Hydraulic drive for WEIMA shredders

The efficient solution

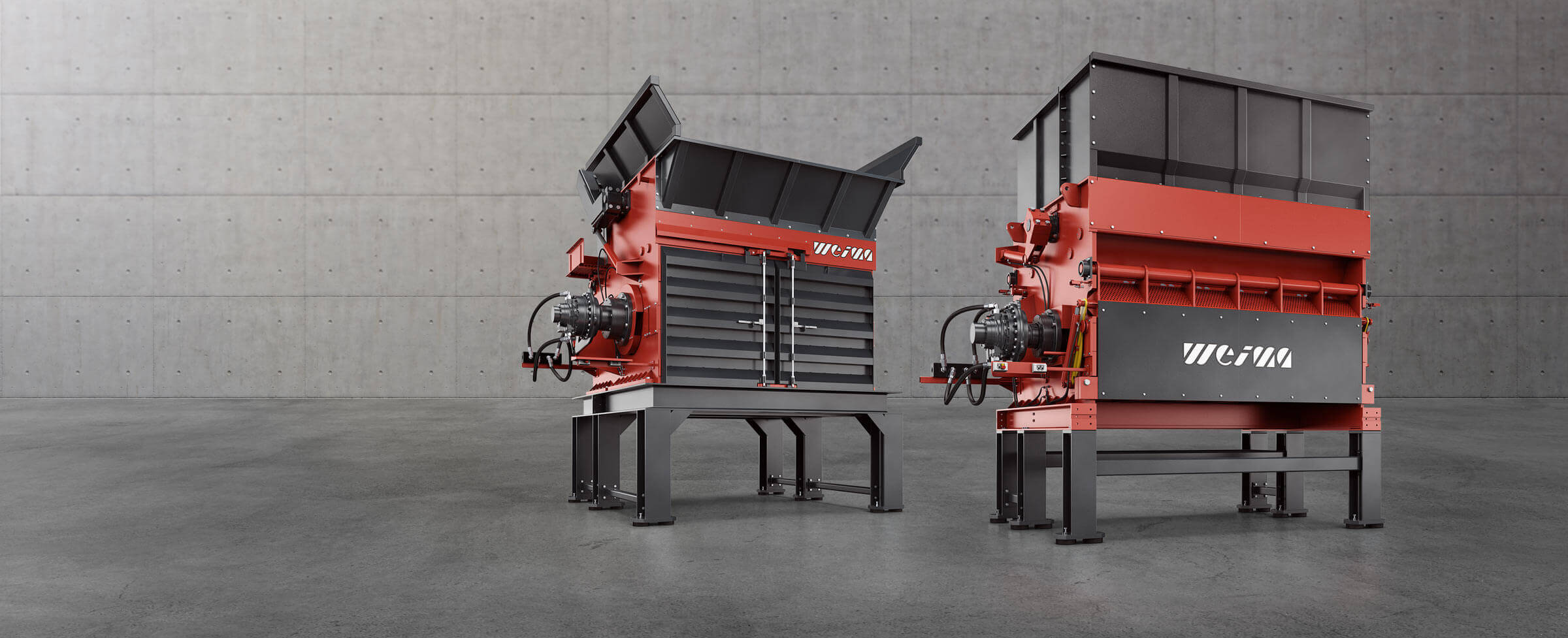

In addition to the conventional electromechanical drive and the high-torque drive, the hydraulic drive is a powerful direct drive option for WEIMA shredders that has proven itself with customers all over the world.

Partners in Performance: HÄGGLUNDS and WEIMA

The HÄGGLUNDS brand hydraulic drive used by WEIMA is manufactured by the company Bosch Rexroth. As a recycling specialist, WEIMA has been working with these hydraulic experts for many years.

