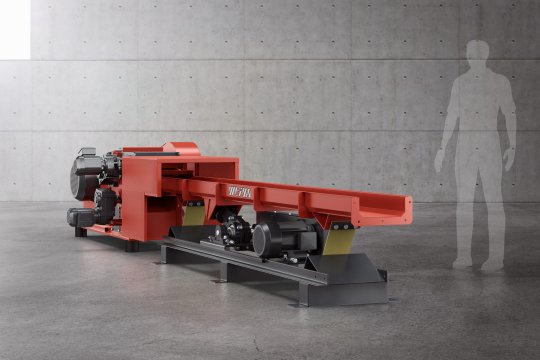

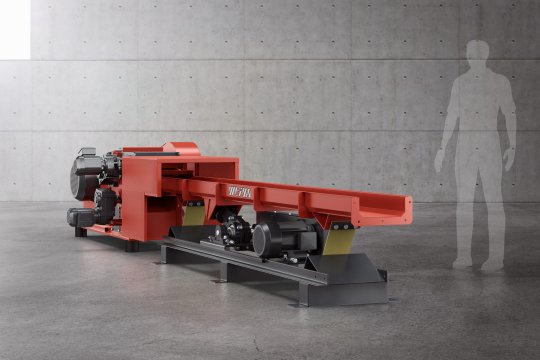

Tiger 600

The biggest difference between classic shredders and horizontal shredders is the material infeed. Instead of a hydraulic ram, an extra-long vibrating conveyor is used – with a decisive advantage: It is ideal for feeding particularly long waste such as strips, battens, squared timber, profiles, pipe material, or other linear waste. While horizontal shredders are usually placed next to the machine and can be fed manually, they come with everything necessary for fully automated production operation. They are extremely compact and robustly built. These machines are equipped for easy integration thanks to state-of-the-art data interfaces, and they are very user-friendly to maintain.

The Siemens PLC control system installed in the separate control cabinet regulates all processes of a horizontal shredder and can be individually configured for each application. This guarantees consistently high-quality throughput material of homogeneous size – ideal for further processing. If required, horizontal shredders can of course also be integrated into a fully automatic production line.

Long or wide waste materials, such as panel cuttings, often have a width that is simply too large for standard shredders. For this reason, WEIMA offers the Jumbo versions of the Tiger machines as the right solution for large-sized materials in XL format up to 1,600 mm working width. They not only have a wider feed opening, but also an enlarged rotor diameter of up to 500 mm for even more throughput.

An electromechanical drive with V-belt is used to drive the V rotor installed inside the machine. It can be maintained in a user-friendly manner and is characterized by its proven technology combined with high throughput. The absence of a gearbox or clutch also ensures low wear.

WEIMA horizontal shredders are not only particularly compact, but above all, robustly built. Rotor bearings that are offset from the machine frame are insensitive to dust, easy to maintain and durable.

Screwed underneath the rotor is a round hole screen, which can be replaced as required by a screen with a larger or smaller hole diameter in the range 10 - 80 mm. Material is shredded by the rotor until it fits through the hole openings, falls through, and is finally suctioned off. This guarantees a particularly homogeneous material for each individual requirement.

The material can be discharged from the side or rear of the machine, as required. As a rule, the shredded material is extracted via a suction nozzle and transported to a central silo. However, a screw auger can also be used as an option. Thanks to the closed system, dust emission is particularly low, which reduces the risk of explosion.

The Tiger shredders use a vibrating infeed conveyor to feed the material. It is available in various lengths (up to 40 m) and transports long strips, profiles or pipes to the infeed roller located in front of the rotor. The roller picks up the material to be shredded and transports it horizontally to the rotor, where it is shredded between the cutting knives and counter knives. The horizontal machine design simplifies material handling of long pieces. Compared to shredders with a classic hopper, the material cannot jump out in an uncontrolled manner, which significantly increases safety.

In many day-to-day activities, scraps or offcuts of wood or plastic accumulate directly at the workstation. This is also the case, for example, with panel or sliding table saws. Instead of collecting them separately and transporting them away, we recommend placing a horizontal shredder directly next to the machine. Waste can then be disposed of immediately and without additional effort.

If you want to increase efficiency in production, you also need to keep an eye on and optimize waste management. Horizontal shredders are ideally suited for use in state-of-the-art production lines thanks to their compact design and the availability of all data interfaces commonly used today. In addition, they can be operated fully automatically. Modern shredders not only reduce the volume of waste and improve material flow without manual intervention, but also reduce the cost of intralogistics. In addition, your shop floor becomes safer and cleaner.

Optimized cutting – minimum waste wood levels The kitchen worktops are stocked as unfinished templates up to 600, 900 or…

Read more

In Charleston and the surrounding area, the demand for housing is high. The company estimates that 90% of its products…

Read more