Woodwolf

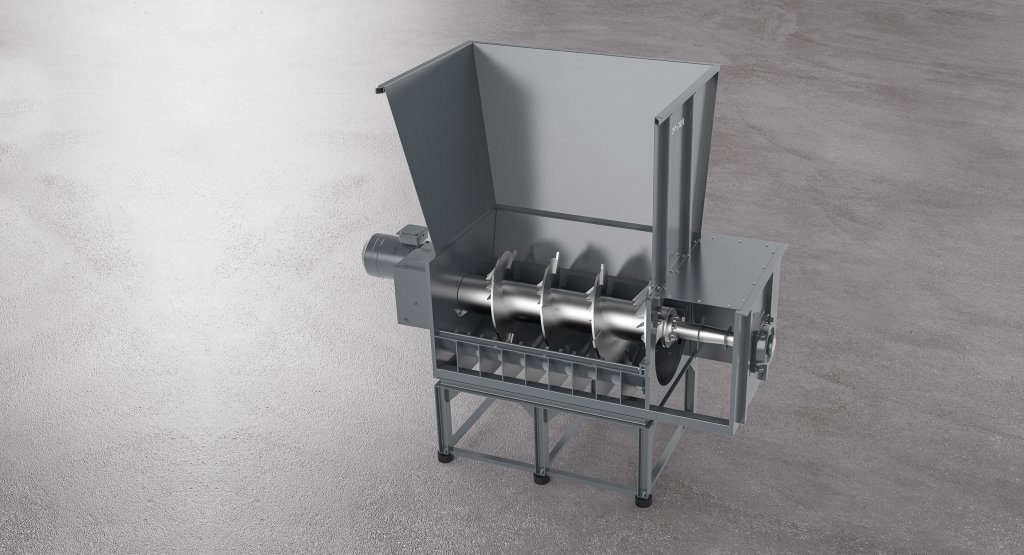

The Woodwolf machines of the crusher series belong to the classic pre-shredders. Unlike single-shaft shredders, they do not have a rotor and a counter-knife. Material is therefore not cut, but it is instead broken up. For this purpose, a screw with a diameter of 1,000 mm, which lies horizontally in the machine body, is used. It crushes and tears pallets, boxes, or furniture to approx. notebook paper-sized pieces. These can then be transported further to the secondary shredder via a conveyor belt.

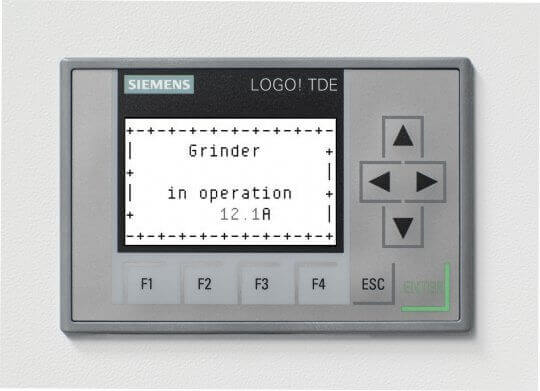

All control cabinets are designed, wired, and built by WEIMA in Ilsfeld. They are equipped with a high-quality Siemens PLC control system. The operation is done by a few easy-to-understand buttons. Keep it simple.

WEIMA Woodwolf and WL 10 single-shaft shredders

Compared to many other pallet shredders, WEIMA primary crushers make it possible to feed several pallets at once. The extremely robust hopper with reinforced loading edge provides a large buffer volume. There is no need for manual individual feeding. This saves time and increases material throughput. If required, the hopper can also be equipped with a lid to prevent material from jumping out which increases safety during operation.

Compared to many other pallet shredders, WEIMA primary crushers make it possible to feed several pallets at once. The extremely robust hopper with reinforced loading edge provides a large buffer volume. There is no need for manual individual feeding. This saves time and increases material throughput. If required, the hopper can also be equipped with a lid to prevent material from jumping out which increases safety during operation.

A proven electric gearbox motor directly drives the screw rotor and ensures continuous power transmission, while the hydraulic unit is protected. The solid technology is extremely low-maintenance, compact, and durable.

The low screw speed results in minimized noise and thus protects your environment from noise emissions. The fed material is crushed by the screw rotor and not cut by means of knives and counter-knives at significantly higher rotor speeds, as is the case with classic single-shaft shredders.

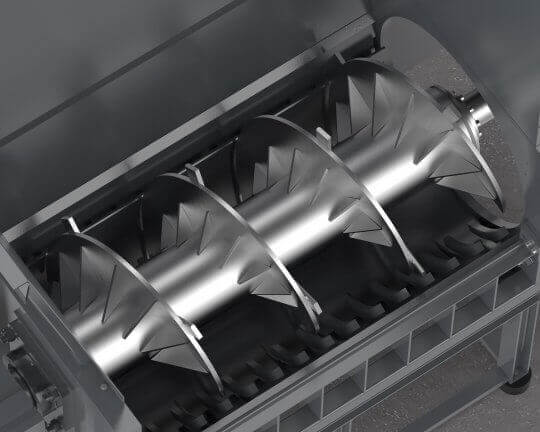

Woodwolf screw

Depending on demand or space requirements, the frame height of the crusher can be specified. This guarantees optimum discharge of the pre-shredded material by conveyor belt or into a container. It is also possible to place it directly above a secondary shredder to save space.

A WEIMA wood shredder pre-shreds wood waste in seconds.

Typically primary crushers are used for disposable pallets and Euro pallets made of wood. Removal of nails or screws is not necessary. Metals can be separated afterwards. Used furniture from bulky waste, boxes or other containers can also be easily pre-shredded. In any case, there is a significant reduction in volume, which noticeably reduces piles of production waste.

In most cases, WEIMA Crusher series pre-shredders are used within a two-stage processing plant. For example, after pallets have been pre-crushed, metal separation and secondary shredding follow. Single-shaft shredders such as the WLK 800 or WLK 1000 are suitable for this purpose. The wood chips produced can be burned directly in a heating plant or can be compressed into an even higher-quality fuel source using a briquetting press.

A crusher screw with a flight circle of 1,000 mm must have correspondingly solid bearings. For this reason, WEIMA relies on reinforced spherical roller bearings that are offset from the machine frame. This consistently prevents foreign matter from entering the bearing.

The large hopper opening provides sufficient space for fast and user-friendly feeding by forklift truck, large wheel loader, or even crane. Depending on the application, the use of a feed conveyor is also possible.

The extra-large screw auger is the heart of the shredder and is located in the machine tub, which is extremely robustly designed with 40 mm reinforced steel side walls. At the outer blade ends, the screw is fitted with welded-on knives. They can be replaced quickly in the event of wear. The proven helix shape guarantees uniform material discharge.