Functionality of hydraulic drives

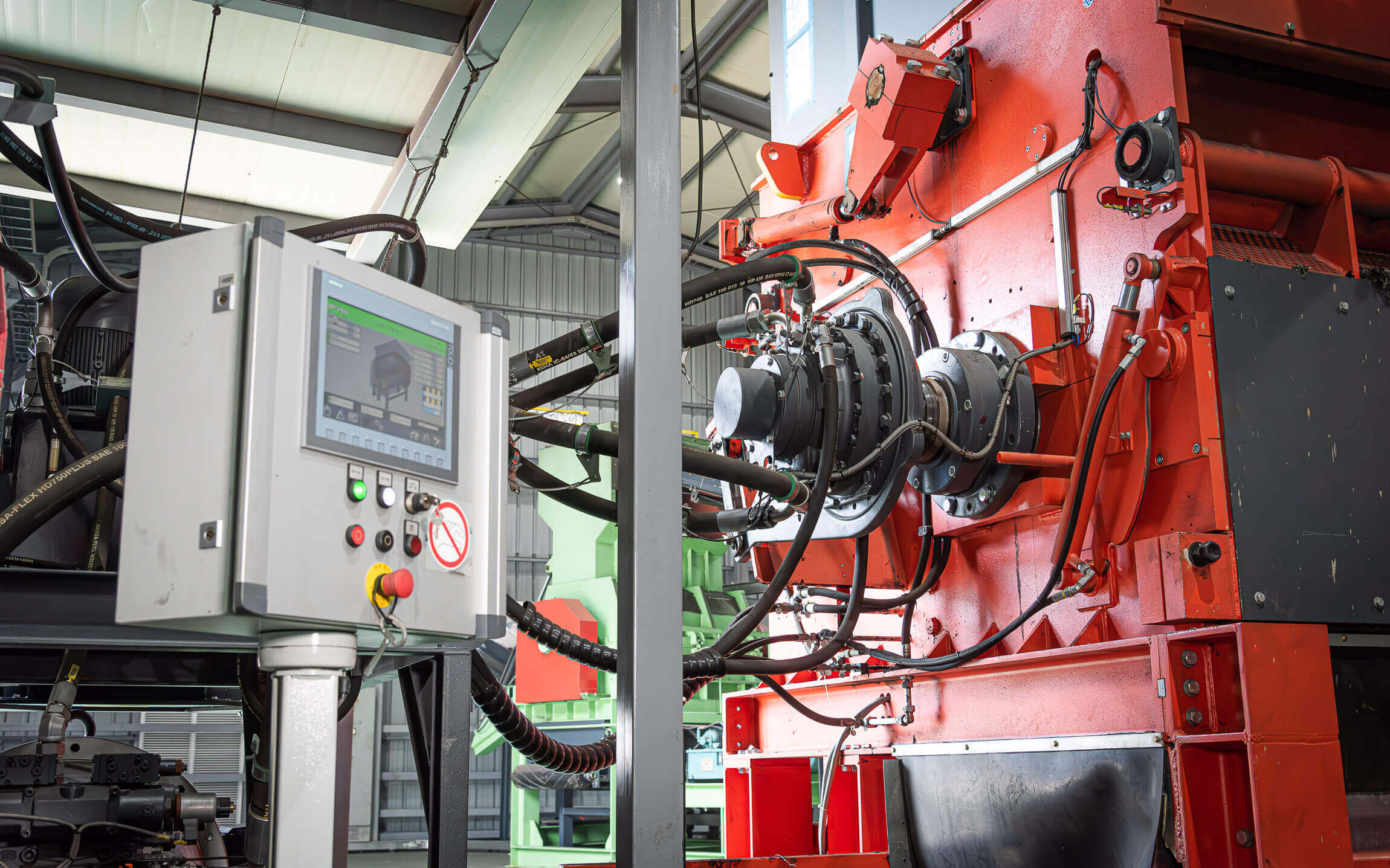

For users interested in a shredder with a hydraulic drive, this type of drive offers significant advantages. It enables smooth stopping, starting and reversing under the toughest working conditions, even at full load. In hydraulic systems, power is transmitted via hydraulic fluids such as mineral or synthetic oil. These fluids serve as a medium for the efficient transmission of power, energy, force and torque between the hydraulic pump as the prime mover and the hydraulic motor as the driven machine.

Why does WEIMA choose hydraulic drives from HÄGGLUNDS?

WEIMA CSO Kay Schulte has a conversation with Wolfgang Ehmke from HÄGGLUNDS Bosch Rexroth about the advantages of hydraulic drives für WEIMA shredders.

Advantages of hydraulic direct drives

Efficiency and frugality where it matters

The Hydro develops its full potential when accelerating the rotor and under high and fluctuating loads. Here it shreds with competitive efficiency and power thanks to the extremely low inertia in the drive and the favorable torque curve.

High power peaks are avoided from the outset by the drive concept and do not burden the electricity bill, nor does excessive connected load have to be provided.

As much torque as you need, for as long as you need it

The torque curve of hydraulic drives is ideal for shredding processes. Maximum torque is available for any length of time from speed zero.

