WEIMA | KIRON

Your service center for WEIMA size reduction equipment in beautiful India

The joint-venture company WEIMA Kiron India Pvt Ltd. was founded in December 2019 by WEIMA Maschinenbau GmbH, Germany and KIRON Hydraulic Needs Pvt Ltd., India after a long-existing cooperation of more than 10 years. As a German engineering company, WEIMA is a proud manufacturer of single-shaft, multi-shaft shredders and briquette presses. KIRON is an Indian business group manufacturing equipment for specialized applications such as food processing & waste management and pumps for various industries and providing services for the same.

Local service for your WEIMA machines in India and Bangladesh

Time is money. Our goal is to provide fast and efficient customer service for your shredding equipment – to keep down times on a low. The Indian headquarters in Ahmedabad, Gujarat store thousands of spare parts. WEIMA Kiron's skilled Indian maintenance engineers are well-experienced and fully trained to serve your individual needs. In addition to spare parts, maintenance and operational contracts, we also offer pre-processing systems, including sorting and separation equipment.

With over 40 years of experience in size reduction and compacting equipment, WEIMA offers turnkey waste disposal and recycling solutions for various industries in India and Bangladesh.

- RDF and AFR for cement and power plant

- Hazardous waste recycling & household battery recycling

- Pulper rejects in paper mills

- Paper and corrugated cardboard industry

- Textile industry

- Cigarette industry

- Leather industry

- Food industry

- Metal industry

- Medical waste

- Biomass

You name it. We shred it.

Over 40,000 sold machines make WEIMA the world leader for shredding and briquetting technology. Our size reduction equipment is known for its robustness and durability – engineering Made in Germany. One of the things we have learned in the past decades is that waste streams come in different forms and materials. But there is one thing they all have in common: WEIMA can shred them!

Important information

Availability of local service makes installations, startup and training still possible – even during COVID-19 pandemic.

Instant availability: Spare parts stock for WEIMA shredders in Ahmedabad

The most common spare and wear parts are available ex stock India and can be supplied within short notice. We are carrying various rotor knives, counter knives, knife bolts, screens, hydraulic components, electric motors and more.

Need technical support or spare parts for your WEIMA shredder?

Call us: +91 8652207771 or write an email: info@weimakiron.in

Call us: +91 8652207771 or write an email: info@weimakiron.in

Skilled Indian maintenance engineers

Our local machine experts are available quickly and can be used for startups, installations, troubleshooting or repairs, training and preventive maintenance. Relocating of existing equipment can also be supported. The experienced engineers are actively working with WEIMA shredders for more than 10 years and are trained consistently in India or Germany.

Fully covered: Maintenance and operational contracts

For a fixed price we are offering our customers full maintenance contracts including wear parts. Optionally, operational contracts for WEIMA shredders are possible. WEIMA KIRON will have its own team at the shredder permanently to maintain and operate the equipment. Spare part flat rates can be included in such contracts as well.

Apart from this we offer the rental of the whole equipment accompanied by a frame O&M contract with specified duration (equipment as a service).

We offer additional equipment for pre-processing and loop back systems: feeding bunker, drum screen, FE-metal separation, picking station

Our goal is to keep the shredder's operational costs on a low level and the capacity on a high level. Alternatively, we are able to offer tailormade pre-processing systems or loop systems.

Heavy duty industrial shredders for different waste streams

Learn more about WEIMA single-shaft and multi-shaft shredders

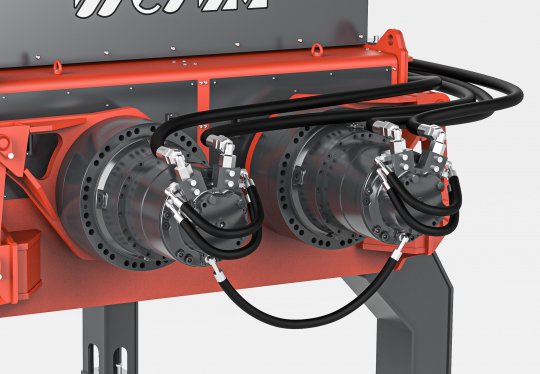

M8.28 two-shaft shredder: Heavy-duty pre-shredder with hydraulic drive

The WEIMA M8.28 shredder with twin-shaft technology is characterized by high throughput rates and shreds a wide variety of material streams for further processing, for example sorting or separation.

It allows convenient maintenance and optimal access to the cutting table thanks to an inspection flap. The cutting shafts can be configured with eight to twelve cutting disks, depending on the required throughput and particle size.

PreCut series: For extreme throughput requirements

The PreCut 2000-3000 series is characterized by extremely high throughput rates. PreCut machines are often used as pre-shredders in multi-stage processing plants, but are also suitable as stand-alone solutions. Thanks to Vautid wear protection, the solid PreCut rotor is particularly resistant to foreign matter. Reinforced side walls make the frame of the shredder extremely solid.

WEIMA PreCut single-shaft shredder

Did you know? A WEIMA PreCut series shredder is capable of

processing over 40 tons of waste material per hour.

processing over 40 tons of waste material per hour.

PowerLine series: Sharp cuts

The machines of the PowerLine series are universally applicable. Variable equipment and sizes allow an exact adaptation to your special requirements. The counter knives are user-friendly adjustable from the outside and protected by an additional cover plate.

WEIMA PowerLine components

W5 series: Maintenance-friendly all-rounders with swing ram

With working widths of 1,400 mm, 1,800 mm or 2,200 mm, the W5 series accommodates a wide variety of materials. The inspection flap and the lift-up screen make the single-shaft shredder particularly easy to maintain. Thanks to the wide conveyor belt cut-out, large quantities of shredded material can be removed quickly and cleanly.

Contact us

WEIMA Kiron India Pvt Ltd.

Shed. No. 22, Ashwamegh Industrial Park,

Navasari Lat, Village

Paldi Kankaj, Taluka Daskroi, Pirana

382425 Ahmedabad, Gujarat