Refine results

-

TH 600 M

![]()

Briquette press

Explore Machine -

TH 800 M

![]()

Briquette press

Explore Machine -

TH 1500

![]()

Briquette press

Explore Machine

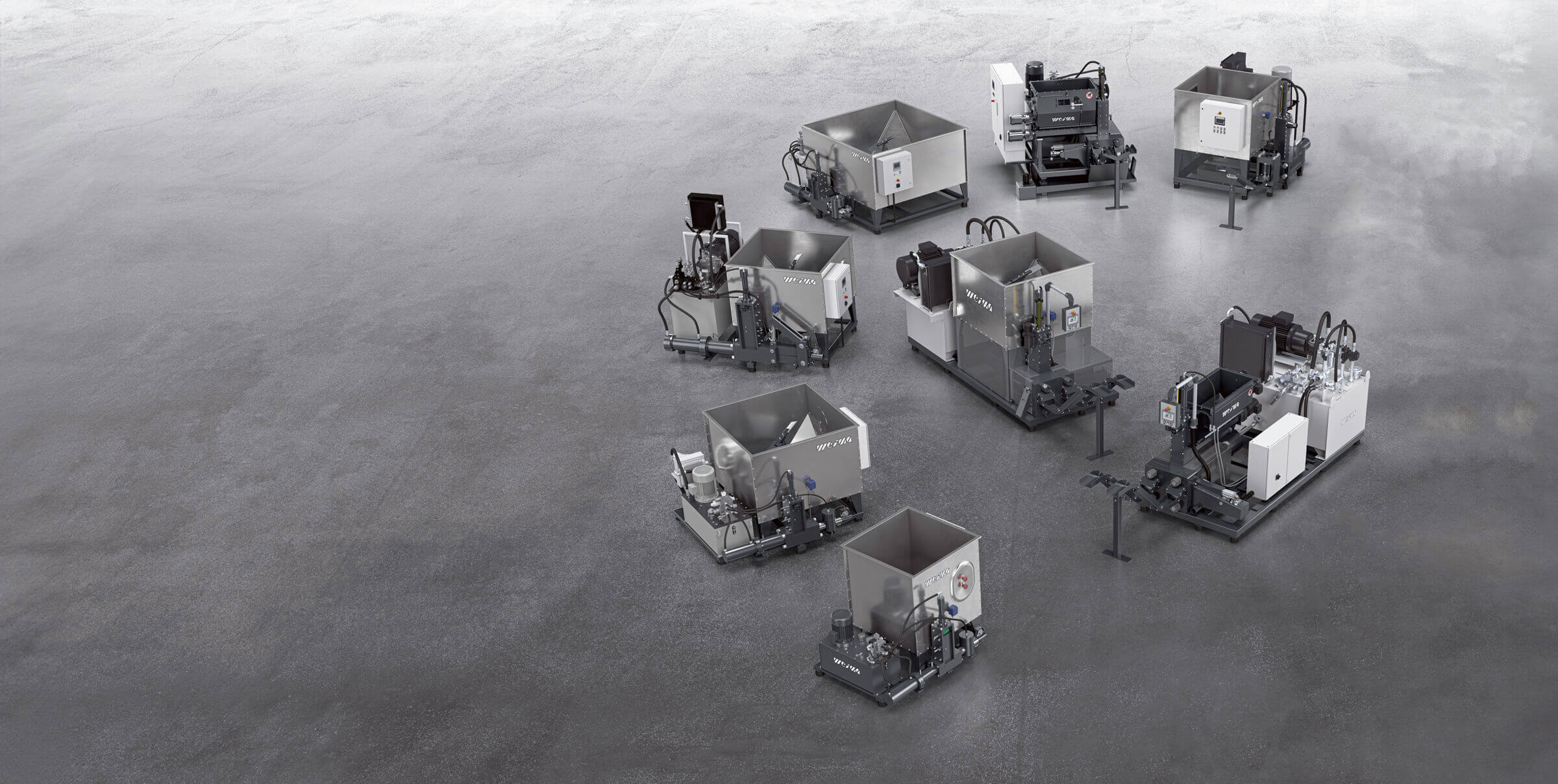

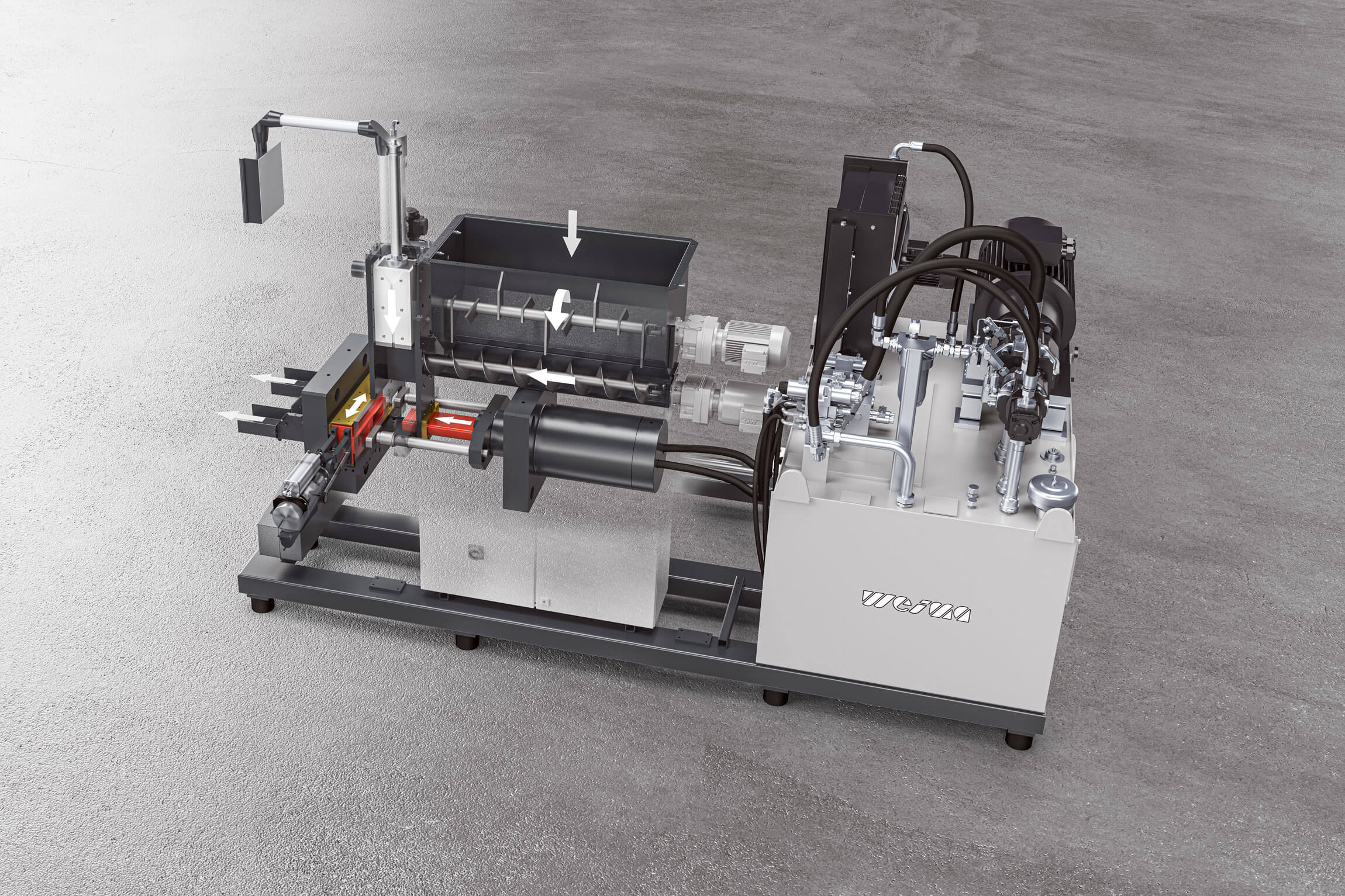

Series

TH Industrial

Industrial multi-shift machines for highest briquette quality and throughput demands

-

TH 814 / 820 S

![]()

Briquette press

Explore Machine -

TH 914 / 920 S

![]()

Briquette press

Explore Machine -

TH 1200

![]()

Briquette press

Explore Machine

Series

TH Standard S

Flexibly configurable press machines for medium to high throughput demands

-

C 140

![WEIMA C 150 briquette press]()

Briquette press

