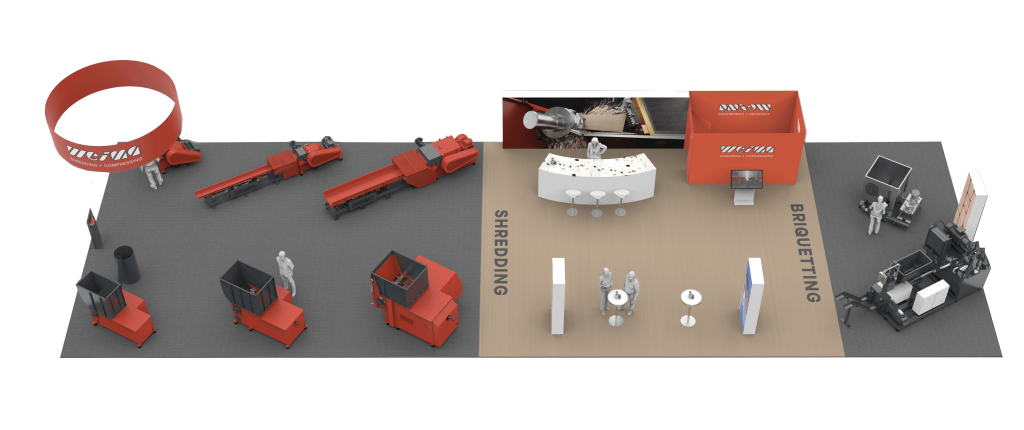

WEIMA will be attending the International Woodworking Fair in Atlanta to showcase shredding and briquetting solutions for all of the woodworking industry. We will have various sizes of shredders and grinders, as well as two briquette press models on display.

Come say hello at booth #B5953!

Scroll down for a sneak peek of our layout and to learn more about the machines we'll be presenting!

Points of interest (hover over them to learn more!)

Shredder

Horizontal Beaver 300

Wood shredder with vibratory infeed conveyor

Wood shredder with vibratory infeed conveyor

Machines in action

We'll be able to show attendees, in real-time, how some of our machines operate and what they're capable of shredding and/or briquetting.

Meet the dream team

Our most experienced professionals will be in attendance to answer all of your questions and concerns regarding our equipment. Don't be shy, we look forward to meeting you!

The WEIMA team is excited to meet you!

Informative & interactive tools

We'll have touch-screen displays that our attendees will be welcome to interact with and use to learn more about our company and services while inside the booth!

Did You Know?

This is WEIMA's biggest booth ever and we're excited to present it to the industry where it all started!

This is WEIMA's biggest booth ever and we're excited to present it to the industry where it all started!

The different series and rotor variants are the top solutions for wood shops and lumber manufacturers: Whether pallets, timber, chipboard or MDF boards, stairs, window frames, furniture, doors or semi-finished wood products – WEIMA wood waste shredders turn bulky scrap into a reusable commodity.

The benefits of wood shredding

Shredding wood waste where it’s created has many potential benefits. Space savings in production facilities is a high priority—storing bulky wood scrap takes up valuable floor space. Often this material is loaded into dumpsters for transport to an off-site location, and companies pay by the truckload and not by weight. Shredding bulky wood waste can maximize the space in these dumpsters and minimize the number of truckloads going out each month, creating an instant ROI opportunity. Certain types of wood that do not include any chemical treatments can be shredded and used as animal bedding or garden mulch in some cases—economic and environmental! No matter what, this frees up production space for more lucrative day-to-day processes rather than wood waste storage.

Homogenous wood chips after shredding

Burning round wood briquettes

Save space, energy, and money through briquetting!

Dust and shavings are natural byproducts of many wood-related manufacturing processes. This often results in messy or unsafe environments in the production area. But these materials can frequently be compressed into briquettes that are easier to handle and transport throughout a production facility.

Most of these briquettes are shaped similarly to hockey pucks and are created using only hydraulic pressure in a WEIMA briquette press. Since no glues or binders are used in this process, these materials can be burned for energy in many situations, like in facilities that use boilers for heat production. With fuel costs on the rise, this is an incredible way to save on energy costs.

Want to learn more on wood shredding?

Click here!

Customer applications and sample materials from the woodworking and wood processing industry

Sawmill cuts

Wood waste shredder

Demolition wood

Long wooden rippings

Wood veneer

Lumber scraps

Wood waste

Wood chips

Can't make the show?

Come see us anytime!

The WEIMA showroom is equipped with shredding and briquetting machines of all sizes and technologies. This enables us to simulate your application as realistically as possible. You have the possibility to send us your material or visit us directly in Fort Mill, South Carolina, where you can observe the shredding process live.

Request appointment now

Alternatively you can send us material for testing. Click here for the form.

WEIMA press

Download the formal press release here