G.300 Hygienic Design

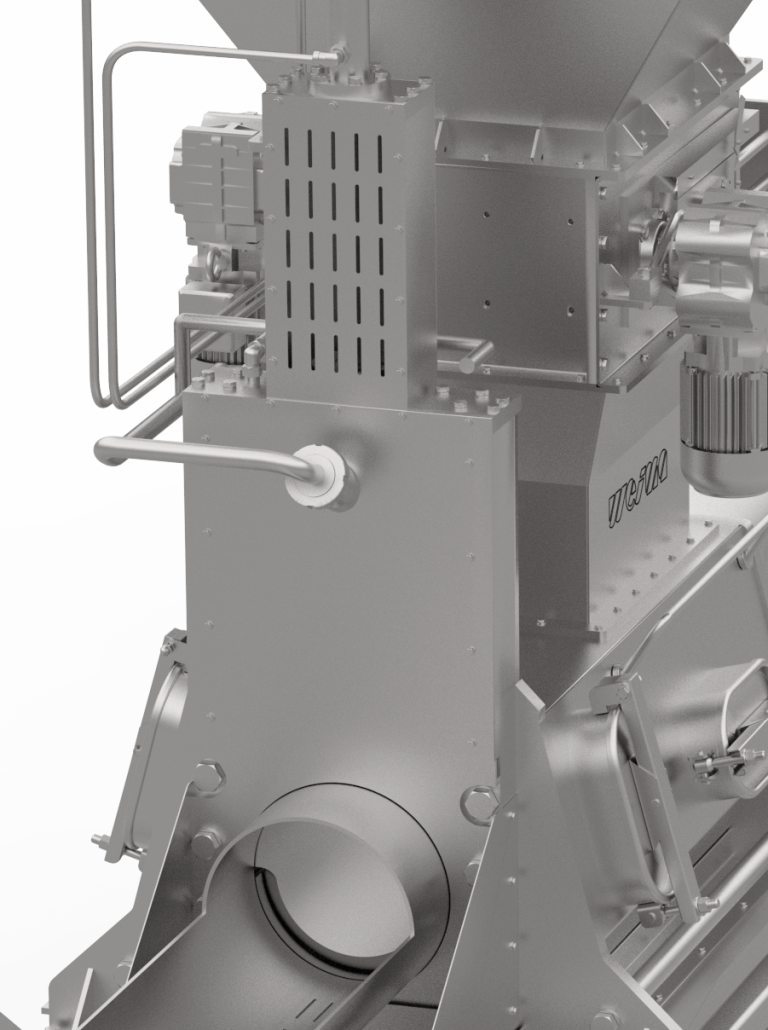

The use of machines in the production return process places high demands on quality, machine safety and hygiene standards. For this reason, we have developed optimized dewatering presses especially for reprocessing applications, which are (EG) Nr. 2023/2006 compliant and achieve the highest material throughputs with maximum reliability. With a production of 300 mm compacts, the WEIMA G.300 Hygienic Design achieves a throughput of up to 10 m³ of material per hour.

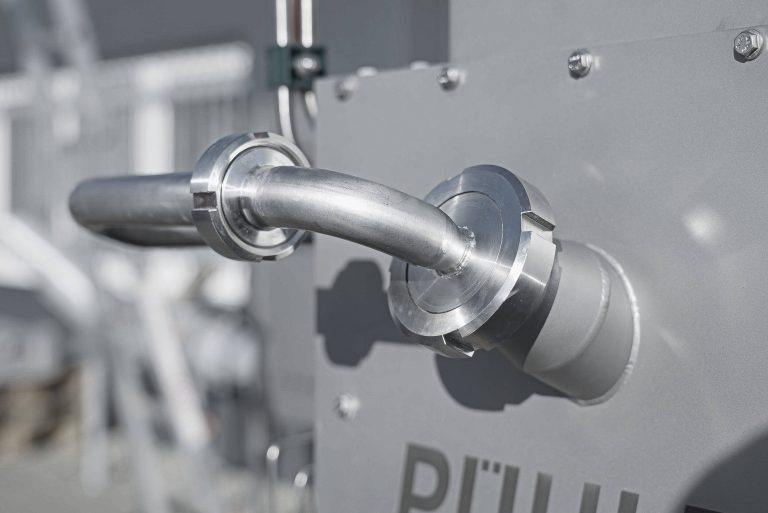

Hygienic Design presses achieve a higher ejection due to the curved discharge pipe. Depending on requirements, the discharge pipe can be extended. This means that it can be conveyed directly into a container or tipping skip without the use of a conveyor belt.

