E.200

The WEIMA E.200 is your economical introduction to drainage technology. It produces pellets with 200 mm diameter. Drainage presses of the E series work electro-hydraulically by means of different hydraulic cylinders. The material is fed manually through the curved feed hopper. The pressed out liquid or paste is collected in a collecting trough and can be drained by a separate pump. Cleaning and maintenance is particularly user-friendly. WEIMA presses are resistant to contaminants.

At Saint Arnold Brewing Company they use a WEIMA E.200 press to compact their unusable beer cans from their production.

To make the start as comfortable as possible, all presses of the E series are delivered pre-programmed and ready for operation as a plug-and-play solution. For the installation, only a power and water connection is required. On request, we also offer the setup and commissioning of the machine (including training) via digital channels.

For highly flexible use in your plant, the compact presses of the E series can be moved on lockable rollers to the respective place of use and can be used there directly. Temporary use outdoors is also possible, as the machine has been designed according to IP 65 standard.

Parameters (e.g. pressing time, pressing force) can be quickly adjusted via the color display of the built-in PLC control. The re-pressing function can also be set in a user-friendly way via the PLC control. This programmable holding time is particularly necessary for pressing absorbent materials. This is the only way to produce permanently dimensionally stable discs.

Thanks to level sensors in the feed hopper, the press can be used automatically. The machine switches on automatically when a certain filling level is reached in the hopper. To prevent wear on machine components, the machine automatically switches to standby as soon as the filling level falls below a certain level.

To compensate for temperature differences in the hydraulic oil, machines of the E series have an oil cooling system with water using the heat exchanger method. This ensures long operating times without downtime. The heat exchanger is installed in the hydraulic housing and thus is protected against contamination.

The inclined discharge pipe allows the formed discs to be discharged at an elevated level – directly into a large bin or tipping trough. This saves the use of a conveyor belt. Depending on requirements, the discharge pipe can be configured straight, to the left or to the right.

Thanks to brakable rollers, the E series machines can be used flexibly during operation. This ensures optimum access to the machine also during cleaning and maintenance. A maintenance and cleaning hatch on the hopper facilitates access to the inside of the machine.

The most important components of the hydraulic unit have been designed particularly generously to always have a buffer to fall back on, even under full load. Among other things, this results in lower heat generation and makes the machine significantly less susceptible to foreign matter.

The curved hopper prevents cans or other materials from escaping from the machine during the pressing process due to the enormous pressing force. In addition, the curved shape facilitates cleaning and prevents uncontrolled spraying of pressed-out liquid from the filling opening.

By default, only food grade hydraulic oil is used in these machines. If required, a customer-specific hydraulic oil can also be used.

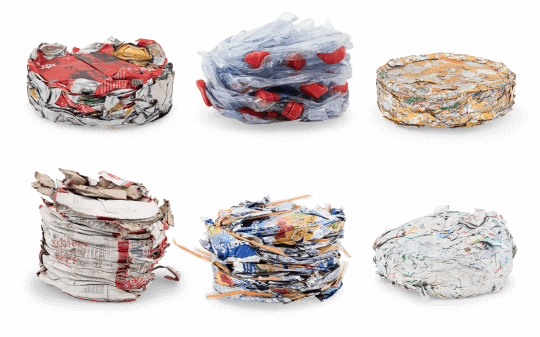

With WEIMA's compact packaging presses, you can open filled disposable packaging, separate the contents from the packaging and press the packaging material in a single operation. This way, cans, PET packaging, soft packaging, beverage cans, cream spray cans, TetraPaks, wet wipes, hygiene and cosmetic products and much more can be drained, separated and compressed at the same time.

Saint Arnold Brewing Company found the ideal solution to their excess waste challenges with the WEIMA E.200 Drainage Press. By compressing damaged cans on-site, they are demonstrating their unwavering commitment to sustainability and innovation within the brewing industry.

Read more

Fiddlehead Brewing Company integrated a WEIMA E.200 drainage press into their existing canning line to puncture, drain, and compress any out-of-spec aluminum cans that are rejected during quality control. This is a hands-off solution to effective product destruction and recycling.

Read more