ReWork draining presses and system solutions

The production of food and beverages inevitably results in scrap material in the form of incorrect batches, incorrectly packed or labelled goods, offcuts and broken goods. All too often companies dispose of this valuable scrap, often as expensive hazardous waste.

With the machines of the G series, WEIMA offers automated system solutions for the dewatering and compressing of packaging and containers that do not meet the requirements of the manufacturer. WEIMA dewatering machines are uncomplicated and easy to maintain and can be integrated into any production line. With the recovered output, high-quality goods can be produced again.

Click here to learn more about rework:

ReWork draining presses and system solutions ReWork draining presses and system solutions ReWork draining presses and system solutions

Keeping scrap in the food cycle longer with ReWork presses

Learn more about the rework process, requirements and advantages of WEIMA presses

As a partner of the food and beverage industry, we are committed to providing sustainable solutions for reducing resource losses in food production.

Leverage recycling potentials with the use of WEIMA draining presses.

Definition: What is rework?

The rework process is an additional step in the production process of food, beverages and packaged goods. Priority is given to the avoidance of unnecessary waste and garbage resulting from not using production scrap.

By definition, rework is clean, unpolluted food (fresh goods) that is rejected from the production process. At the same time it is hygienically harmless and unadulterated. After successful processing, it can be returned to production as a high-quality raw material – for the same product or an alternative.

Rework process during the production of mayonnaise

ReWork process at dairy company Emmi, Switzerland

The avoidance of food waste is a top priority not only for social and ecological reasons, but also from an economic point of view, an alternative reuse within the food chain in the form of ReWork is more than desirable.

Requirements and regulations for rework

A rework process in food production must be clearly defined. This includes, for example, the proportion of rework that may be used in a recipe at a certain quantity. Legal requirements must be taken into account and complied with. It is important that rework materials can be clearly distinguished from non-recyclable waste products. This also applies to labelling and storage. Documentation and absolute traceability of the rework products is mandatory.

Dairy products are sometimes particularly suitable for rework applications. Emptied milk from mislabeled milk cartons can be reused for the production process of yogurt or cheese – without loss of quality.

Lehmkuhl (2019) Praxishandbuch Hygiene und HACCP

Clear identification of containers containing products for the rework process

Rework done right

The use of rework machines brings numerous advantages. The recycling of nonconforming but flawless products is traditionally a very time-consuming process, as packaging usually has to be removed manually.

With WEIMA presses the process can be completely automated. This includes automated loading, dewatering and even cleaning of the machine system. The control system of the draining press can also be seamlessly integrated into the production line. This makes companies both more economical and sustainable in their production, while broken goods and rejects can be recycled in an environmentally friendly and profitable way.

Milk cartons draining and compressing at Emmi

Application areas

The term rework is an established term in the handling of curd, sausage and cheese scraps, bread and sweets. The following industries also successfully rely on the integration of ReWork processes:Dairy industry, e.g. milk, yogurt, cream, dairy drinks, organic products, Skyr, etc.

Brewery industry, e.g. for canned beer

Beverage industry, e.g. disposable PET for spirits, juices, soft drinks, water or smoothies

Food industry, e.g. plastic bottles for mayonnaise, ketchup, mustard, remoulade, packaging of spreads, etc.

Detergent industry, e.g. liquid detergents, liquid soaps, washing-up liquid and pastes

Inquire about a rework press today

Request a quote

Responsible handling of food

Not only private households, but also bulk consumers, manufacturers and retailers producemany millions of tons of surplus food, which is disposed of as waste, often without alternative. However, this is avoidable. The aim must be to use resources as long and efficiently as possible in the food chain and to recycle them. The use of rework must not only be environmentally friendly, but also time-saving and above all profitable for manufacturers.

Rework process in the production of ketchup

Dewatering and compressing of milk cartons for rework

Typical sources of error in the production process

In order to recover products, the packaging has to be opened or destroyed. With WEIMA drainers you ensure that neither packaging parts, labels nor lacquer get into the rework mass. The danger of foreign bodies is thus minimized.

