The Pipelife Group is a leading manufacturer of plastic pipe systems in Europe. The company's flagship products are created at its Stathelle facility in Norway, where PE pipeline pipes hundreds of meters long and up to 2.50 meters in diameter are produced for use throughout the world.

PE-Recycling at its very best

PE-Pipe shredding and recycling

Pipelife, Norway

Sustainable PE plastic recycling with WEIMA S7.30 shredder and extruder

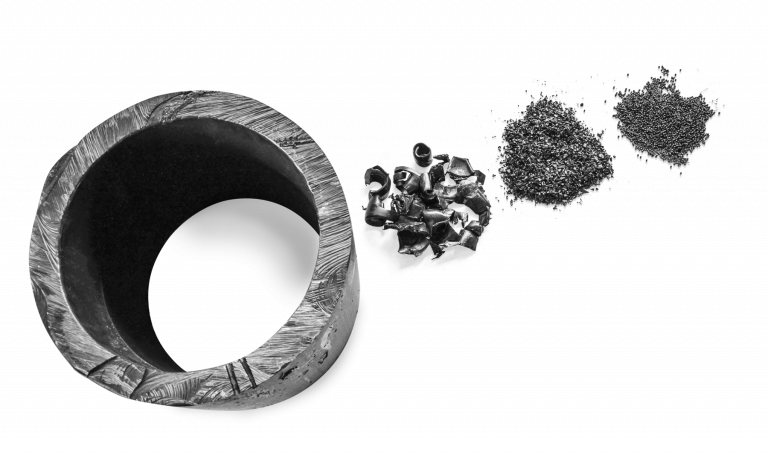

The way to achieve the objective was clear: First, shred pipe pieces that could no longer be recycled using the WEIMA S7.30 shredder. Then supply the shredded material via a screw conveyor to a granulator. The extruder used after this, which includes drying, ultimately converts old PE plastic residue into recycled regranulate, which in turn can be supplied into the raw material cycle. It is stored in giant silos on the company grounds. Nothing goes to waste in this sustainable solution.

Do you want to tackle your waste problem?

Request a customized shredding solution now.

Simple feeding and powerful shredding of large plastic pipes in the shredding process

The shredding process is both simple and ingenious. To keep the effort required as low as possible, the feed hopper was dimensioned so that even pipeline sections 2.50 meters in diameter could be loaded into the shredder in one piece with a forklift truck. The rest is taken care of by the innovative, high-throughput V rotor, fitted with 135 cutting blades, which reduces the pipe walls 10 cm thick to pieces no larger than 50 mm.

Maximum power and flexibility thanks to hydraulic drive

The steel colossus is driven by WEIMA’s powerful 160 kW hydraulic drive. Stopping, starting and reversing are possible at any time, even under the most difficult conditions and at full load. With its simple design and fast response time, the hydraulic drive is nearly insensitive to contaminants. Extremely high torques and the rotational speed can be adjusted flexibly, quickly, uniformly and steplessly, without creating current surges and without having to use a frequency inverter. Due to the low connected load with the same or higher throughput, less electrical power is required, which makes it possible to reduce operating costs overall.

Reconditioning PE waste has benefits beyond financial considerations. This technological advantage provides impressive confirmation of the company's vision of continuously improving "the quality of life through innovative and highly effective solutions to protect water and energy.“ As WEIMA sees it, everything fits together perfectly.

From PE pipe section to reusable granulate

A closed loop in terms of the circular economy.

Our team of experts will support you.

We will find the right recycling solution for your application.

Sign-up for our newsletter

Newsletter

Sign-up for our newsletter and get all the latest updates in your mailbox

Sign-up for our newsletter

What are you looking for?

Explore all WEIMA solutions