WLK 1500

The WEIMA WLK 1500 is designed for high throughput rates and lend themself to the shredding of almost all types of waste - especially for: Plastics. Plastic lumps, pipes, automotive scrap, blow-molded materials (PE/PET/PP bottles, buckets, pallets and containers), as well as paper, cardboard, wood and light metals. Numerous machine options ensure optimum adaptation to any application. The shredder can also be ideally integrated as a pre-shredder in a two-stage process solution.

A WEIMA WLK 1500 single-shaft shredder shreds pallets and waste wood from the production at Bropack in Dornham, Germany.

WEIMA only requires one control panel to precisely control one or more machines including the conveyor system. The built-in Siemens PLC control is optimally adapted to the shredding process. Various slide controls and rotor settings can be conveniently adjusted to the desired application. All control cabinets are designed in-house and built in our German production facilities.

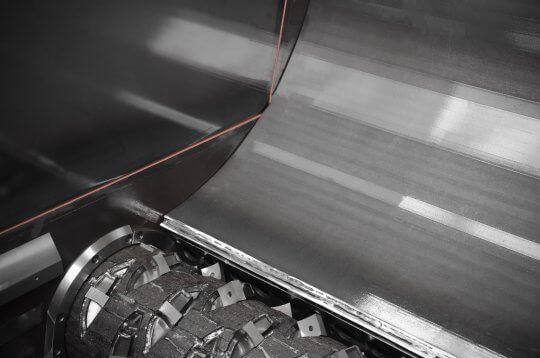

The interaction between the cutting knife and the counter knife has a significant influence on the material throughput and the shredding result. To maintain a perfect cutting gap even with natural wear, counter-knives of this series are manually adjustable as well as reversible. Optimum cutting geometry keeps shredding energy-efficient, minimizes wear costs, and significantly extends the service life of the knife.

Many of our customers describe the profiled V rotor as a best in class for shredding. The material intake is optimally designed with two rows of knives. The V rotor stands for high throughput rates, low energy consumption, reduced thermal stress and low wear costs.

A WLK 1500 single-shaft shredder shreds Big Bags. An EREMA Intarema Extruder further reduces the shredded Big Bags into granulate.

The F rotor impresses with its controlled infeed behavior and its precise cutting geometry – especially with flexible materials such as films, filaments or veneer. It can be equipped with either bolted-on or welded knife holders. In addition, a robust wear protection made of Vautid is possible for more abrasive materials.

WEIMA F rotor for flexible materials

The ram feed can be controlled manually, cyclically, or load-dependently. Depending on the application, it makes sense to supplement the classic material ram with more technical options. To prevent possible jamming and improve its guidance, the ram can be guided on rollers. In addition, WEIMA recommends the use of a segmented floor – especially for very thin materials.

At Yangil Enpla in Incheon, Korea, a WEIMA WLK 1500 single-shaft shredder is used to shred fishing nets and other fibers for recycling and the production of regranulate.

The shredding of particularly resistant materials requires correspondingly robust bearings that are easy to maintain. WEIMA uses long-life, spherical roller bearings, whose stable design and offset mounting from the machine frame protects against impacts and uncontrolled power transmission. Their additional shaft seal ring effectively helps against the intrusion of contaminants or dust.

Adapt the screen to your needs. The smaller the hole diameter, the finer the shredded material that is discharged. Screens can be exchanged flexibly and are bolted as standard.

Machines with a conveyor belt cutout make material discharge clean and efficient – ideal for production lines. For example, conveyor belts up to 600 mm wide can be seamlessly integrated. Alternatively, material can be discharged via suction or screw conveyors.

For most applications, electromechanical drives are the classic choice because they are easy to maintain and robust. WEIMA's special feature: we manufacture our own gearboxes that are specially designed for shredding operations. Torque monitoring and shock-absorbing vibration dampers round off the package. A hydrodynamic start-up clutch is available as an option for further protection of the machine.

The ram of a shredder is moved back and forth hydraulically. With turbo hydraulics, this happens even faster. For continuous operation, additional oil cooling and a length measuring systems are available upon request.

Vibration damping machine feet for less vibration in the building

Thanks to compact feet made of hard rubber, there is no need to anchor the machine to the plant floor. The installation remains flexible. More importantly, disruptive vibrations that negatively affect the surrounding area are effectively avoided.

The WLK 1500 single-shaft shredder shreds voluminous bales of paper waste, cardboard and paperboard for the production of insulation material.

Instead of classic angled hoppers, WEIMA has relied on a design that is rounded along the front side for many years. This has two decisive advantages: the feed volume is increased. In addition, disruptive material bridges are effectively avoided – these occur especially with large material pieces. In this case, the shredder cuts itself free.

To achieve ambitious sustainability targets, UNILIN Insulation relies on a WEIMA WLK 1500 shredder at its site in Desselgem (Belgium) for shredding production scrap and waste from insulation board production. The distinctive feature is the hydraulic tilting table, that can feed panels up to 5.5 meters long into the shredder.

Read more

Kloboucká lesní shreds wood waste from the production of glued laminated timber with a WEIMA WLK 1500. From this, high-quality pellets for heat generation, which they distribute themselves – an additional income source that is also sustainable for the environment.

Read more

Producing paper products generates a lot of waste. In the classic recycling cycle, the production waste or surplus is shredded and then returned to the production process. The Munich start-up company easy2cool has a different but equally sustainable use for paper waste. Using a WEIMA WLK 1500 Shredder, revolutionary and sustainable insulating elements are made from corrugated cardboard packaging.

Read more

In the course of growth and expansion to four different locations, Bropack Bronner Packmittel GmbH decided to build a new headquarters. Together with WEIMA Maschinenbau GmbH, Steiner GmbH, Nolting Holzfeuerungstechnik GmbH and Mühlböck Holztrocknungsanlagen, an innovative system was designed for an in-house drying and heating system.

Read more

Grayson Lumber has successfully integrated a WEIMA shredder into its operations to process wood waste generated during lumber production. By utilizing the shredder, Grayson Lumber has found an innovative solution to repurpose wood waste, which is then utilized as fuel in an on-site boiler.

Read more

In Exeter, UK, Devon Contract Waste recycles a wide variety of hard plastics. This includes not-so-everyday items such as fuel tanks, kayaks and road cones. The central component of the recycling plant is a WEIMA WLK 1500 single-shaft shredder.

Read more