PreCut

The PreCut single-shaft shredders (pre-shredders) are built to handle unsorted, highly contaminated waste streams. This machine is the ideal first step for a multi-stage waste processing system. After unsuitable material has been sorted out, the pre-shredded material can be further processed in optimum form. Ideal for multi-stage processing with high throughput. The PreCut ensures optimum preconditioning of the material for further processing steps such as sorting, classification and separation.

The mechanical-biological waste handling process is a standard method for residual waste. Burnable materials can be prepared in a way so that they can be used as energy. This machine is the first step in an operation with a variety of materials to process. After the foreign materials (such as stones and metal) have been sorted out, only what remains will enter the hopper, and the first step in the size reduction process can begin!

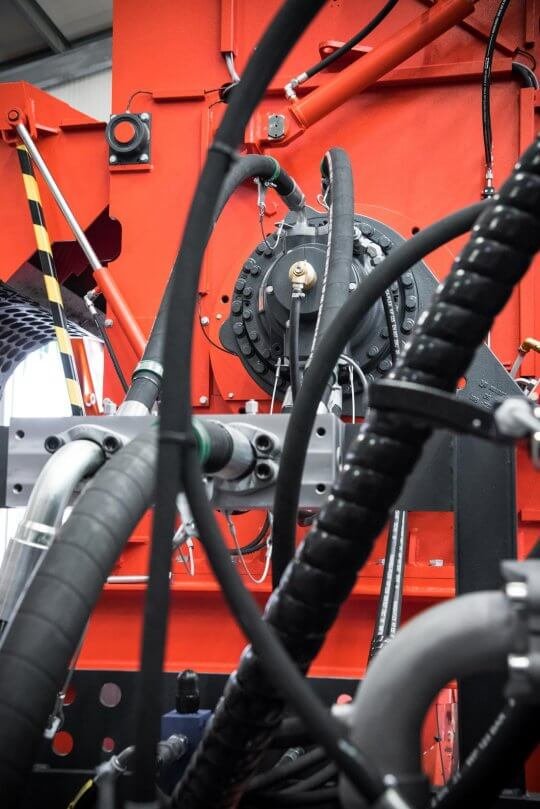

A WEIMA PreCut 2000 single-shaft shredder pre-shreds municipal solid waste for the production of refuse-derived fuels (RDF). Secondary shredding happens with a WEIMA PowerLine 2500 single-shaft shredder. Both shredders are equipped with a hydraulic drive by Hägglunds Bosch Rexroth.

Powerful hydraulic drive from Hägglunds

A powerful WEIMA PreCut 3000 single-shaft shredder shred old textiles at Tosung in Chilgok, South Korea.