Lehmkuhl (2019) Praxishandbuch Hygiene und HACCP

Hygienic Design

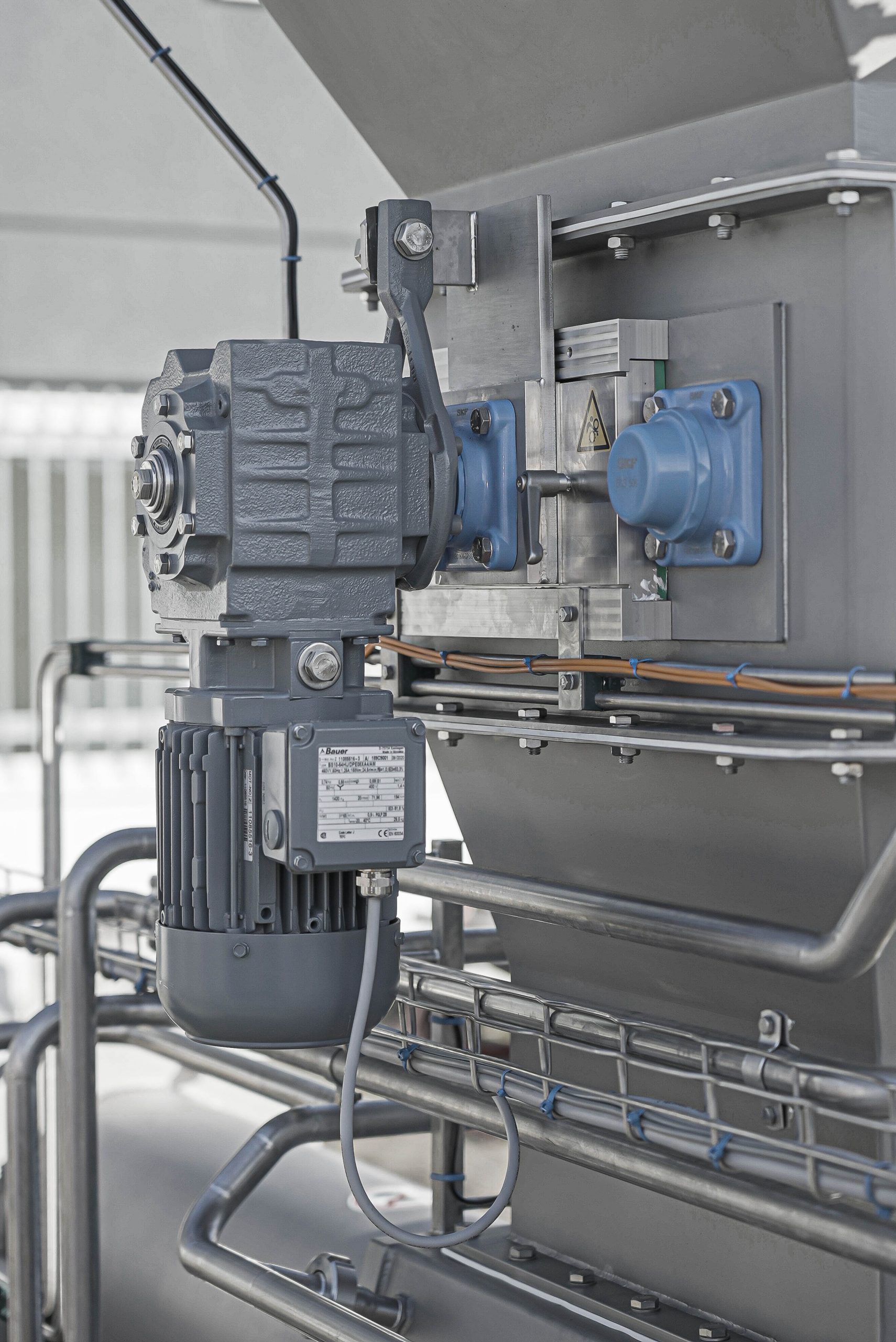

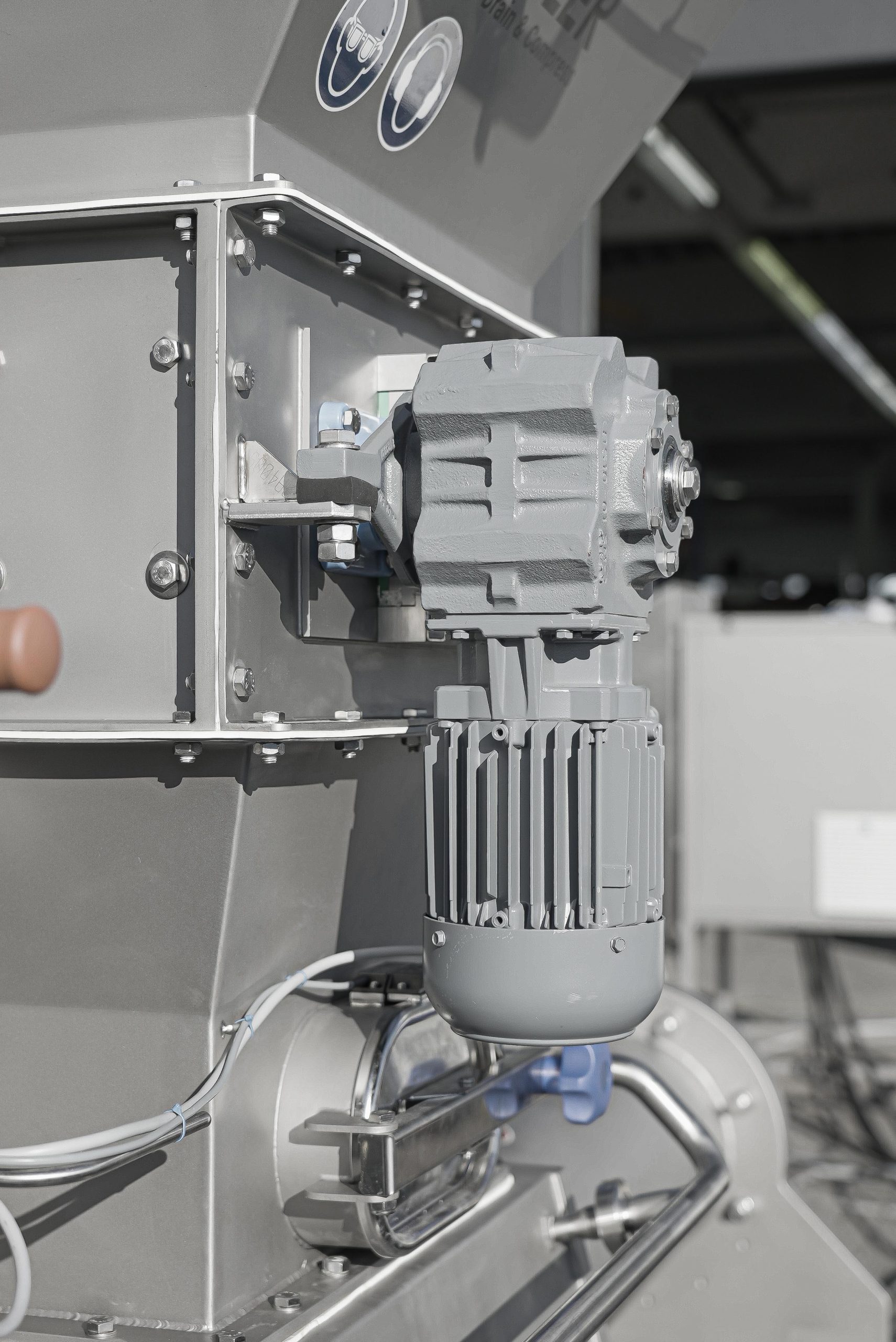

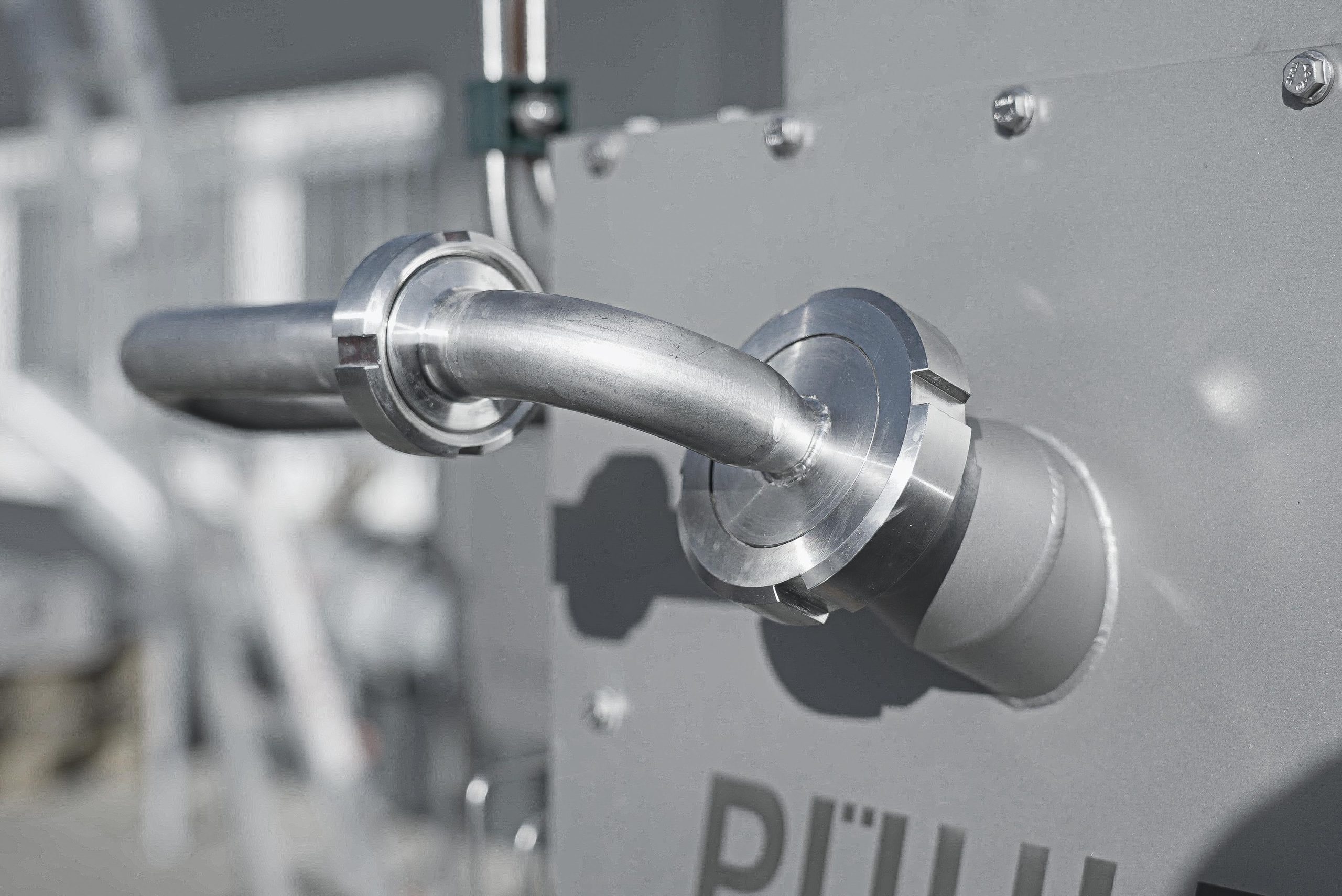

In hygiene-critical food production, the prevention of microbial contamination of the product is particularly important. Thanks to the cleanable design, WEIMA dewatering presses guarantee food safety, meet hygiene standards and simplify cleaning procedures. Idle times can thus be minimized.

The machine is designed as a round body so that there are no dead spaces where liquids stagnate and germination can occur. Double seals prevent contamination of the ReWork mass with lubricating oil, although WEIMA consistently uses only food-grade oils. The ReWork series is CIP-capable: At the push of a button, the system cleans itself via spray nozzles, and without the dismantling of individual parts. The integration of