Shredding and recycling IBC containers, plastic drums and canisters

Information on shredding, processing and disposing of intermediate bulk containers (IBCs), plastic canisters and blue plastic drums

Wherever liquid, semi-solids, pastes or solids have to be transported and stored, you will find them: IBC containers, plastic drums and canisters. Because, they are extremely flexible to use and are part of the standard equipment of any manufacturing industry dealing with logistics, transport and storage. Originally, IBCs were designed as disposable packaging, but it soon became clear that this packaging is perfectly suitable as reusable transport packaging, as well as for reprocessing. On this page, we show you how the proper disposal of discarded IBCs, but also production waste, works in terms of the circular economy.

Efficient IBC shredding and recycling at Dansk Emballage in Denmark

Our customer Dansk Emballage in Denmark uses a WEIMA W5.18 single-shaft shredder for shredding IBC containers.

What is an IBC container?

Intermediate bulk containers (short: IBC) are reusable transport packaging that can be used in many areas. The containers are an enormously stable construction that offers a high level of safety during transport and storage. They are easily transportable, storable and offer a practical alternative to drums and tank trucks. The tanks facilitate the transport handling of liquid as well as granular materials considerably.

The origin of the IBC

Various IBC manufacturers and companies claim credit for the invention of the versatile container. For one, a logistician for the paint manufacturer Herberts is said to have had the idea of designing a cube-shaped container adapted to a pallet as early as the 1960s. In 1975, entrepreneur Udo Schütz from Rhineland-Palatinate also developed a cubic container for transporting liquids and free-flowing materials. And an employee of the chemical company Dow Corning applied for a patent on "intermediate bulk containers" in the USA in 1992.

What are IBC containers made of?

The most common form of IBC is the rigid IBC, also called composite IBC or K-IBC. It consists of a cuboid, translucent plastic container, a galvanized steel grid and a pallet. The extrusion blow-molded plastic tank is made of high-density polyethylene (HDPE). The tubular frame surrounding it is made of steel. The pallet bolted underneath is made of steel, wood, plastic or a mixture of wood and plastic. In addition, IBCs are often equipped with discharge taps to drain residual materials at the bottom of the container.

What are IBC containers made of?

Furthermore, pallets can also easily be shredded with WEIMA shredders as well.

Pallet recycling

What IBC sizes are there?

IBCs are available in a wide variety of designs and dimensions to cover almost any application. In the standard version, an IBC container holds about 1,060 liters and has a base area of about one square meter, which corresponds to the size of a Euro pallet. In addition, there are also containers that hold between 500 and 3,000 liters.

What are the types of IBC containers?

- Composite IBC: plastic container + grid cage + pallet

- Plastic IBC: plastic container without tube frame

- Metal IBC: made entirely of stainless steel

- Flexible IBC: big bag made from PP (see big bag recycling)

- Foldable IBC: foldable container made of plastic

- Heatable IBC: metal IBC with heater

Plastic drums and canisters

HDPE drums and canisters are commonly used as disposable containers for bulk handling, transportation and storage of liquids, semi-solids and pastes. They are typically made of polyethylene (PE) or high-density polyethylene (HDPE) and are available with or without lids. Available in capacities ranging from 3.6 to 220 liters, plastic drums and canisters are also approved for the transport of hazardous materials.

IBC or drum?

The ideal transport solution

There are many reasons why IBCs have prevailed over cylindrical drums as a means of bulk packaging. Compared to round drums and other tanks, they offer maximum functionality. For one thing, the containers make much more efficient use of storage space; for example, only four drums can be stored or transported on a pallet, holding a total of 800 liters – an IBC of this size holds 1,000 liters. In addition, only one operation is needed to fill and empty the tanks, which makes work much easier. Thanks to the integrated pallet, IBCs can be transported by forklift truck or pallet truck and can be stacked optimally.

IBC or drum?

Recycling of intermediate bulk containers

What IBC recycling can look like in practice is shown by Recon Packaging from Manchester: The British company recycles defective IBC plastic bladders with a WEIMA WLK 15 single-shaft shredder. The shredded material is then used as raw material to manufacture new containers.

Where are IBC containers used?

- Petrochemical industry (oil, gas, solvents, cleaning agents, adhesives, acids, alkalis)

- Pharma and cosmetics industry (pharmaceuticals, tablets, solvents)

- Food industry (Liquid, granulated or powdered ingredients such as fruit concentrates, dairy products, syrups)

- Beverage industry (viticulture and fermentation, spirits production)

- Agriculture (sand, cereals, pesticides, insecticides)

- Automotive industry (Flammable paints, varnishes, AdBlue, gasoline)

The above list is a selection of applications for IBCs and does not describe a recommendation. In addition, there are many other industries in which the transport containers are used.

