On September 12th-18th, the machine tool industry will convene at the International Manufacturing Technology Show in Chicago, Illinois! WEIMA is looking forward to displaying size reduction machinery relevant to this industry, including a debut machine for handling and compressing metal swarf with ease.

Come see what's new from WEIMA at booth #339082!

WEIMA has a world of size reduction machinery and scrap handling solutions for the machine tool industry and beyond!

Scroll down to learn more about the machines we'll be presenting at the International Manufacturing Technology Show in Chicago, Illinois!

Hover over the dots for more information.

TH 600M Briquette Press

Makes 60 mm briquettes from loose metal and has catch pan for cutting fluids.

TH 600 M

Touchscreen monitor

Explore and engage WEIMA's metal recycling capabilities.

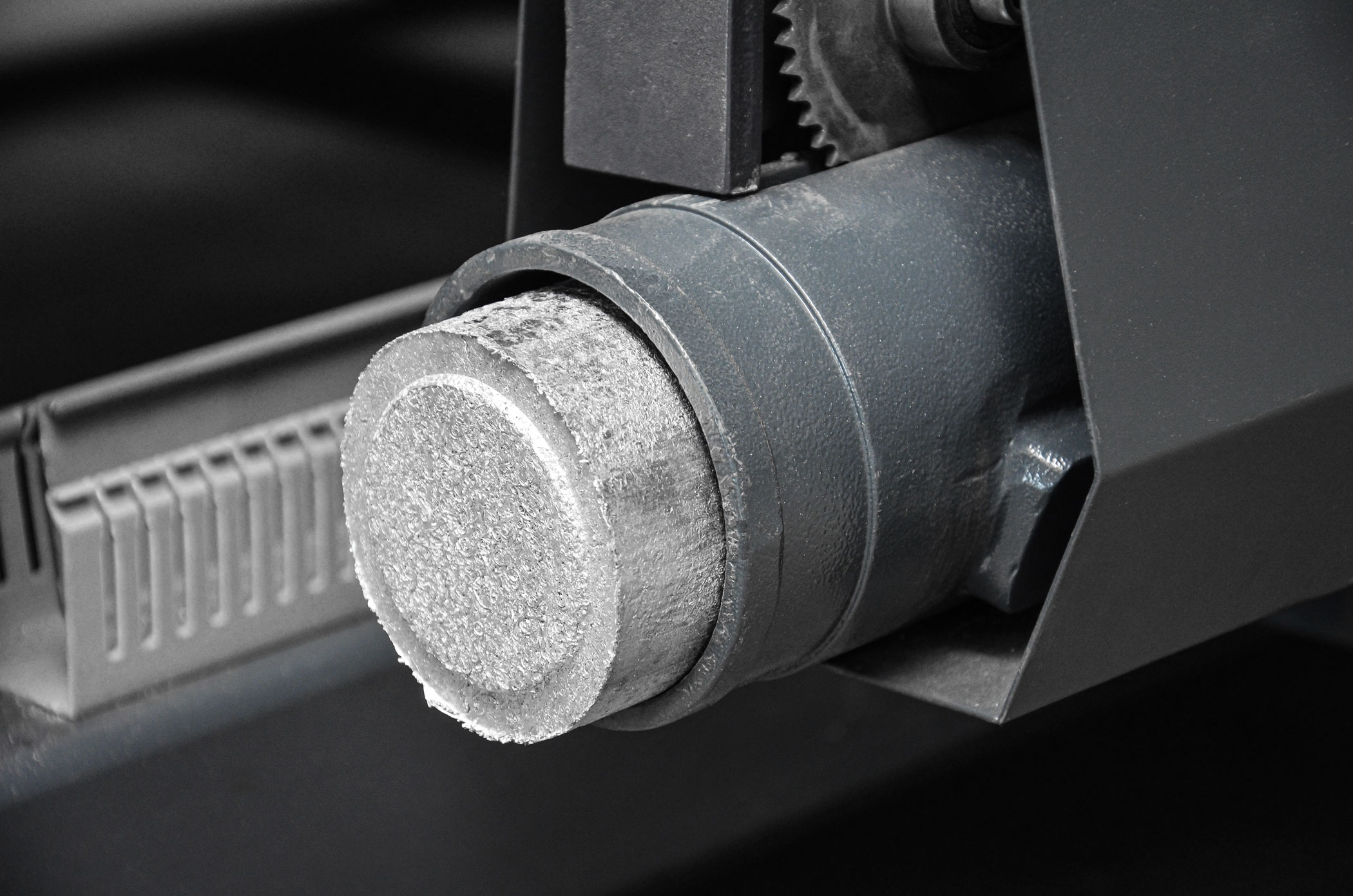

C. 200 Swarf Press

Compresses metal turnings into 200 mm discs while collecting fluids for easy recycling.

