High-torque drive

For demanding industrial shredding applications

Enormous forces are required for shredding, e.g., hard plastic parts. To ensure that the machines are constantly operational, the key components must be particularly robust. This is where Baumüller's high-torque drive excels: The high-torque motor is a high-pole electric direct drive. The drive system with high-torque motor achieves high torque even at low speeds.

Partners in performance

WEIMA x Baumüller

“The biggest advantage of the electric motor is its energy efficiency – and this convinced us.”

Interested in the High-Torque drive train?

We help you choosing the right drive train for you,

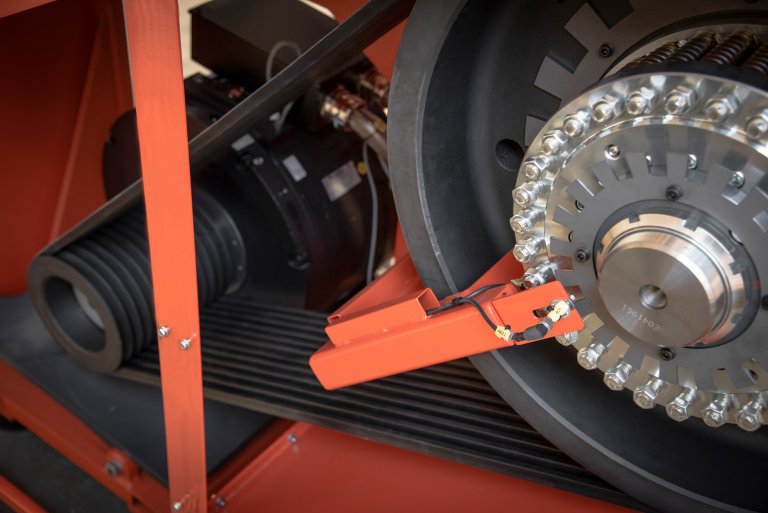

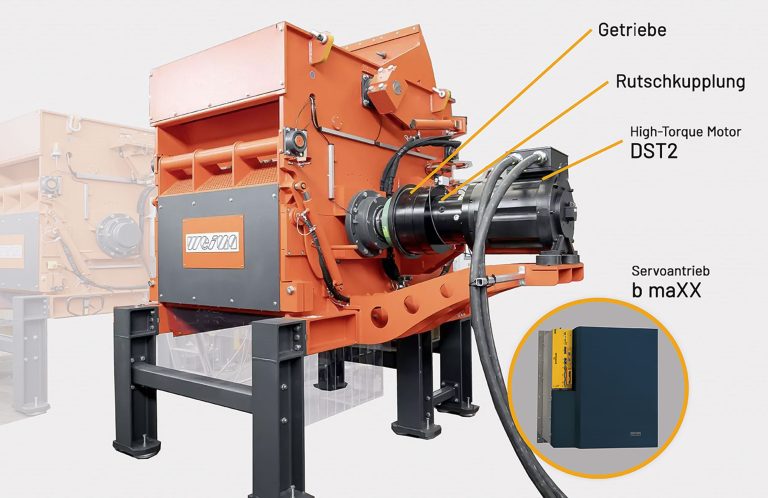

Robust technology for maximum service life

High-Torque drive train from Baumüller

The high-torque, multi-pole synchronous motor from Baumüller enables a high degree of insensitivity to foreign objects during the shredding process. The drive is resistant to shocks and vibrations and therefore has a particularly long service life – even when shredding challenging material flows. In addition, a slip clutch between the gearbox and motor protects the gearbox and rotor shaft from damage in the event of a blockage. Torque and speed can be precisely adjusted via a servo drive to achieve optimal results in terms of throughput and quality of the shredded material.

Low energy consumption thanks to direct drive

The use of direct drive technology reduces energy consumption by up to 30 percent. In addition, the drive is very easy to regulate and control. As the speed decreases, the torque increases – ideal for the shredding process. The low noise level is another advantage of the drive from Baumüller.

High-torque drive by Baumüller

Consistently high torque

Due to its motor characteristics, the high-torque motor enables high peak and rated torques across the entire speed range. The maximum torque from zero speed also allows restarting when the machine is full.

With servo drives and the use of encoder systems, the torque motors can also be controlled highly dynamically and react immediately to load changes. This results in high throughput and maximum machine availability, which benefits high productivity. The excellent speed stability also leads to a homogeneous shredding result.

Baumüller high-torque motors for high torques

The coordinated complete system consisting of motor, converter, gearbox, and slip clutch for shredders ensures perfect connection of the rotor shaft to the drive train and thus optimal power transmission. The new drive technology scores points with higher energy efficiency and significantly increases the reliability of the shredders. The innovative drive system thus not only enables more economical operation, but also more sustainable production. Thanks to direct power transmission and high torque, it delivers optimum performance, especially when processing demanding material flows.

Advantages at a glance

• High energy efficiency

• High efficiency

• Low maintenance

• Low noise emissions

• Insensitive to contaminants

• Compact and robust design

• High torque and breakaway torque

• Torque and speed precisely adjustable via servo drive

• Easy integration into existing concepts

Powerful yet energy-saving

An efficient drive is crucial for recycling machines. Optimal power transmission is achieved through a precise connection to the rotor shaft. Particularly economical: a fully electric high-torque drive system can significantly reduce energy consumption compared to conventional hydraulic and electric solutions.

What are you looking for?

Explore all WEIMA solutions