What are reconditioned IBCs?

A reconditioned IBC container (also Reko-IBC) is a container that has undergone a multi-stage cleaning process. The refurbishment of intermediate bulk containers that have already been used is known as reconditioning. The tank containers are pre-washed if they are heavily soiled and then cleaned inside and out so that all residual materials are removed. The condition of the containers is also checked. This also includes their leaktightness. This is the only way to guarantee that the IBCs are still ready for use. Sticker residues are removed and repairs are made to the pallet. Finally, the IBCs are returned to the cycle.

What are reconditioned IBCs?

Did you know?

More than 200 million IBCs are in circulation worldwide, with around 10 to 20 million more being added each year – and the trend is rising.

Source: Packwise

Practical examples and references: IBC shredding

Mauser, production waste

Janus Vaten, post-consumer and post-industrial recycling

Viridor, post-consumer and post-industrial recycling

Time-Technoplast, post-consumer and post-industrial recycling

How are IBCs disposed of and recycled properly?

The first step in waste processing or recycling is usually shredding - and this is also the case with IBCs. IBCs, plastic garbage cans and containers can be fed into the hopper of the WEIMA shredder without manual preparation, or also in bale form, by conveyor belt, crane or forklift. The plastic is pressed against the rotating rotor by the hydraulic ram and uniformly shredded to a homogeneous particle size. Depending on the application and customer requirements, WEIMA shredders reduce IBCs to a particle size of 60 - 80 mm. This is ideal for further processing. The discharge usually takes place by conveyor belt to the next process step.

If required, shredders for the recycling of oversized containers can be equipped with a secondary pressing device. This means that even large hollow bodies such as tanks can be reliably shredded.

What happens to the shredded drums and containers?

After shredding, the plastic flakes are washed and dried in a washing plant. These can then be recycled into regranulate in a recycling extruder. The pelletized plastic waste can then be reused in production, for example for pallets or corner protectors. This not only represents a major cost-saving potential, but is also sustainable entirely in the sense of the circular economy.

Inhouse-Recycling

The production of IBCs by extrusion blow molding also often results in production waste and rejects, for example in the form of squeeze-off edges, slugs or deformed containers. These can be shredded and ground directly on site. The plastic granules can then be fed directly back into production.

WEIMA also offers shredders for the recycling of plastics lumps and purge that arise during the production of plastic parts by injection molding.

Recycling plastic lumps

Moreover, besides reconditioning and recycling, there are many other ways to reuse used IBCs, for example as rainwater barrels, raised beds, pools or even chicken coops.

From hazardous goods container to raw material

Intermediate bulk containers are also approved for the transport of hazardous materials. However, transporting hazardous materials, such as caustic solutions, solvents or acids, always presents logisticians with a challenge: the proper disposal of the containers. When it comes to the environmentally compatible recycling of this contaminated waste, the aggressive properties of the material are extremely critical. For this purpose, WEIMA offers particularly robust shredding solutions, for example with wear-reinforced designs of individual machine components.

While clean plastic containers can be recycled without washing, it is particularly important for recycling facilities for contaminated IBCs that the crushed plastic flakes are cleaned before further use. This is done with the help of a washing plant. There, the flakes are washed and dried. Subsequently, a special degassing extruder ensures homogeneous granulate quality.

Did you know?

It is regulated by law that composite IBCs may be used for a maximum of five years for use with hazardous goods.

Source: Rekubik

It is also possible to recycle IBCs without prior separation of the plastic tank and mesh cage. WEIMA's robust shredders can easily shred both plastic and metals such as steel. The metal scraps are then separated from the plastic flakes using appropriate separation technology such as metal separators or metal detectors. Both material streams can then be recycled separately.

Closing the packaging loop with recyclates

Manufacturers of IBC containers have also recognized the trend towards sustainability: In the multilayer extrusion process, for example, an inner container can be made entirely of recycled HDPE, which is then surrounded by layers of virgin material. The stored product therefore only comes into contact with virgin material. This increases the recyclate content to up to 40% and can save more than 8 kg of CO2 per IBC. The result is a maximum recycled plastic ratio and a high level of food safety for the containers.

In need of an IBC shredder?

Request a quote

Heavy duty machine design

WEIMA shredders for processing highly abrasive materials can be protected with various options to reduce wear and thus downtime and maintenance costs. The heavy wall thickness of the machine frame makes WEIMA shredders particularly robust. The rotor can be reinforced with Vautid, the screen with Creusabro. To protect the cutting knives against the impact of foreign objects, large knives with edge lengths of up to 130 mm x 130 mm can be selected. If the number of knives is small. Vautid can also protect knife holders.