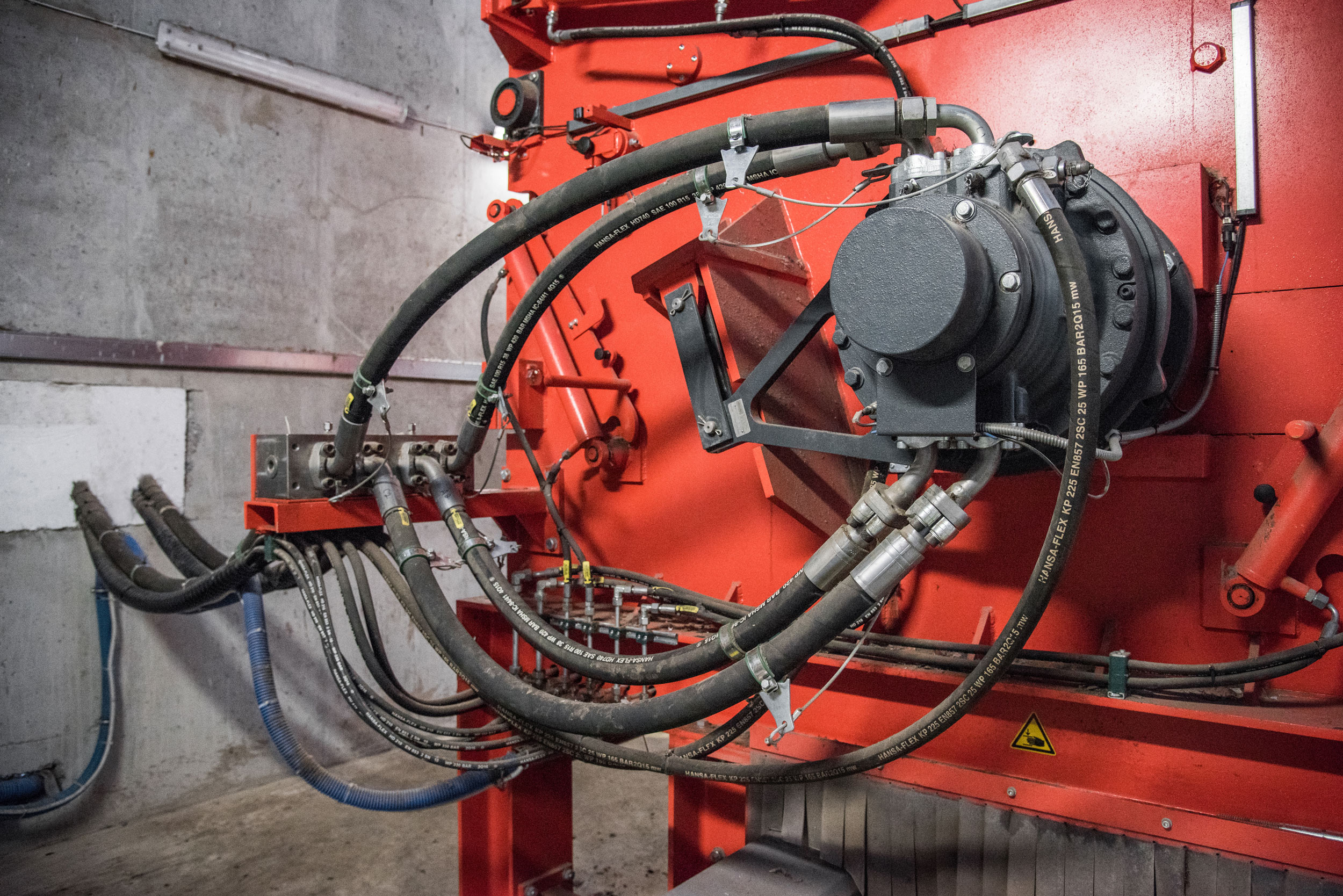

Due to the torque conversion when the electric motor and hydraulic drive are decoupled, the power transmission is direct and free of mechanical wear parts.

Unmatched robustness under extreme conditions

Hydraulic drive systems are completely unaffected by vibrations and other environmental influences and are therefore perfectly suited for use in harsh industrial environments. Traditional mechanical wear parts are a thing of the past here. Even with the hardest materials, the buffer properties of the hydraulic system protect your cutting unit.

The completely closed hydraulic circuit has no problems with dirt, moisture or temperature. Even in the depths of winter, the oil is gently brought up to temperature in the winter program and 100% availability is guaranteed.

Natural resilience against foreign objects

In the event of a blockage, the pump's pressure relief valve immediately limits the force. In combination with buffer properties, low inertia and the intelligent switch-off logic of our software, the result is a system that is inherently resilient to foreign materials. This effectively reduces or even completely prevents damage to the cutting unit, as we have been able to impressively demonstrate in realistic test series.

To the test videoProven simplicity

A Hydro combines proven, low-maintenance technology with high spare parts availability. From industry and agriculture to construction machinery, this technology can be found all over the world wherever reliability and robustness are required. Every shredder uses a hydraulic auxiliary unit, regardless of the drive concept. So why not expand the existing technology and use it for the main drive? The advantages are obvious: one technology for the entire machine instead of a wide range of complexity.

Hydraulic drives at WEIMA customers worldwide

In which applications is the hydraulic drive used?

In areas where heavily contaminated material such as domestic or commercial waste, agricultural film or mixed waste needs to be shredded, hydraulic drives offer clear advantages: Due to the absence of a conventional gearbox, which can wear out on impact, they are more resistant to foreign objects such as metal parts. A hydraulic drive also proves to be particularly efficient when an extremely high cutting force is required, for example when shredding PP, filaments, multifilaments or big bags, thanks to a high torque and breakaway torque. The hydraulic drive is also characterized by its flexibility. The infinitely variable regulation of the rotor speed allows the shredder to be optimally adapted to the material to be processed, regardless of whether it is hard or soft, solid or fibrous.