Explore Machine -

C 150

![WEIMA C 150 briquette press]()

Briquetting press

Explore Machine -

C 160

![WEIMA C 150 briquette press]()

Briquette press

Explore Machine -

C 170

![WEIMA C 150 briquette press]()

Briquette press

Explore Machine

Series

C

Compact entry-level machines for small to medium throughputs

-

TH 514 / 520

![]()

Briquette press

Explore Machine -

TH 614 / 620

![]()

Briquette press

Explore Machine -

TH 714 / 720

![]()

Briquette press

Explore Machine -

TH 814 / 820

![]()

Briquette press

Explore Machine

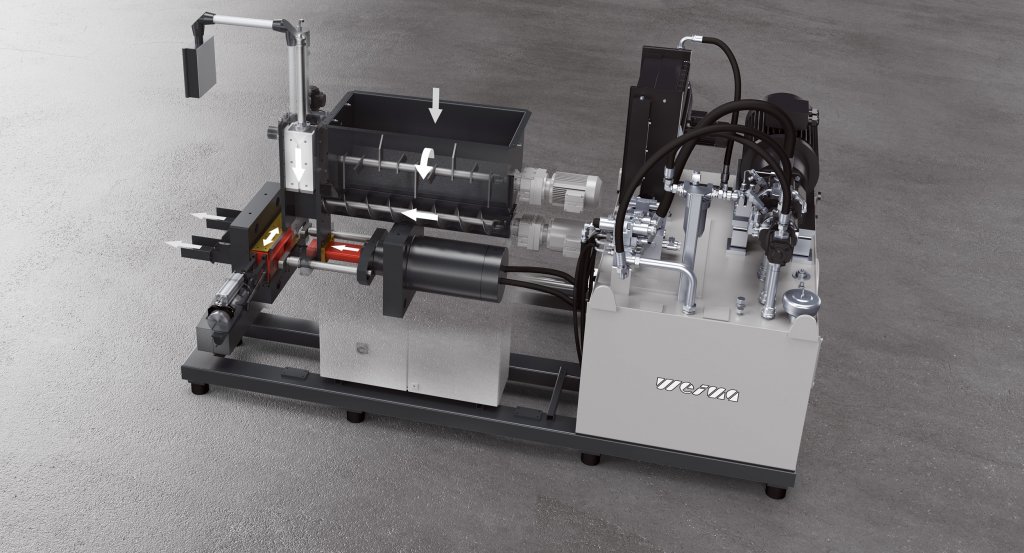

Series

TH Standard

Robust all-rounders with proven clamp technology for medium throughputs