To avoid increased wear of the rotor face plates, we recommend the installation of replaceable Creusabro wear plates on both sides. The cutting chamber can also be reinforced and optionally lined with exchangeable Creusabro plates. Wear protection does not stop at the screen, which defines the material size. For particularly high wear, we offer a screen reinforced with Creusabro with a wall thickness of approx. 20 mm.

Vautid rotor coating for wear protection

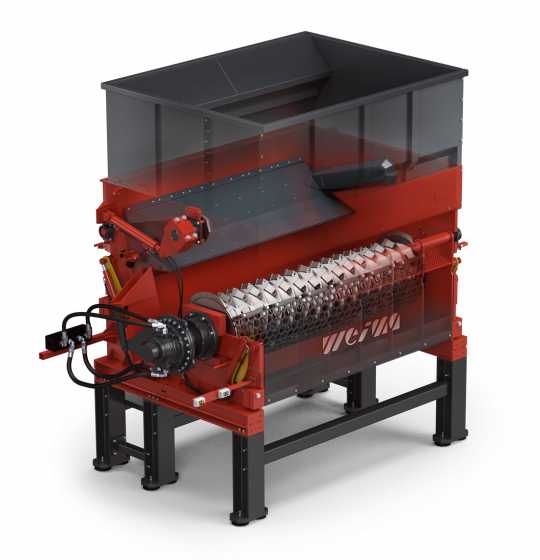

WLK series: highly productive plastic shredders

Machines of the WLK series are ideally equipped for a wide range of plastics tasks. The machine design is characterized in particular by durability and robustness. Thanks to the conveyor belt cutout, all machines can be seamlessly integrated into any production line. They also offer numerous options in terms of drive and cutting geometry diversity.

WLK 1500 shredder components overview

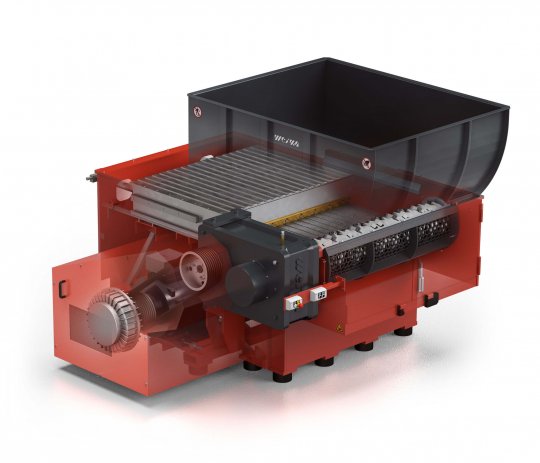

W5 series: Easy-to-maintain all-rounders with swing ram

With rotor lengths from 1,400 to 2,200 mm, the W5 series shredders shred large-volume plastic tanks and plastic tanks without any problems. The hydraulically upward-swiveling screen basket and the inspection flap enable quick removal of foreign bodies and facilitate maintenance. Large quantities of plastic flakes can be removed via the wide conveyor belt cutout.

WEIMA W5.18 shredder components overview

PowerLine series: Sharp cuts

The machines of the PowerLine series are universally applicable. Variable equipment and sizes allow exact adaptation to your special requirements. The counter blades are user-friendly adjustable from the outside and protected by an additional cover plate.

WEIMA PowerLine shredder

ZM: Four-shaft technology

Voluminous plastic parts, such as IBCs and canisters, are particularly suitable for shredding with four-shaft shredders of the ZM series. The plastic containers are shredded between the two cutting discs and pressed through the cutting gaps between the cutting discs with the two clearing discs. The screen placed underneath defines the particle size of the shredded material.

X-ray view of a WEIMA ZM 40

Hydraulic drive

Hydraulic drives from Hägglunds / Bosch Rexroth have no gearbox and are therefore particularly insensitive to many impurities. Speed and torque can be adjusted without current peaks. The robust drive provides high torque at low kW power. The speed can be variably adjusted by means of a regulating pump.

Hydraulic drive from Hägglunds Bosch Rexroth

Only at WEIMA

Heavy-duty machine design

for solid plastic lumps and rigid plastics

Adjustable counter knives

for continuously sharp cuts

Large feed hopper

for voluminous parts, without material build-up

Easy maintenance

for minimized downtimes

Many drive options

for maximum throughput

Fast service

for highest customer satisfaction

All from one source:

Machine, conveyor system, metal detection, support, spare and wear parts

WEIMA headquarters Ilsfeld (Germany)

See for yourself

The WEIMA show room is equipped with shredding and briquetting machines of all sizes and technologies. This enables us to simulate your application as realistically as possible. You have the possibility to send us your material or visit us directly in Ilsfeld. From our gallery you have the best view directly into the cutting chamber. So you can observe the shredding process live.

Request an appointment now

Alternatively you can send us material for testing.

Click here for the form.