At this year’s K trade show in Düsseldorf, WEIMA will be exhibiting two new plastic shredders with single-shaft technology: the revised W5.18 universal machine and the WLK 1000 with innovative FineCut rotor for secondary shredding. In addition, there is another machine premiere in the field of compaction. With the new PUEHLER C.200 press, fine particles can be dewatered and compacted in a single step after the washing process.

WEIMA at K 2022

WEIMA electromechanical drive with WAP gearbox

K 2022 trade fair WEIMA booth

View through W5.18 inspection flap on rotor

WEIMA WLK 1000 single-shaft shredder for plastic applications with F rotor for flexible materials

Precious Plastic corner on WEIMA booth

New WEIMA F rotor for WLK 1000 shredder

Hägglunds Bosch Rexroth hydraulic drive motor

WEIMA owner Martin Friz on the WEIMA K 2022 show booth

WEIMA Teamwork

Smiling faces

Busy days on the WEIMA booth

WEIMA W5.18 single-shaft shredder with swing ram

Plastic shredders of the W5 series are available in working widths of 1,400, 1,800 and 2,200 mm, driven by a hydraulic drive, high-torque or classic electromechanical drive. All have a 500 mm diameter rotor, which is available in two versions. The V rotor, for example, is suitable for large plastic lumps or hollow bodies. The F rotor, on the other hand, is used for flexible materials such as films or fibers. The wide inspection flap provides direct access to the cutting chamber for maintenance purposes. The compact swing ram optimizes the shredding process. For highly contaminated material streams, WEIMA offers numerous options for wear and corrosion protection for the W5 series.