WEIMA PUEHLER C.200 New hydraulic press for compacting shavings from CNC machining

WEIMA is officially debuting a BRAND NEW solution for handling the metal swarf that's created during various processes, including turning, milling, sawing or drilling. This natural byproduct is often bulky, sharp, and dangerous for employees to handle. Once compressed, these densified birds nests are ejected from the machine in the form of discs with a diameter of 200 mm. In this form, they can be recycled, smelted, or stored with ease.

This BRAND NEW machine does it all

The machine that makes this all possible is called the PUEHLER C.200, and it is making its grand debut at IMTS 2022! It can be directly positioned under a chip conveyor, allowing sharp and dangerous metal swarf to fall into its hopper.

The metal is compressed and dewatered in a single step, making it easy and efficient to reclaim expensive cutting fluids. The fluid is collected in a tray below the pressing chamber, making it simple to recycle or reuse this valuable liquid.

The brand new PUEHLER C.200 from WEIMA

Want to learn more about metal compression and coolant reclaim?

Click here!

Take a sneak peek!

The PUEHLER C.200 from WEIMA is revolutionizing how machine tool businesses handle their turnings, swarf, and birds nests. From collecting and compressing to draining and and fluid reclaim, this machine does it all in a single step.

The WEIMA team is also bringing a TH 600M briquette press to IMTS, which was designed specifically with metal applications in mind. This machine transforms loose chips, turnings, or shavings into dense briquettes. This saves significant space and increases the resale value of this valuable material, due to decreased burn-off during the smelting process.

Reclaim valuable metals and cutting fluids

As the briquettes are compressed-- using only hydraulic pressure-- the emulsions and cutting fluids are pressed out of the material. The catch pan beneath the WEIMA TH 600M briquette press collects this expensive liquid, allowing companies to recycle or reuse it. This results in significant cost savings.

See how Mastel Aluminium-Halbzeuge GmbH in Talheim is utilizing a WEIMA briquette press for metal reclaim.

Read the story here!

Swarf compression

Compressing loose metal swarf is beneficial for so many reasons. The sharp birds nests are hard to handle and often dangerous. Dropping them directly into a hopper with minimal handling increases safety and saves time. Metal turnings and chips are valuable materials that can be compressed, smelted, recycled, etc.

Metal shavings taking lots of space in containers

When the briquettes of swarf are compacted, the cutting fluid is separated and collected in a catch basin on the WEIMA briquette press.

Coolant reclaim

Coolant, emulsions, or other cutting fluids are valuable and expensive. Reclaiming them is a great source of ROI, if only you have the tools to do it. WEIMA machinery is made for this job. While metal swarf is compacted into manageable discs, WEIMA compression machinery is made to collect the fluid that is squeezed out of this materials, allowing companies to reuse or recycle this resource as well.

Light alloy briquettes

Aluminum briquette

Briquettes from light metal shavings

Aluminum briquettes

WEIMA knows metals recycling

A full team of WEIMA sales professionals will be in Chicago for IMTS 2022, and with them comes a wealth of experience. With decades of experience between them, they know what the machine tool industry experiences on a daily basis. This knowledge allows them to provide solutions that are relevant, efficient, and effective.

<br

WEIMA metal recycling experts

What's a technology show without technology?

Attendees are free to use our cutting edge touch-screen display at our booth to discover more about the machinery on display as well as WEIMA's other recycling capabilities.

Can't make the show? Come see us in South Carolina!

The WEIMA showroom is equipped with shredding and briquetting machines of all sizes and technologies. This enables us to simulate your application as realistically as possible. You can send us your material prior to your visit in Fort Mill, South Carolina, where you can observe the size reduction process. This gives you the utmost confidence that we know your business and can help you reach your goals!

Request appointment now

Alternatively you can send us material for testing. Click here for the form.

WEIMA press

Download the formal press release here