In the bustling city of Houston, Texas, a brewing pioneer emerged, capturing the hearts of beer enthusiasts. Saint Arnold Brewing Company, renowned as Texas' oldest craft brewery, embarked on a flavorful journey when their first beer shipment set sail in 1994. Since that time, the brewery has become a beloved institution in the region.

Craftsmanship in the Heart of Houston

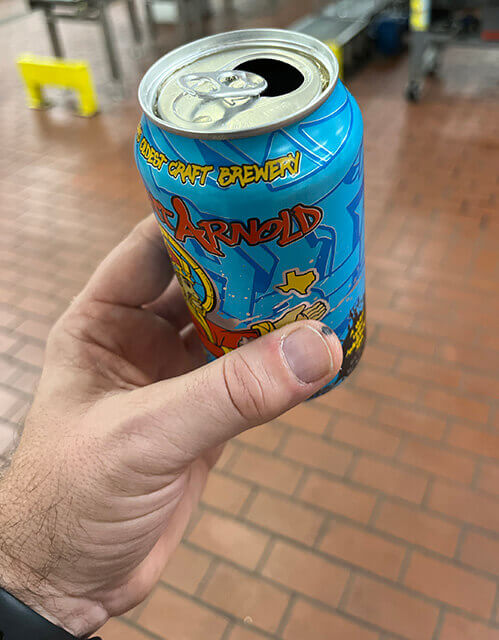

Nestled within their vibrant brewery campus, Saint Arnold mastered the art of beer production, from the meticulous brewing process to the precise filtering, kegging, packaging, and, of course, the delightful act of drinking their soulful creations. Their commitment to crafting full-flavored beers and their distinctive, colorful labels set them apart from the crowd. One thing is clear: brewing beer is their true passion.

About Saint Arnold Brewing Co.

01

TX

Houston

02

E.200

Drainage press

03

1994

Founded

A Perfect Match: Saint Arnold Brewing Company Discovers the WEIMA E.200

As the company's popularity soared, so did the need for sustainable solutions to address the challenges posed by excess waste. During their visit to the Craft Brewers Conference in Denver, Colorado, the team from Saint Arnold discovered a game-changing ally in their quest for environmentally friendly practices: the WEIMA E.200 Drainage Press.

The empty, damaged cans are fed by hand into the WEIMA E.200.

The challenge: They were grappling with an abundance of underfilled or damaged cans that were accumulating within their facility, occupying precious storage space and hindering efficient operations.

The Versatility of the WEIMA E.200

The WEIMA E.200, a cutting-edge universal hopper with a sizable infeed capacity, proved to be the perfect fit for Saint Arnold's needs. Despite space constraints in their brewing facility, the brewery strategically placed the free-standing WEIMA machine on-site. The damaged cans were manually loaded into the hopper, which swiftly compressed them, reducing their volume and liberating valuable space.

From Storage Woes to Space Optimization

Previously, Saint Arnold had been storing the damaged cans in bulk at their warehouse before shipping them off to a recycling facility. With the introduction of the E.200, however, they could now crush the damaged, unfilled cans right within their premises, significantly reducing the frequency of shipments to the recycler. This not only streamlined their logistics but also minimized transportation emissions, aligning with their commitment to environmental sustainability.

The discs take up significantly less space than the empty cans.

Did you know? This brewery was named after Saint Arnold, the Patron Saint of Brewers.

A Partnership Rooted in Sustainability

The partnership between Saint Arnold Brewing Company and WEIMA was forged on the shared values of sustainability and innovation. Saint Arnold's dedication to environmental responsibility was evident in their popular "Recycle Rewards" program. By incentivizing customers to return printed cardboard six-pack carriers for reuse, they not only reduced waste but also enjoyed cost savings by repurposing these expensive carriers. As a bonus, patrons of the brewery can join in on these recycling efforts.

The filled cans are capped and are sent to be packaged and shipped.

The incorporation of the WEIMA E.200 seamlessly complemented Saint Arnold's sustainability goals. By harnessing the power of this cutting-edge machine, the brewery maximized their recycling efforts while optimizing operational efficiency. With the ability to focus on their core competency of brewing exceptional beer, Saint Arnold Brewing Company showcased that the perfect balance between economic viability and environmental stewardship could indeed be achieved.

A Toast to a Greener Future

The collaboration between Saint Arnold Brewing Company and WEIMA was a testament to the marriage of sustainability and innovation. Through the utilization of the WEIMA E.200 Drainage Press, Saint Arnold enhanced their waste management process, efficiently compressing damaged cans and reclaiming valuable space. Their unwavering commitment to sustainable practices and responsible brewing solidified their position as industry leaders.

With each crushed can, Saint Arnold Brewing Company and WEIMA toasted to a brighter, greener future, exemplifying that excellence in brewing could harmonize with environmental preservation.

Contact

Contact

Sign-up for our newsletter

Newsletter

Sign-up for our newsletter and get all the latest updates in your mailbox

Sign-up for our newsletter