AmeyCespa is one of the leading providers of recycling, composting, anaerobic digestion and waste management services. The company combines the expertise of Amey, the UK’s leading public service provider, and Cespa, Spain’s major waste management company, which has over 40 years of expertise in the field. In Waterbeach, which is located only a few miles north of Cambridge (England), two WEIMA PowerLine single-shaft waste shredders were recently installed. They are used for secondary shredding in the Mechanical Biological Treatment (MBT) plant.

There is always rush hour on the AmeyCespa plant site – every single day. The activity is mainly caused by the shuttling garbage trucks that are collecting municipal waste all around the famous university town of Cambridge and transporting it to the Waterbeach recycling center.

Picture 1: AmeyCespa headquarters, Waterbeach (England)

It is not yet obvious that these loads of waste in the loading area are meant to be cash in the near future and are connected with environmental protection. But before they can turn into profit, they have to be sorted.

To do so, AmeyCespa is able to feed up to three pre-shredders, crushing the pre-sorted material to a size that is able to be processed. After that, the main objective is to get rid of foreign materials such as stones and to aggregate materials – film to film, metal to metal, wood to wood…

Picture 2: WEIMA PowerLine 2000 and PowerLine 3000

To achieve this, state-of-the-art windsifters, ballistic separators, metal detectors and drum screens– that divide the shredded material into several fractions– are utilized. The so-called light fractions, consisting of paper, film, foam and small organic pieces, get to the two WEIMA PowerLine shredders by conveyor belts.

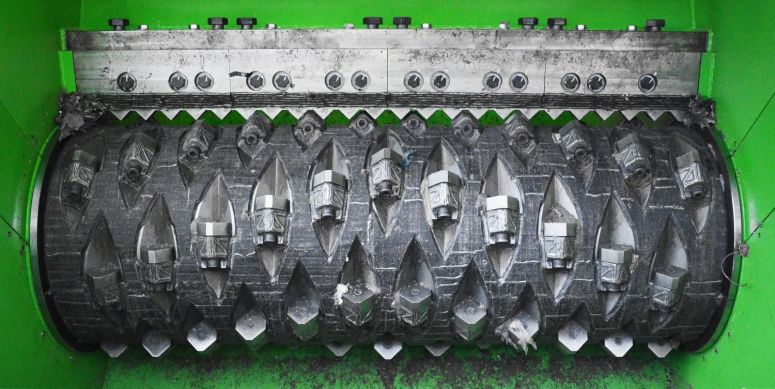

Picture 3: PowerLine Rotor with 80x80mm cutting knives

The very high output and flexible universal shredders– with a weight of 25 / 35 tons– shred the material to a size of 100mm by using a special PowerLine rotor with vautid coating for wear protection and 80x80mm cutting knives.

Both machines are equipped with a hydraulic drive (with 160/255 kW performance) representing a strong drive option for WEIMA size reduction machinery. It features a simple design, offering an extremely high torque potential. This enables these machines to be driven by a smaller kW-rated motor, saving considerable operating costs. Moreover, they assure an interruption-free and low-maintenance operation.

Picture 4: Hydraulic drive WPL 2000

The hydraulic drive provided full torque from zero to maximum speed in both forward and reverse, and speed control from zero to full speed. In comparison to electromechanical drives with gears, hydraulic drives are extremely resistant to foreign bodies. With their built-in overload protection, they resist both constant shock loads and stalling conditions. This safeguards not only a shredder’s components, but also reduces downtime while increasing reliability.

Picture 5: Storing and drying

When the material stream has been shredded to the optimal size, it is further conveyed to the warehouse next door, which is about the size of three football fields. There, the shredded goods can be carried away after drying.