WEIMA W5.18 single-shaft shredder

WEIMA WLK 1000 Single-shaft shredder

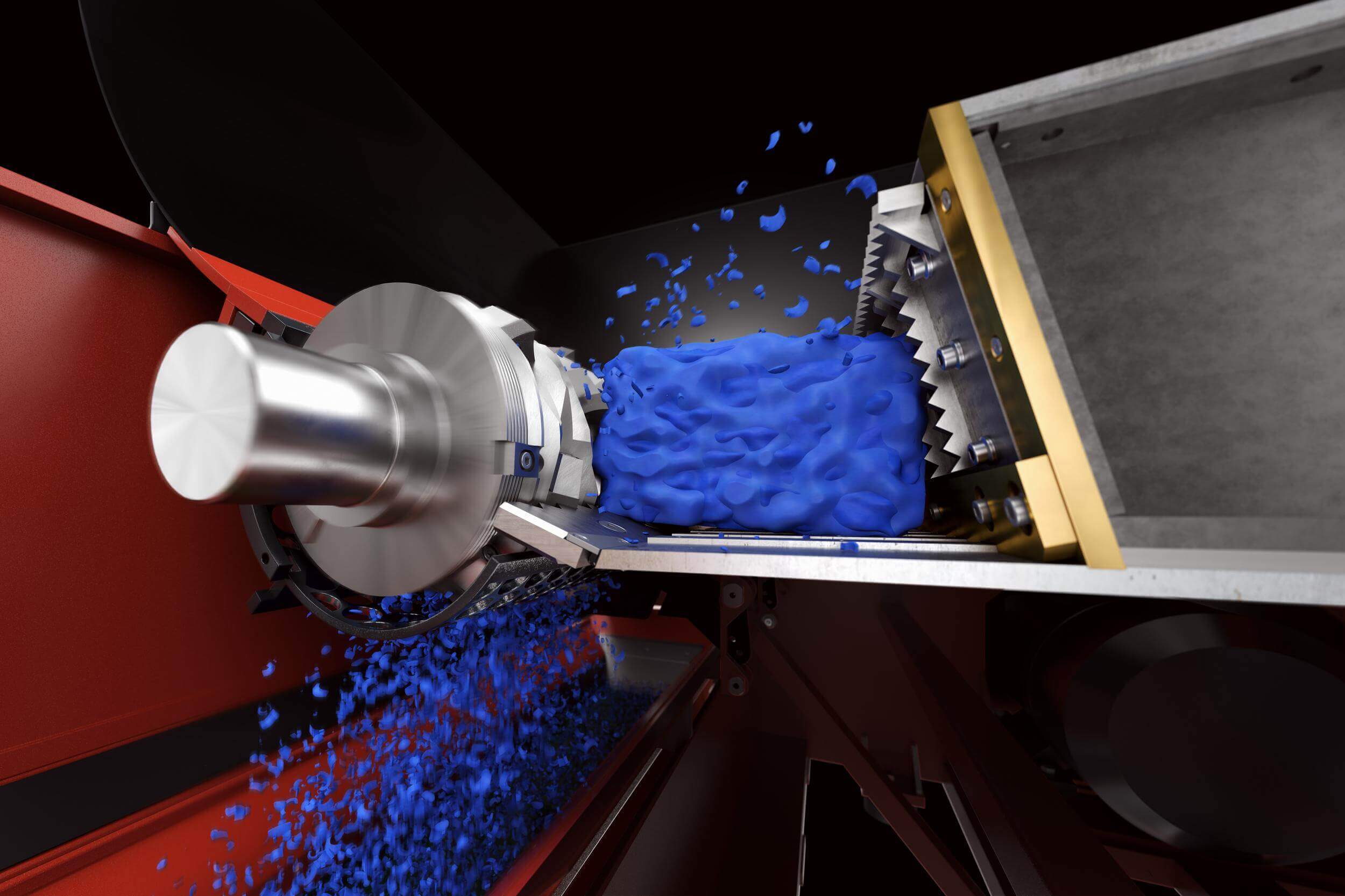

The advantages at a glance: compact footprint, hydraulically lowerable screen basket, many cutting geometries and equipment options, easy integration into production lines. The machine on display has an electromechanical drive with power belt including gearbox. The highlight is in the cutting chamber. A 1,000 mm FineCut rotor is installed there, making the shredder ideal for secondary shredding (up to 10 mm). The rotor operates according to the shear cut principle, combining the properties of a classic shredder with those of a granulator in a robust form.

WEIMA WLK 1000 single-shaft shredder

WEIMA PUEHLER C.200 chip press for plastic draining and compressing

With the new PUEHLER C.200 drainage press, WEIMA is presenting an economical compact machine that provides a remedy with solid, low maintenance technology. A hydraulic pusher cylinder compacts loose, wet plastic flakes into handy, almost dry compressed discs with a diameter of 200 mm. The pressed-out liquid is discharged separately via a drip tray. PUEHLER presses can be operated both as a stand-alone solution as well as integrated in a production line. The lower weight of the compressed discs contributes significantly to reducing disposal costs.

