At this year’s K trade show in Düsseldorf, WEIMA will be exhibiting two new plastic shredders with single-shaft technology: the revised W5.18 universal machine and the WLK 1000 with innovative FineCut rotor for secondary shredding. In addition, there is another machine premiere in the field of compaction. With the new PUEHLER C.200 press, fine particles can be dewatered and compacted in a single step after the washing process.

Trade Shows

Ilsfeld, 02.08.2022

The global demand for recycling technology for plastic post-consumer and production waste continues to grow in these turbulent times. This primarily includes machines for one of the first process steps – shredding.

If you are looking for a particularly powerful, maintenance-friendly and versatile plastic shredder, you need to look no further than the W5.18 (a further development of the successful WKS series) with an output of up to 280 kW. With its 1,800 mm long and 500 mm diameter rotor, the all-rounder for plastics of all kinds effortlessly shreds both hard plastics and tear-resistant fibers and films. The proven swing ram for aggressive, controlled material feed also helps here. The generously dimensioned inspection flap provides direct access to the rotor during service work.

WEIMA W5.18 single-shaft shredder

For particularly demanding applications, i.e., for heavily contaminated material (e.g., sand, soil or metallic residues), WEIMA offers special options for wear and corrosion protection. These include a Vautid shell or hard facing using weld seams for the rotors, additional wear plates in the cutting chamber or wear-resistant screens made of Creusabro or Hardox. Cutting blades are available in 60 mm and 80 mm edge lengths. All of this significantly extends the service life of the components.

Vautid weld-on for shredder rotor

Machines in the W5 series can be equipped with three different drive concepts. The hydraulic drive as well as the high-torque drive are particularly powerful, energy-efficient and robust against foreign objects. The electromechanical drive with the in-house developed WEIMA WAP gearbox will win customers over with its low investment and maintenance costs. Of course, all W5 machines have the connectivity features commonly found on the market for networked production.