The high-quality Siemens PLC control system can be operated intuitively via the touch display. Parameters such as the pressing time, pressing force or the repress function can be adjusted quickly and flexibly. Upstream and downstream processes can also be conveniently controlled via networking in the PROFINET system. This gives you reliable and efficient control of your entire preparation process at all times.

To produce highly compacted, almost dry discs, the material is pressed between the press stamp and a pusher plate. This can be moved up and down hydraulically. As soon as the disc is produced, the pusher plate moves upwards and releases the discharge pipe. As a result, a particularly high degree of compaction is achieved at maximum throughput. The solid mechanical design is extremely easy to maintain and resistant to impurities and wear.

The hopper, into which the material to be dewatered is fed either manually, via a conveyor belt or using a lifting and tipping device, offers a particularly large buffer volume with a capacity of 1,000 liters. This provides sufficient reserve capacity to ensure a continuous process even if the material supply fluctuates. We also offer a hopper with a volume of 2,000 l for the G.300 Duo Hygienic Design.

In order to produce particularly clean discs, the discharge pipe can be equipped with a post-cleaning device. This rinses off the last product residues from the discs. The cooling water from the oil cooling system can be used for this process.

Highest throughput thanks to double return speed

If required, the Hygienic Design presses can be equipped with a double-pump hydraulic system. This enables an increase in throughput thanks to the double return speed of the press stamp.

During recompression, product residue can escape from the packaging and come into contact with packaging ink. To prevent these residues from contaminating the product, a second collecting tray is installed under the discharge pipe. From there, the pressed-out material is discharged to the side and can then be disposed of.

The integrated cleaning system cleans the dewatering press fully automatically. The Hygienic Design press is cleaned with up to 20,000 l/h through nozzles inside the machine. The integrated software controls the process.

If required, the hopper can be equipped with a horizontal agitator. This prevents material bridges from forming in the hopper – ensuring a constant supply of material to the pressing process.

Hygienically flawless thanks to hygienic design

Safe and clean. Thanks to their cleaning-friendly design, WEIMA dewatering presses maintain food safety, meet hygiene standards and simplify cleaning processes. This minimizes idle times.

The sensors on the collection tray provide information on the fill level and regulate the pumping out of the pressed material. If the collection tray or the containers connected to it are full, not only does the press switch off automatically, but the upstream processes (conveyor belt or lifting and tipping device) are also stopped. Depending on the material requirements, a screw or radial pump removes the dewatered liquid directly from the collection tray. This can then be used for the treatment process.

The screen that separates the product mass from the packaging is configured to suit your application. The size of the outlet holes can be between four and twelve mm. Choosing the smallest possible sieve size ensures that no fines from the packaging get into your product.

The pre-cleaning system with special cleaning-in-place (CIP) piping offers reliable cleaning without having to dismantle the system or components. The press is cleaned using spray balls attached to the areas in contact with the product. The Hygienic Design press can be optimally maintained and cleaned via five maintenance hatches.

Machines in the Hygienc Design series are made of stainless steel to ensure a long service life. This protects the machine body and control cabinet from heavy wear and corrosion.

WEIMA’s Hygienic Design presses empty and compress filled disposable packaging in a single operation. This allows you to efficiently drain, separate and compress beverage cans and containers, TetraPaks, yoghurt pots, cream spray cans, soft packaging and PET bottles and packaging. The pressed product can then be returned to the production chain in a treatment process and reused profitably.