WEIMA PUEHLER C.200 press for swarf, turnings and shavings

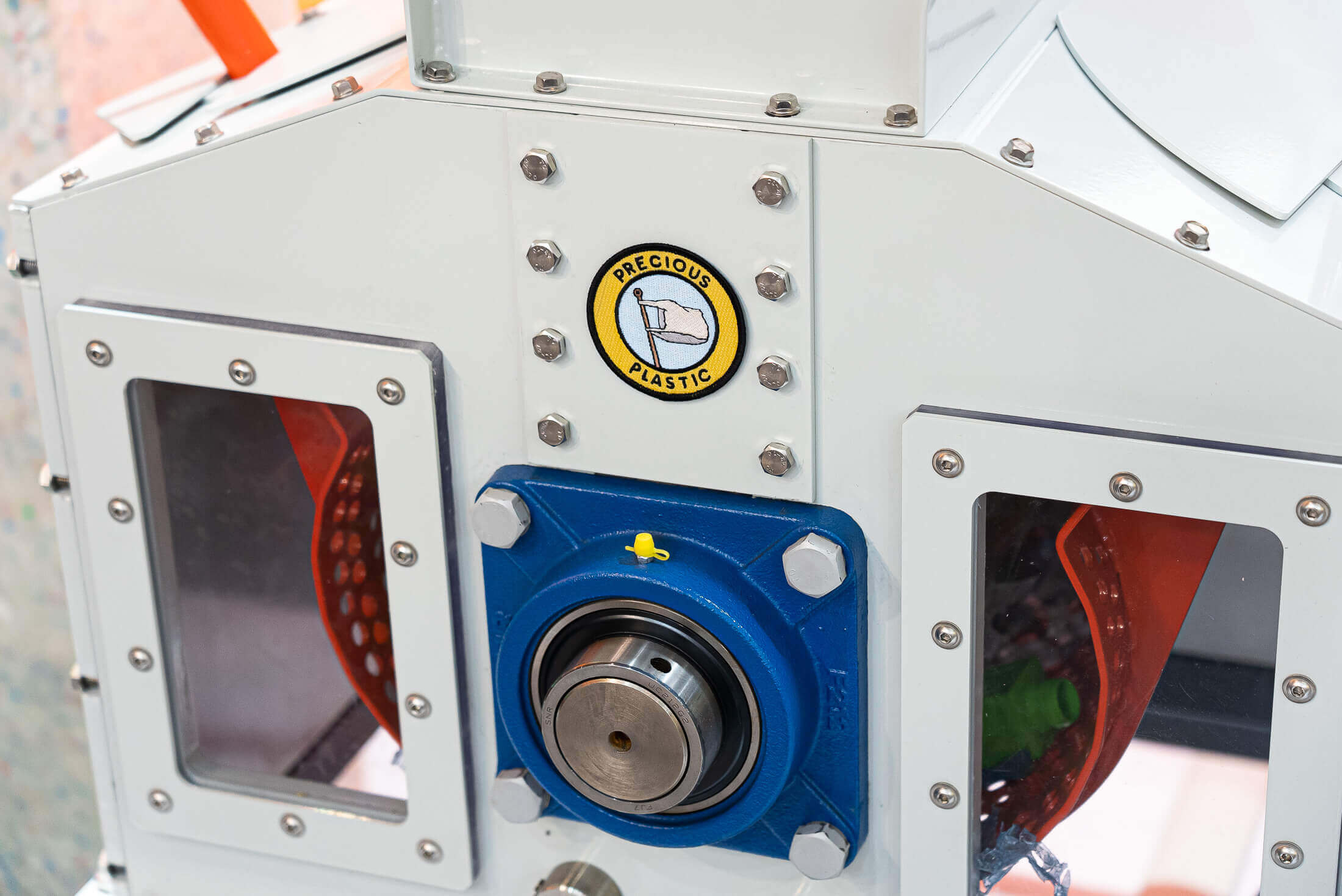

Precious Plastic x WEIMA

In cooperation with Precious Plastic, WEIMA has developed a new version of the "Shredder Pro" for the worldwide community in the recent months. The compact shredder primarily consists of standard parts and is designed to be easily reproducible. It is ideal as an entry-level machine for people who want to start their own small recycling business, but still want to achieve certain throughput targets. In addition, the shredder's low connection load of just 3 kW and particularly simple operation make it ideal for projects in developing countries and educational institutions. At the K trade fair, an injection molding machine from Precious Plastic will also be used to produce carabiners live on site from the shredded plastic flakes.

Precious Plastic logo

Plastic items made from recycled plastic waste

Production of recycled plastic carabiners

Precious Plastic brick wall made from recycled plastic waste

Yann Chauvin from Precious Plastic

Precious Plastic Shredder Pro closeup

Shredded post-consumer plastics

Interview with Yann Chauvin from Precious Plastic

Project insights of the Shredder Pro development and information about the K show in Dusseldorf, Germany.

Plastic recycling for everyone

The Precious Plastic project was launched in 2013 by Dave Hakkens in the Netherlands. The goal is to raise awareness about the global plastic waste problem and to provide open source technology to actively fight it. Over time, more than 400 workspaces have been created worldwide, involving more than 40,000 people to recycle plastic themselves.

More information about Precious Plastic can be found here:

Precious Plastic presentation on the WEIMA K 2022 show booth with Shredder Pro and injection moulding machine

Find us in

hall 9 | both A39.

We're looking forward to your visit.

K 2022 location plan