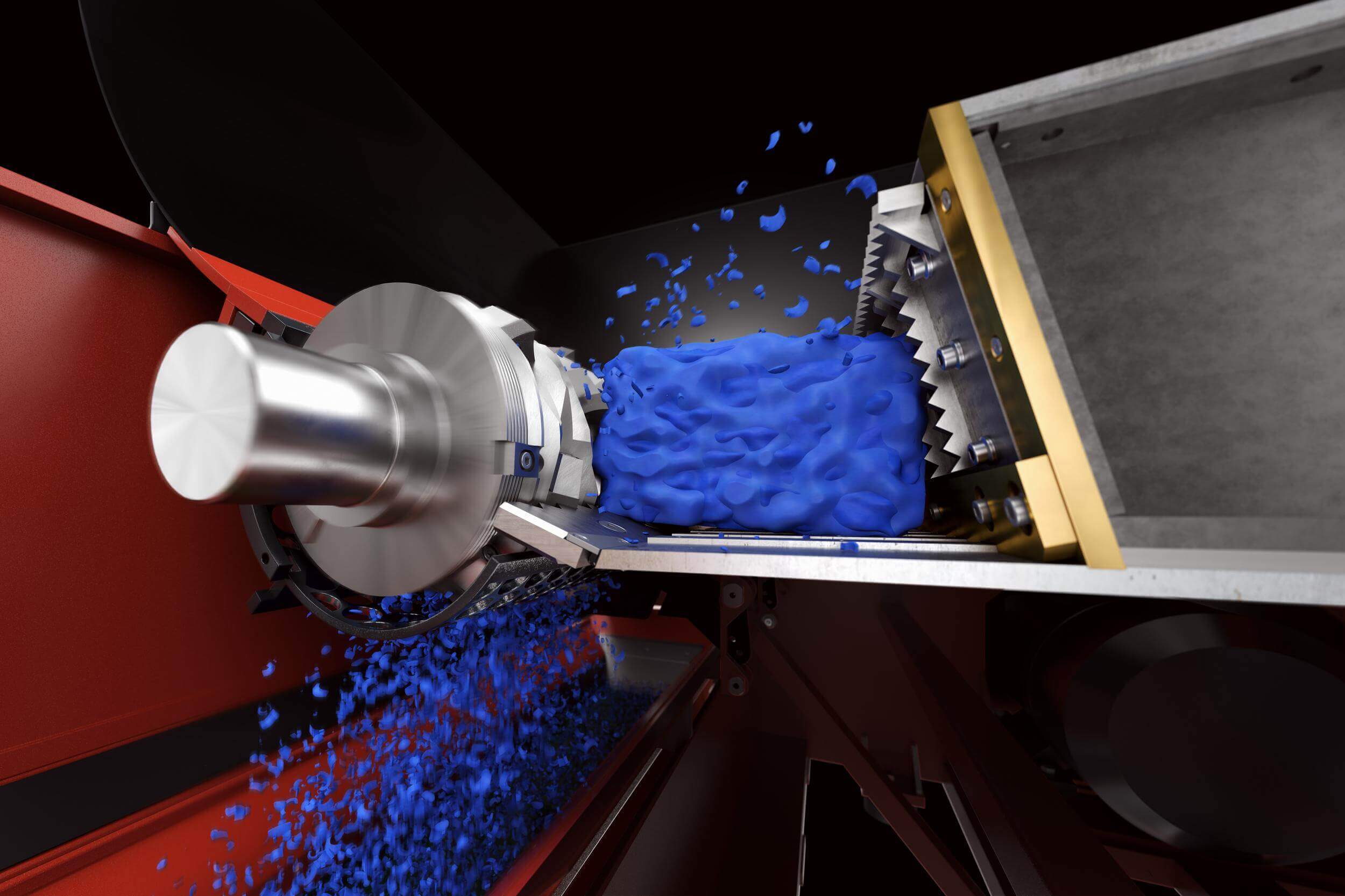

WEIMA produces over 1,000 solutions annually for shredding and compacting all types of residuals. The WLK 1000 shredder on display at the K trade show offers numerous advantages: a compact footprint, a screen basket that can be hydraulically lowered, various cutting geometries and equipment options and easy integration into production lines. The exhibited machine has an electromechanical drive with power belt and gearbox. The highlight is located in the cutting chamber. A 1,000 mm long FineCut rotor is installed there, which makes the shredder ideal for secondary shredding (up to 10 mm). The rotor works according to the shear cut principle, which combines in a robust form the properties of a classic shredder with those of a cutting mill.

WEIMA WLK 1000 single-shaft shredder

Many recyclers are familiar with the problem: the expensive disposal of fine fractions (fine rejects) after washing shredded post-consumer plastics. An important cost driver is wastewater that still adheres to the plastic. With the new PUEHLER C.200 drainage press, WEIMA is presenting an economical compact machine that provides a remedy with solid, low maintenance technology. A hydraulic pusher cylinder compacts loose, wet plastic flakes into handy, almost dry compressed discs with a diameter of 200 mm. The pressed-out liquid is discharged separately via a drip tray. PUEHLER presses can be operated both as a stand-alone solution as well as integrated in a production line. The lower weight of the compressed discs contributes significantly to reducing disposal costs.

WEIMA PUEHLER C.200 press for swarf, turnings and shavings

These and other plastic recycling solutions await you at WEIMA at the K trade show in Hall 9, Stand A39.

See WEIMA shredders in action:

In-house recycling of pool covers at Plastipak Limited in the UK:

To customer story

Shredding of production scrap at Plásticos Ojara in Colombia:

To customer story

Download this press release and pictures here:

To WEIMA media pool

Contact

Marketing

WEIMA Maschinenbau GmbH

Bustadt 6-10

74360 Ilsfeld (Germany)

Contact

Sign-up for our newsletter

Additional Information

We are WEIMA:

More than 40,000 machines sold worldwide! WEIMA has been manufacturing robust shredders, briquetting and drainage presses for the disposal and processing of all types of waste for more than four decades. Our machines include single-shaft shredders, four-shaft shredders, cutting mills, briquette presses, packaging and drainage presses. The popular blood orange machines are used in the wood, plastics, paper, metal and waste-to-energy industries.

Made in Germany. Built for the world.

Shredders, briquette and drainage presses from WEIMA are exclusively made in Germany and come from production plants in Saxony-Anhalt and Baden-Wuerttemberg. Every year, more than 300 employees work on around 1,200 customer solutions from around the globe. We have long-standing sales and service locations in the USA, Poland, India and China. More than 80 representatives supplement this global presence.

Newsletter

Sign-up for our newsletter today.

Sign-up for our newsletter