At GARANT, sustainability is a top priority. For many years, the products have been manufactured in an energy-conscious and environmentally friendly manner. Waste from frame production is also processed further – with a WEIMA WL 6 S single-shaft shredder.

GARANT Türen und Zargen GmbH is one of the leading companies in the door and frame industry. The company was founded in 1991 and employs a staff of around 480. The production and storage area in Amt Wachsenburg, Thuringia, measures approx. 66,000 m2. That is where 3,300 doors and almost as many frames are produced daily. The portfolio includes standard as well as designer doors in a wide variety of styles as well as matching frames. Many different materials are used. However, one of the most important materials is wood.

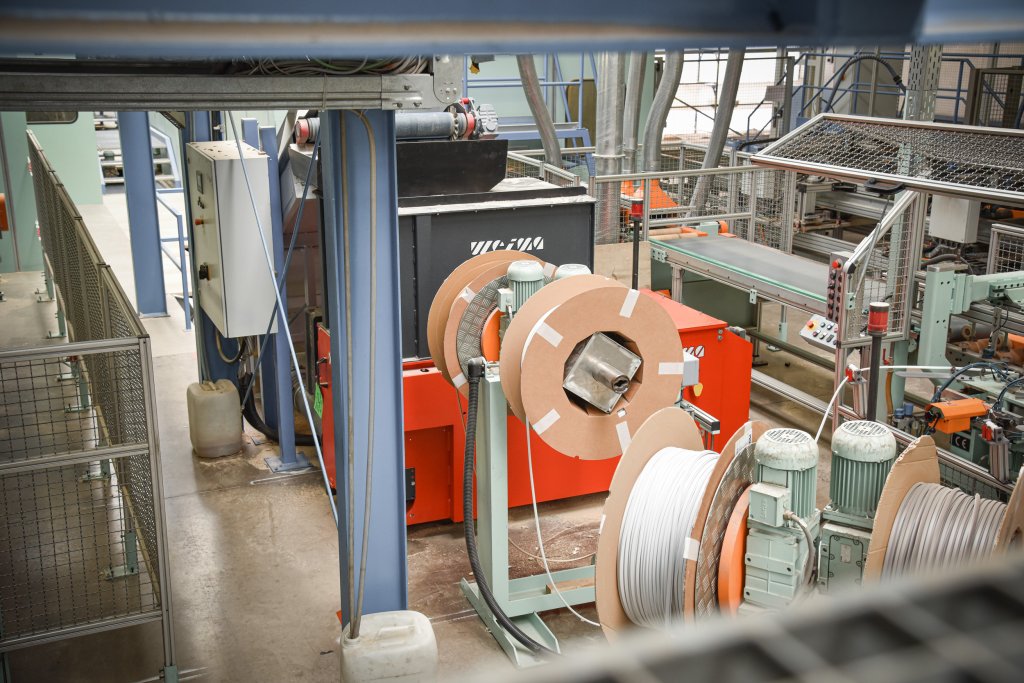

The WEIMA WL 6 S single-shaft shredder

Environmental mindfulness

A conscious use of the forest resources is a given at GARANT. All wood products are both PEFC and FSC certified. The energy management is also certified according to ISO 50001. In order to meet the strict requirements of these certificates and to make a contribution to environmental protection, GARANT continuously records and analyzes the material flows in the production halls. Measures that increase material efficiency and the recycling rate can thus be implemented quickly. The amount of waste is also continuously monitored and, where possible, reduced. A consistent step was the purchase of a single-shaft shredder from WEIMA. In July 2019, a WEIMA WL 6 S shredder was added to GARANT’s sophisticated disposal concept.

Once the hopper is filled, the shredder goes into automatic mode.

Shredding without the touch of a button

The wood shredder is perfectly integrated into the production line. In the fully automated frame line, state-of-the-art production machines ensure precision and quality. The cutting of the frame elements is completely computer-controlled. The wood waste from the frame production is discharged via conveyor belts and transported to the shredder on a central conveyor line. As soon as the hopper of the shredder is filled, the machine goes into automatic mode and shreds the wood waste to a homogeneous material size.

Reliable shredder for industrial standards

The WEIMA WL 6 S is a proven classic in the product portfolio of the shredding specialist from Ilsfeld. With a rotor diameter of 368 mm and a rotor length of 800 mm, the WL 6 S shreds wood waste of all kinds. The profiled V-rotor is made of solid material and is mounted in stable rotor bearings. This guarantees high throughput with low power requirement. Of course, a strong drive is just as important. The WL 6 S is equipped with a WAP gear developed by WEIMA. This is particularly insensitive to foreign materials and is low-wear. The produced wood chips can be transported out of the machine by means of an extraction system or transport screw.

The shredder is perfectly integrated into the production line.

At GARANT, the WL 6 S is connected to an extraction system that conveys the wood chips into a central chip silo. Finally, the shredded wood waste is used in a biomass combustion plant, producing enough heat for all buildings on site. This is resource-saving and cost-saving.

A further WEIMA shredder from the ZM series has already been ordered and will be delivered to the door and frame manufacturer in the middle of the year. This will enable GARANT to use the wood waste efficiently in other production lines as well and to further pursue its sustainability goals.