the drainer into your HACCP concept (Hazard Analysis Critical Control Point) ensures that you avoid dangers in the production process.

Rework applications from the industry

Compacted 500 ml beer cans

ReWork press

Drainer for rework

Emptying of plastic bottles

TetraPak® draining

Beverage cans during the pressing process

Compacted PET bottles

Smoothie bottles

Compacted PET bottles

Machine made of high quality stainless steel

Compressed plastic bottles

Drained milk packaging

"Misproduction is unavoidable during the startup and shutdown of filling lines and even more so during product type changeovers. However, the manual opening and emptying of the faulty packaging is no longer up to date for hygiene reasons alone, it also costs hard cash. Therefore, the investment in a WEIMA press often pays off within 12 months. "

Kay Schulte

Sales Director

Further process steps

Depending on the application and objective, further production steps are necessary before or after draining. This includes shredding or granulating, washing or briquetting the material. WEIMA also offers the appropriate machine technology for this from one source.

WEIMA rework system with press and shredder

Compacting. Shredding. Washing.

Step 1: Draining + compressing with G.300 ReWork

Step 2: Shredding with ZM 40 four-shaft shredder

Step 3: Washing with a Neue Herbold washing machine

See for yourself

We are happy to offer you the possibility to simulate your application in our facilities as realistically as possible. You have the possibility to send us your material or visit us directly in Abstatt.

Ask for an appointment now

Alternatively you can send us material for testing. Click here for the form.

Compresssed milk cartons discs

Special offer

Arrange a free material trial today.

Free material trial