practical examples and references: Household waste | Municipal waste Shredder

WEIMA delivers over 1,000 machines every year. Many of them are used for the recycling of household waste. You can find an excerpt of current reference projects here:

EkoPaliwa Chelm, Poland

Ultratech Cement, India

Wonder Cement, India

Solusi Bangun, Indonesia

Frequently Asked Questions about Municipal Solid Waste (MSW) shredding

Everything you need to know about safely and efficiently shredding Municipal Solid Waste (MSW) | Residual Waste.

Is a WEIMA shredder suitable for mixed municipal waste containing many different materials?

Yes. WEIMA builds shredders specifically designed for heterogeneous household and municipal waste streams that contain plastics, paper, textiles, wood, organics, and occasional metals. Twin-shaft pre-shredders such as the M8.28 are ideal for opening bulky items and handling irregular infeed, while single-shaft machines like the PreCut and PowerLine produce a stable output for sorting or RDF production. Optional wear protection packages and hydraulic drives help maintain performance even when stones or metal pieces are present. Additional metal separation units can be integrated to protect the cutting system and improve output quality.

How do I choose between a pre-shredder and a single-shaft shredder?

Your choice depends on incoming material condition and the desired output size. For bulky, compacted, or highly mixed MSW, a pre-shredder such as the M8.28 or PreCut 2000 provides the first size reduction and stabilizes material flow. For defined particle sizes — especially for RDF — a single-shaft machine like the PowerLine 2500 or 3000 is typically used in a secondary stage. If the waste stream is already uniform, a single-shaft shredder may be sufficient in one pass. WEIMA engineers can match cutting geometry, screen size, and drive configuration to your exact requirements.

Do we need a multi-stage shredding system, or can one machine handle everything?

Many MSW facilities use a two-stage system for optimal results, but a single machine may be sufficient for simpler goals. A common configuration uses a pre-shredder (M8.28 or PreCut 2000) to open bags and break down bulky items, followed by a PowerLine unit as a secondary shredder to achieve the desired RDF or sorting fraction. If your goal is basic volume reduction or coarse output, one shredder may meet your needs. The right design depends on contamination, feed variability, and downstream equipment requirements.

What happens to the material after shredding if we want to produce RDF?

After the initial shredding, the material passes through screening and separation steps to refine it into a consistent fuel stream. Lines commonly separate fines and coarse fractions, remove metals using magnetic systems, and apply air or optical sorting to eliminate inert materials. The coarse fraction — typically containing films, paper, rigid plastics, and wood — is preferred for RDF because of its higher calorific value. Typical values range from 10–15 MJ/kg, depending on composition. These steps help ensure stable performance in RDF combustion and co-processing systems.

How do these shredders help improve RDF quality?

They create a consistent, predictable particle size, which is essential for fuel preparation. When material is pre-shredded and then sized with a single-shaft shredder, downstream systems can remove fines, metals, and inerts more effectively. Uniform particle size improves mixing, drying, dosing, and combustion stability in RDF plants. The PowerLine 2500 and 3000 are commonly used as secondary shredders to refine output for fuel production.

Can these machines handle stones and metal pieces in the waste?

Yes — WEIMA shredders are designed for the harsh conditions of mixed MSW, but pre- and post-shred metal separation is still strongly recommended. Municipal waste often contains stones, screws, bolts, and other contaminants that can increase wear. WEIMA uses heavy-duty rotors, hydraulic drives, and optional Vautid or Creusabro wear liners to manage abrasive loads. Adding magnets, eddy current separators, and protective screens around the shredder helps remove unwanted items and extend machine life.

What output size can we expect from a PowerLine shredder?

The final particle size depends on the screen, the rotor type, and the moisture level of the material. PowerLine single-shaft shredders use interchangeable screens that allow operators to target the exact output needed. In RDF applications, these machines often serve as secondary shredders to produce a refined, uniform fuel fraction. A WEIMA specialist can recommend the ideal configuration after testing your specific MSW sample. Fine-tuning screen size ensures your output meets downstream specifications.

How much maintenance should we plan for?

Expect regular wear checks, knife inspections, and scheduled service to maintain high uptime. Daily tasks often include cleaning the cutting chamber and visually inspecting knives and counter-knives. Routine service involves rotating or replacing knives, adjusting the cutting gap, checking hydraulic filters, and monitoring wear liners. These liners protect high-impact zones and can be replaced during planned maintenance stops. WEIMA machines are designed for straightforward access to minimize downtime during service.

What are the benefits of using a hydraulic drive on a shredder?

A hydraulic drive provides high torque, smooth starts, and excellent load management. It can start, stop, and reverse under heavy load, which is valuable when processing mixed MSW where density and contaminants vary constantly. The system absorbs shocks from heavy or unexpected materials, helping protect the rotor and knives. WEIMA uses Hägglunds Bosch Rexroth hydraulic systems on models like the PreCut and PowerLine to ensure consistent, reliable operation.

What should we plan for in terms of space and layout?

Allocate space for safe feeding, discharge conveyors, service access, and dust control. These machines are large — some models have working widths of up to three meters — so consider layout for infeed and discharge belts, magnets, screens, and ventilation. Leave clear maintenance zones for knife changes and hydraulic access. WEIMA can integrate shredders into existing MSW lines or design complete upstream and downstream components to match your facility.

What are you looking for?

Explore all WEIMA solutions