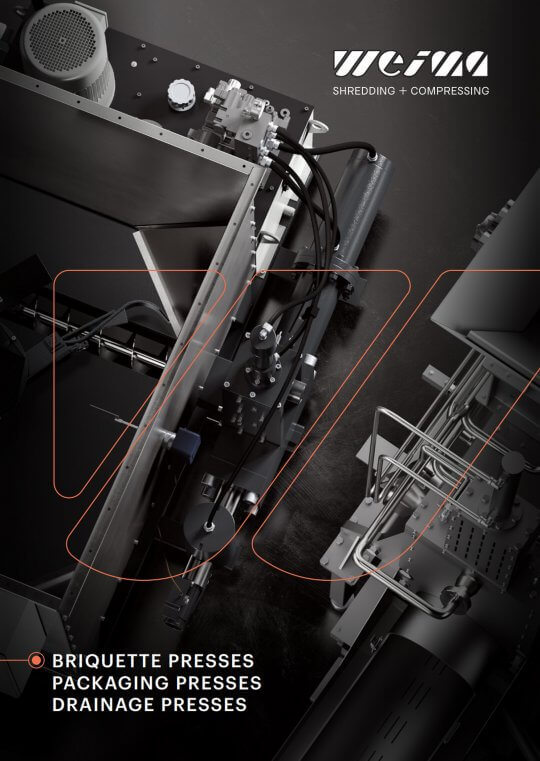

TH 800 M

The WEIMA TH 800 M briquette press was designed specifically with metal applications in mind. This machine allows for the briquetting of all types of metal shavings, chips, and turnings. Briquetting these materials into dense briquettes adds significantly to their resale value. Not only that, but this machine makes it possible to recollect valuable cutting fluids and emulsions for reuse. A tray and pump is located below the machine to make the collection of these liquids possible. The briquettes that are created can be smelted immediately, resulting in less slag and a higher material recovery rate.

The powerful axial piston pump of the hydraulic unit delivers an output of up to 37 kW. This allows the buildup of particularly high press pressures of up to 3,900 kg/cm2 (TH 800 M), resulting in extreme compaction of the briquettes produced. The remaining hydraulic components are also reinforced. The result: a longer service life and decreased maintenance costs. However, for those who require significantly less power depending on the application, motors starting at 5.5 kW are also available.

Maximum flexibility. For quick parameter adjustments (e.g. briquette length, number of briquettes per minute, density, etc.) during material changes, the large touch panel with Siemens S7 PLC control can be operated ergonomically. It also visualizes various processes in the machine. To ensure that the electronics are optimally matched to the machine, we design, build, and wire our control cabinets completely ourselves. We only use high-quality brand components – for example from Siemens, Allen Bradley or Rittal.

The separate oil tank of the Bosch Rexroth hydraulic unit has a capacity of approx. 600 liters and is equipped with efficient oil cooling. Due to this large quantity, the quality of the hydraulic oil can be maintained at a very high level for a long time - this is ideal for use in multi-shift operations.

All WEIMA briquettes are characterized by their dimensionally stable form. By using matrix technology, even better compaction and volume reduction can be achieved compared to pressing clamps. Depending on the application, the briquettes are then so dense that they even sink in water. They therefore have a density >1 (e.g. for aluminum a density of approx. 2.3, for other metals considerably more). Therefore, briquettes of TH Industrial series are ideal for subsequent selling. Their rectangular shape also makes them easy to handle, as they can be stacked for transport.

Modern machine design with matrix technology for the highest throughput rates

The use of a closed matrix for compacting loose chips, dust, or shredded materials, combined with a powerful hydraulic unit, results in extremely high briquette densities. TH Industrial series machines are state-of-the-art and extremely robust in design. Depending on the specific material, the throughput capacity is up to 300 kg/hr.

Low wear, easy maintenance due to chrome-plated and hardened matrix as well as exchangeable press plates

The movable matrix in which the final briquette is formed is subject to increased wear. For this reason, it is made of hardened steel and is also chrome plated. The press plate next to it can be replaced in just a few steps after wear. This ensures a smooth process.

The TH 800 M press loose materials into dimensionally stable round briquettes with a diameter of 80 mm. The briquette length can be variably adjusted on all machines. No binders or adhesives are used for compaction, only hydraulic pressing pressure.