Shredding and recycling of plastic lumps and purge

Information on proper recycling of purge and plastic lumps

One of the most common material applications of plastics shredding is the processing of so-called plastic lumps, which are usually generated as a waste product during the extrusion of plastics. The economic potential of this "purge" is enormous. It is expensive to dispose of the unused purge lumps. Recycling offers the possibility of seamlessly reintegrating production scrap into the manufacturing process instead of using new resources.

Shredding plastic purge with a WEIMA S5.18 lift-up @ Plastic Recycling Inc. South Carolina

A WEIMA S5.18 lift-up single-shaft shredder shreds plastic purge at Plastic Recycling Inc. in South Carolina.

Call it what you want, we make it small.

Plastics, which accumulate as production waste at the beginning of the extrusion or injection molding process are known as plastic lumps, petrochemical lumps or extrusion lumps. It is also called "purge" in the US.

How are plastic lumps formed?

During injection molding production, there are often production waste and scrap. These occur primarily when molded parts do not meet the desired specifications, edge trims have to be made or injection molded parts are cast on. Moreover, plastic waste also occurs during production breaks, machine tests or in the start-up phases of the machines. If the waste material is pure, it can be returned to production on site. The recycling of start-up lumps reduces the amount of waste and thus effectively reduces the impact on the environment and on disposal costs.

Large, voluminous, heavy and bulky – by no means worthless

Many companies worldwide rely on shredding technology from WEIMA when it comes to the first process step of recycling extrusion lumps, for example Rowad Plastic and Napco National . Plastics manufacturers, plastics processors and chemical companies must reduce the material to a homogeneous particle size for further processing. Usually this is done by using a single-shaft shredder and downstream granulator.

What are thermoplastics?

Thermoplastics are types of plastics that are easily deformable at a defined temperature. In contrast to thermosets and elastomers, however, forming can be repeated as often as required. The only restriction is the need to avoid overheating, which would otherwise lead to thermal decomposition of the material. Well-known thermoplastics include polypropylene (PP), polycarbonate (PC), polyamide (PA), polyethylene (PE), polystyrene (PS), polyvinyl chloride (PVC) and acrylonitrile butadiene styrene (ABS).

Did you know?

The forefather of thermoplastics is celluloid. It has been known and produced the longest.

Applications from industrial plastics production

PE lumps shredding with a WEIMA S7.20 shredder @Remondis Staffanstorp, Sweden

A WEIMA S7.20 single-shaft shredder shreds large and heavy PE lumps at a recycling plant of Remondis in Staffanstorp, Sweden.

Inquire about a plastics purge shredder today

Request a quote

WLK series: High throughput plastic shredders

Machines of the WLK series are ideally equipped for a wide range of plastics tasks. The machine design is characterized in particular by durability and robustness. Thanks to the conveyor belt cut-out, all machines can be seamlessly integrated into any production line. They also offer numerous options in terms of drive and cutting geometry.

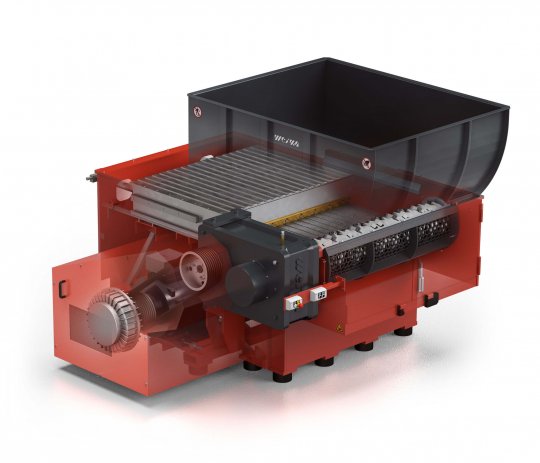

WLK 1500 shredder components overview

WKS series: Maintenance-friendly all-rounders with swing ram

With the WKS 1400-2200 series, you can shred anything: from hard, large-volume injection molding waste to tear-resistant fibers and films. The innovative inspection flap guarantees maintenance-friendly access. The swing ram optimizes material feed and thus the shredding result.

WEIMA W5.18 shredder components overview

WEIMA WKS 1800 single-shaft shredder with Hägglunds hydraulic drive shreds petrochemical lumps

WLK Super Jumbo series: For extreme throughput requirements

With their extremely sturdy design and large rotor diameters of up to 700 mm, shredders of the WLK Jumbo and Super Jumbo series offer almost unlimited possibilities for the shredding of plastic waste. They are up to any challenge and can be equipped with a powerful hydraulic drive.

A WEIMA WLK 25 Super Jumbo machine for large applications

Precise cut at high throughput with profiled V-rotor

The V-rotor developed by WEIMA is universally applicable and made of solid material. Its aggressive material feed with up to two rows of knives guarantees a high throughput with low power requirements. It can be equipped with hardened steel cutting knives in the edge lengths 30 mm and 40 mm. These can be turned several times in case of wear, which drastically reduces maintenance costs.

Heavy duty machine design

WEIMA shredders for processing highly abrasive materials can be protected with various options to reduce wear and thus downtime and maintenance costs. The heavy wall thickness of the machine frame makes WEIMA shredders particularly robust. The rotor can be reinforced with Vautid, the screen with Creusabro. To protect the cutting knives against the impact of foreign objects, large knives with edge lengths of up to 130 mm x 130 mm can be selected. If the number of knives is small. Vautid can also protect knife holders.

To avoid increased wear of the rotor face plates, we recommend the installation of replaceable Creusabro wear plates on both sides. The cutting chamber can also be reinforced and optionally lined with exchangeable Creusabro plates. Wear protection does not stop at the screen, which defines the material size. For particularly high wear, we offer a screen reinforced with Creusabro with a wall thickness of approx. 20 mm.

High-torque drive

The high-torque, multi-pole synchronous motor from Baumüller is produced in Germany and is characterized by its insensitivity to foreign objects. Without gears, the drive resists shocks and vibrations and thus has a particularly long service life – even when shredding challenging material streams.

PE lumps shredding with a WEIMA S7.20 shredder @Remondis Staffanstorp, Sweden

A WEIMA S7.20 single-shaft shredder shreds large and heavy PE lumps at a recycling plant of Remondis in Staffanstorp, Sweden.

Only at WEIMA

Heavy-duty machine design

for solid plastic lumps and rigid plastics

Adjustable counter knives

for continuously sharp cuts

Large feed hopper

for voluminous parts, without material build-up

Easy maintenance

for minimized downtimes

Many drive options

for maximum throughput

Fast service

for highest customer satisfaction

All from one source:

Machine, conveyor system, metal detection, support, spare and wear parts

See for yourself

The WEIMA show room is equipped with shredding and briquetting machines of all sizes and technologies. This enables us to simulate your application as realistically as possible. You have the possibility to send us your material or visit us directly in Fort Mill. From our gallery you have the best view directly into the cutting chamber. So you can observe the shredding process live.

Request an appointment now

Alternatively you can send us material for testing.

Click here for the form.