TH 1500 M

For reliable and economical volume reduction. The TH 1500 M briquette press compresses material within a matrix. This ensures the briquette is formed in a consistent shape and then discharged through a two-sided discharge.

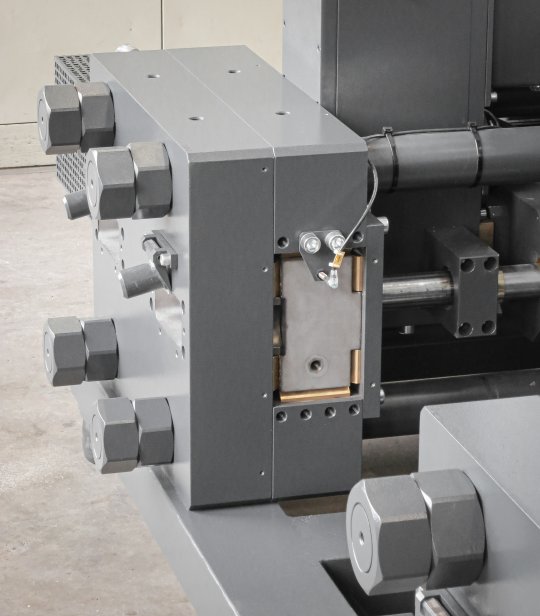

The movable matrix in which the final briquette is formed is subject to increased wear. For this reason, it is made of hardened steel and is also chrome plated. The press plate next to it can be replaced in just a few steps after wear. This ensures a smooth process.

A WEIMA TH 1500 M briquette press compresses wood chips and dust into dense wood briquettes in mere seconds.

Maximum flexibility. For quick parameter adjustments (e.g. briquette length, number of briquettes per minute, density, etc.) during material changes, the large TP 600 touch panel with Siemens S7 PLC control can be swiveled in many directions and operated ergonomically. It also visualizes various processes in the machine. To ensure that the electronics are optimally matched to the machine, we design, build, and wire our control cabinets completely ourselves. We only use high-quality brand components – for example from Siemens, Allen Bradley or Rittal.

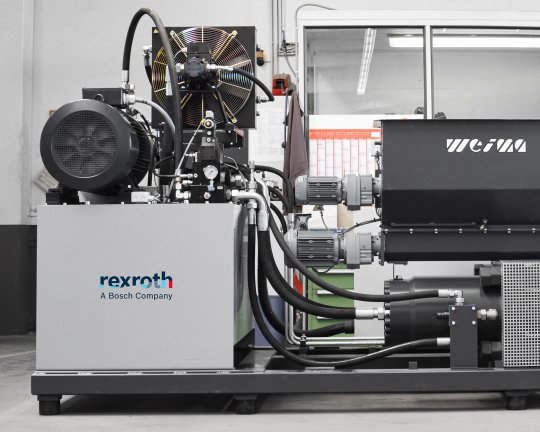

The powerful axial piston pump of the hydraulic unit delivers an output of up to 37 kW. This allows the buildup of particularly high press pressures, resulting in extreme compaction of the briquettes produced. The remaining hydraulic components are also reinforced. The result: a longer service life and decreased maintenance costs. However, for those who require significantly less power depending on the application, motors starting at 5.5 kW are also available.

Accumulating wood waste is shredded in a WEIMA WL 8 single-shaft shredder and granulator. The shredded wood waste is then transformed into sellable briquettes with the help of a TH 1500 M briquette press.

The separate oil tank of the Bosch Rexroth hydraulic unit has a capacity of approx. 1,000 liters (TH 1500 M) and is equipped with efficient oil cooling. Due to this large quantity, the quality of the hydraulic oil can be maintained at a very high level for a long time - this is ideal for use in multi-shift operations.

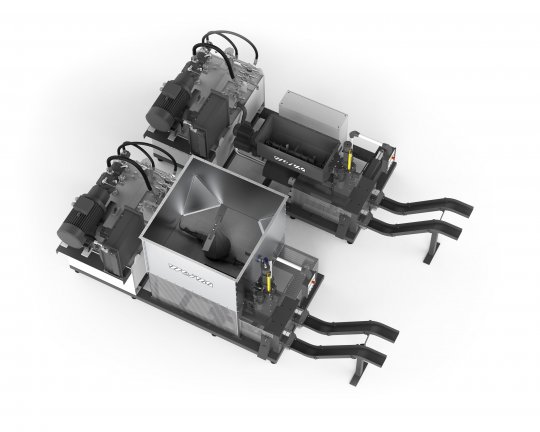

To avoid mechanical damage, the screw conveyor located at the bottom of the feed hopper is suspended on a robust cardanic joint. It transports a defined quantity of material into the compaction chamber, where pre-compaction already takes place. This shortens the pressing time, resulting in a higher briquetting output.

All WEIMA briquettes are characterized by their dimensionally stable form. By using matrix technology, even better compaction and volume reduction can be achieved compared to pressing clamps. Depending on the application, the briquettes are then so dense that they even sink in water. They therefore have a density >1 (e.g. for aluminum a density of approx. 2.3, for other metals considerably more). Therefore, briquettes of TH Industrial series are ideal for subsequent selling. Their rectangular shape also makes them easy to handle, as they can be stacked for transport.

A WEIMA WLK 1500 single-shaft shredder shreds aluminium waste. A WEIMA TH 1500 M briquette press then compacts the aluminum chips into dense metal briquettes.

Optimally connected: WEIMA briquetting presses have all common interfaces to ensure fast integration into new or existing production lines. Machines of the TH Industrial series can be operated autonomously and in multiple shifts in automatic mode. Production parameters can be flexibly adjusted, for example in case of material changes.

The use of a closed matrix for compacting loose chips, dust, or shredded materials, combined with a powerful hydraulic unit, results in extremely high briquette densities. TH Industrial series machines are state-of-the-art and extremely robust in design. Depending on the specific material, the throughput capacity is up to 700 kg/hr (TH 1500 M).

Depending on your needs, you can choose between a large-volume feed hopper for flexible filling by means of a forklift truck or lifting and tipping device, or compact material buffers (chip agitator) for continuous, mostly automated filling, where the material falls directly into the screw conveyor channel. Both hopper systems can be equipped with a practical level gauge that safely switches the machine into standby mode when idle until new loose material is fed in again.

The TH 1500 M produces rectangular briquettes in the 150 x 60 mm format. The briquette length can be variably adjusted on all machines. No binders or adhesives are used for compaction, only hydraulic pressing pressure.

The powerful WLK 1500 single-shaft shredder processes wood pallets and wood chips. A metal detector separates out nails and screws along the way, so that the WEIMA TH 1500 Duo briquette press can finally produce dense wood briquettes from the shredded material.

It is very busy here. Every day 3,000 wood briquettes pass through the conveyor belts of the Augustinuswerk. Through further…

Read more

Shavings occur wherever planing work is done. If you replace planing with cutting, this statement applies accordingly to the imposing,…

Read more

The company itself is nestled in the outskirts of Lynchburg and has only seven employees. Once they get the call…

Read more